InDro’s VR humanoid draws crowds at MWC26

By Scott Simmie

InDro is proud to be displaying, alongside Ericsson, at the huge Mobile World Congress (MWC26) in Barcelona. It’s a massive show, highlighting connectivity and the near-endless variety of solutions that rely on it: Everything from industrial robots and other Industry 4.0 innovations through to AI-powered smart glasses and the myriad of other devices that can help enhance life at home.

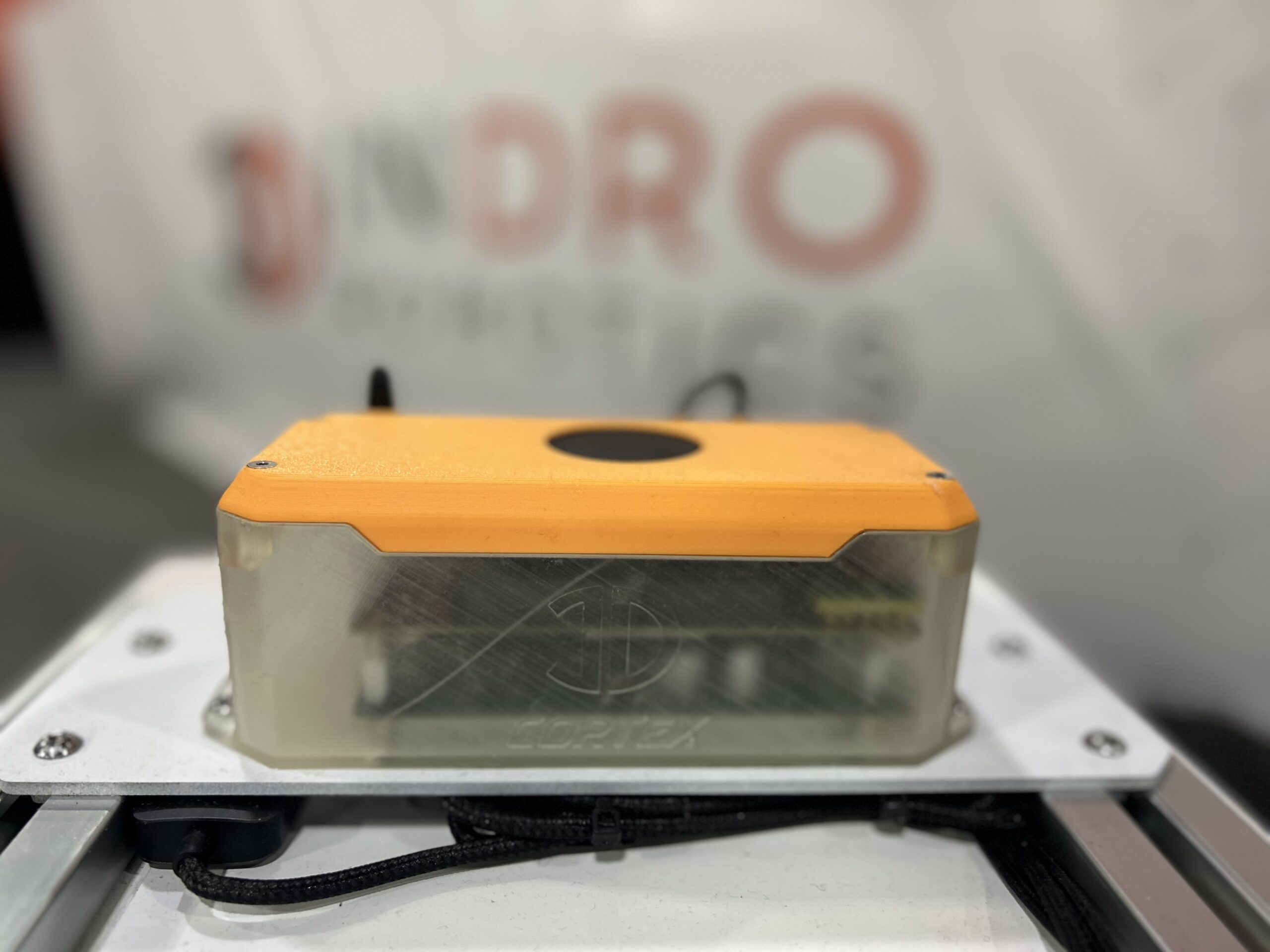

We’re alongside Ericsson Enterprise Wireless Solutions – which is demonstrating the power of its Ericsson Private 5G network, or EP5G. It’s the solution for the growing number of companies and sectors that need their own secure, high-bandwidth and ultra low-latency networks to enhance data processing, speed and efficiency. Problem is, you can’t actually *see* what a private 5G network looks like. InDro is on the scene to provide, in a tangible way, a look at what such networks enable.

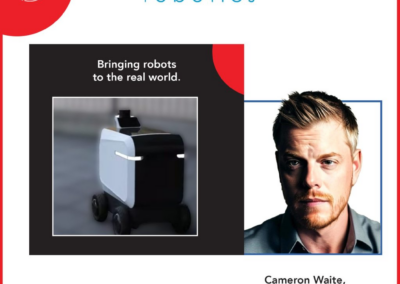

In this case, we have a humanoid that can be remotely operated over 5G or WiFi using a high-resolution headset and hand controllers. It’s being operated at the show by InDro Forge Hardware Engineering Manager Joel Koscielski. It’s a perfect solution for situations where you might not want to put a person at risk.

“Connected through EP5G, the system essentially allows a highly trained technician to physically embody the robot and perform a series of actions. It’s really been a crowd pleaser so far, and we think it’s a critical stepping stone,” says InDro Head of R&D Sales Luke Corbeth, who’s also on the scene.

Ericsson also invited Canadian company Cypher Robotics. InDro has incubated Cypher and assisted with the development of its breakthrough Captis system for autonomous cycle counting and inventory management. Rather than explain it all here, check out Luke’s post from the floor of WMC26:

WAIT A MINUTE

While our VR tele-operated humanoid is certainly very cool, you might ask yourself: ‘Hang on. That looks cumbersome. Why not just send in a fully autonomous robot to do those difficult jobs?”

Good question. But there’s a gap between perception and reality when it comes to humanoids and their capabilities. Before a robot of any kind can be deployed for a truly autonomous task, it needs to be programmed and trained. This involves machine vision, machine learning, simulation – and much more. But the actions Joel is taking in the video above could actually be used to train that humanoid for a specific task. Here’s Luke once again:

“Imagine you have your most highly trained technician performing a task. The system can collect visual and motion and haptic data, which we can then put into a reinforcement learning algorithm via simulation and then deploy that skill or policy,” he says. In other words, what Joel is doing could be used to teach that robot to one day carry out those functions entirely on its own.

“Everyone sees humanoids through sci-fi and other mediums and expects them to be autonomous. And while that is the end goal here, we’re showing what we think is a critical, critical piece in that whole puzzle.”

The InDro demo has been drawing huge crowds throughout the show – and those in attendance fully understand the significance of what we’re showing, along with how EP5G is a critical enabler in settings where security and speed count.

Below: The Ericsson/InDro/Cypher Robotics display grabs attention at WMC26, followed by the Cypher Robotics Captis system.

INDRO’S TAKE

We love big shows, and take pleasure not only in showcasing our own innovations, but seeing all the amazing things that others from around the world are working on. WMC26 is a huge show, and we’re still processing everything we’ve seen – and will likely be exploring other innovative technologies which caught our attention that might push InDro’s offerings even further along that cutting edge.

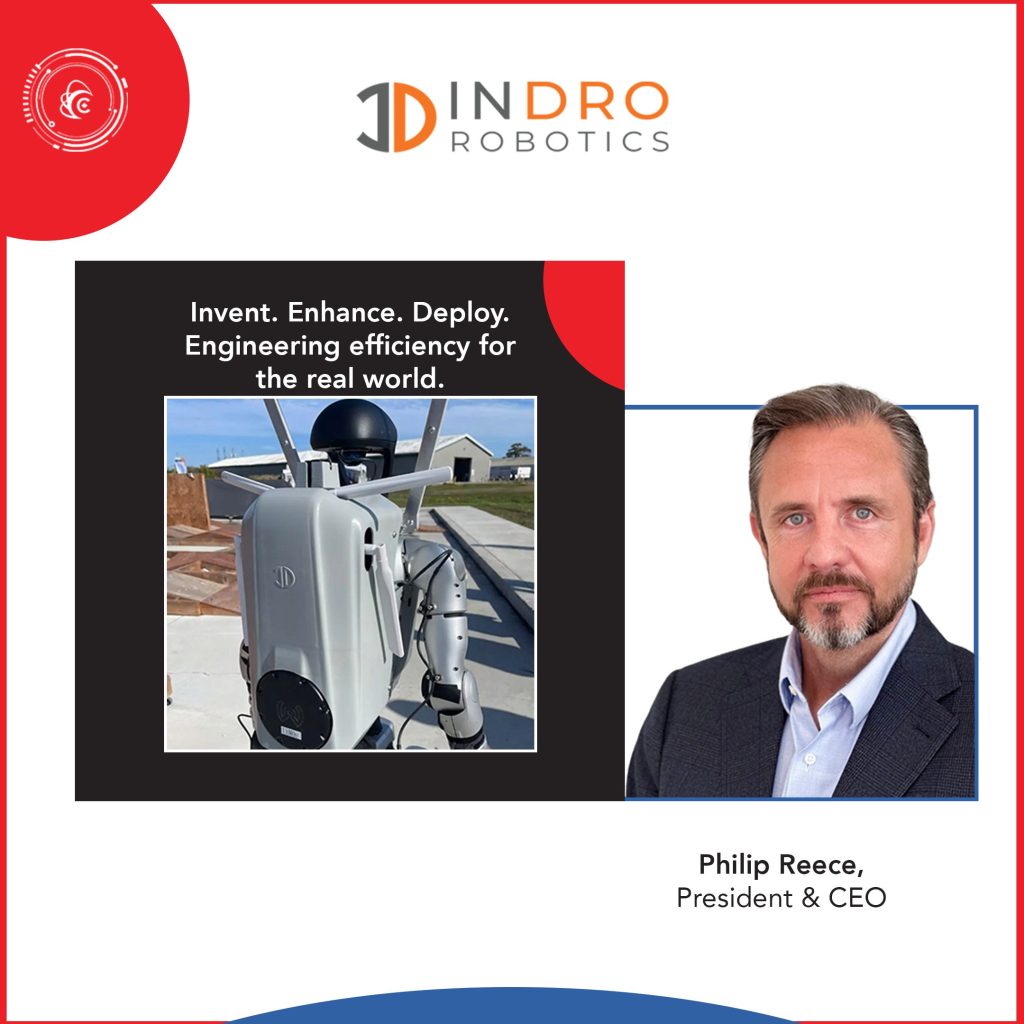

“We’re pleased with the feedback we’ve received on our VR humanoid project,” says InDro Founder and CEO Philip Reece. “We’re grateful to Ericsson for once again choosing InDro – as well as Cypher Robotics – to help potential clients visualise the incredible power of private 5G networks and the kinds of solutions they enable.”

Luke is planning a full video of his trip – including many of the cool things he saw at the show, as well as a glimpse of Barcelona. Keep an eye out for that on LinkedIn!