A Security Robot With Superpowers for $50k: Meet Prowler

By Scott Simmie

It wasn’t long ago that purchasing a reliable, robust robot for routine inspection and security patrols could easily cost you $200,000. That was obviously a fair chunk of change – and a pretty substantial barrier to entry for many companies.

InDro’s new Prowler changes the game. Capable of either remote teleoperation or fully autonomous, repeatable missions, Prowler’s wheeled quadruped platform can go just about anywhere: Up and down stairs, over obstacles – it can even clamber over low fences. With 360° high-def video and an ultra-wide LiDAR (360° x 90°), Prowler spots everything in (and even behind) its path.

“Prowler has extremely dynamic terrain traversal capabilities and it’s outfitted to be both tele-operated and also run autonomous missions,” explains Luke Corbeth, InDro’s Head of R&D Sales. “It captures photos, video, can conduct two-way audio – and perform many other functions. So it’s suited to a wide variety of verticals.”

Think construction sites or factory floors. Museums or shopping malls. Truly, Prowler is suitable for pretty much any situation where you might want a 24/7 security guard keeping a close watch on things,

Below: The InDro Prowler, a highly modified wheeled quadruped purpose-built for security and monitoring purposes.

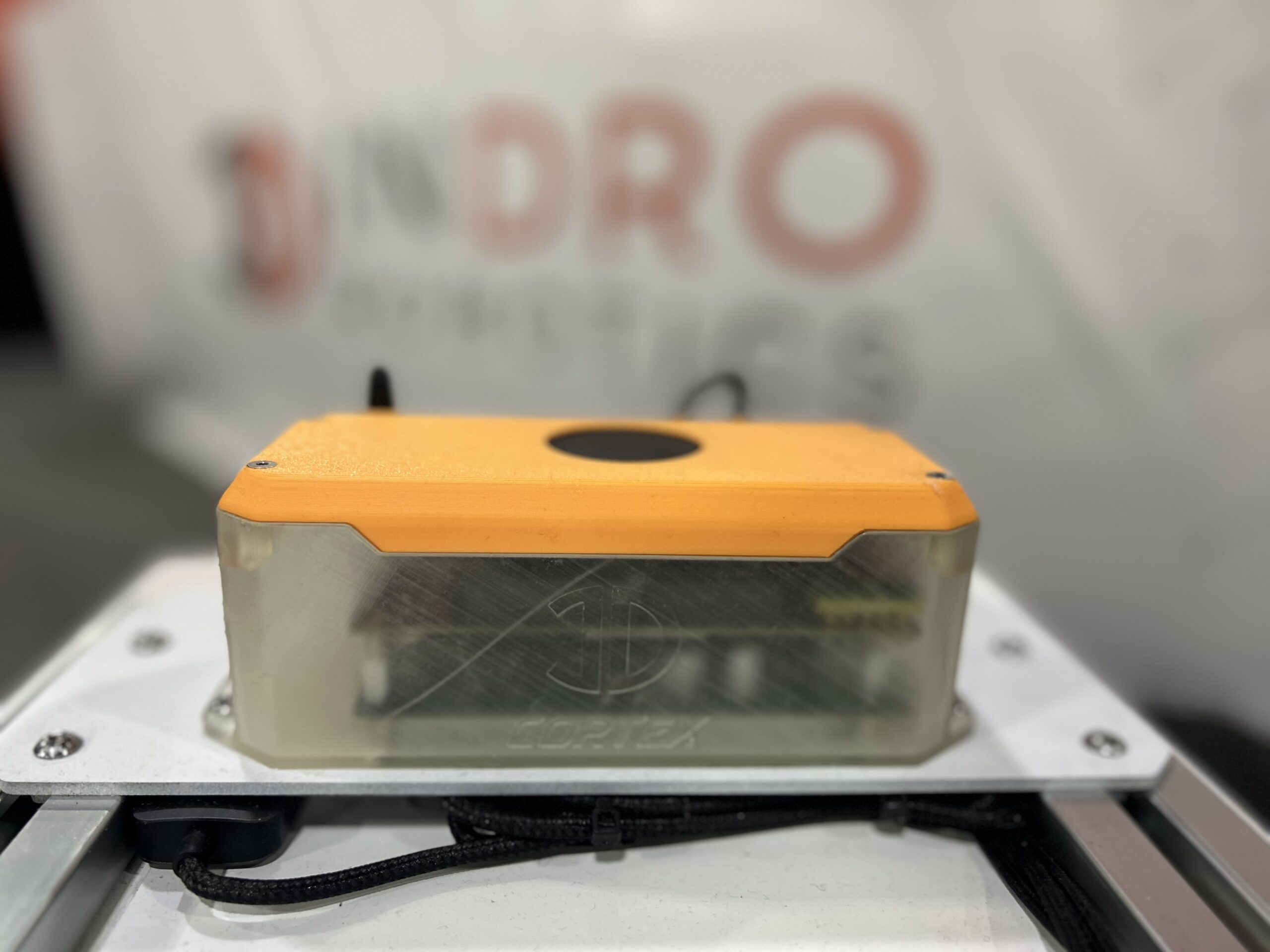

POWERED BY CORTEX

The platform and sensors are one thing. But what really gives Prowler the edge is our Cortex brain-box. The InDro device contains very powerful compute and AI capabilities, and allows for the seamless integration of additional sensors, including power distribution. Contained within our InDro Backpack, Cortex comes with our InDro Controller interface pre-loaded, 5G and 4G connectivity, as well as WiFi 6.

That means Prowler can be remotely tele-operated from pretty much anywhere. A human in the loop can monitor and control Prowler’s missions, seeing all data (including realtime video and LiDAR data) with imperceptible lag. InDro Autonomy, our powerful software stack that enables everything from pre-programmed to SLAM missions, can be added on as an option. Prowler comes ready for wireless charging, and can snug up at its home base to be ready for the next mission. And if a client wants to add additional sensors, it’s a snap.

“Absolutely. This has incredible functionality out-of-the-box, but we don’t want the road to stop there,” says Corbeth. “So we still provide the development tools that our clients are accustomed to receiving from us. But the amount of functionality that comes with Prowler is really what makes this an intriguing solution.”

OPTIONS FOR ANY USE-CASE

Prowler comes with ultra-wide hemispherical LiDAR, a top-mounted 360° camera (with seamless stitching), a forward-facing HD camera, and two-way audio for communicating with anyone it encounters. Prefer a Point-Tilt-Zoom camera or thermal option? No problem. Prowler can be configured in multiple ways, depending on your use-case. We can even pop on a powerful spotlight.

And while Prowler is already highly capable, we plan to add additional features in future that leverage its powerful AI and Machine Vision capabilities.

“Think person detection, animal detection, various other features that turn what the robot is seeing into actionable intelligence – and even actions as well,” says Corbeth. “So down the road, Prowler could send text messages to security teams, perhaps notifying local authorities, things of that nature.”

Weighing just 20 kilograms, Prowler can take on additional eight kilos in payload. And when it’s on a flat surface, this robot zips along at 2.5 metres/second (nine kilometres/hour) on missions that can last as long as 2.5 hours before returning to self-charge. Whether it’s monitoring a critical asset, doing routine security and perimeter runs, Prowler is a robust, powerful and affordable solution. You can find full specs on our package and options here.

Below: This video gives you an idea of the kind of terrain Prowler can tackle.

INDRO’S TAKE

This robot contains multiple InDro innovations, including our new and powerful Cortex, as well as InDro Controller, which makes tele-operation (and autonomous missions, with the optional InDro Autonomy software) a breeze. A lot of engineering has gone into these products, and they’ve been designed to work together. Deployments of Prowler are now underway, and we’re taking additional orders.

“Prowler fills a void in the marketplace,” says InDro Robotics Founder and CEO Philip Reece. “I’m not aware of any inspection robot with these capabilities at this price point – other than Prowler. Once again, the InDro R&D engineering team has created a groundbreaking solution suited to multiple use-cases, with the option to further customise for client needs. Prowler means business – and in more than one way.”

Want to continue the conversation or arrange for a demo? Contact Luke Corbeth here.