Draganfly sells, donates drones for use in Ukraine

By Scott Simmie

The use of non-military drones in Ukraine has jumped significantly since the Russian invasion began. Consumer products, particularly DJI drones, have been widely used by both sides in the war for situational awareness and identifying combatant positions. They’ve also been used extensively by journalists to help convey the scale of the devastation, particularly the destruction of civilian targets.

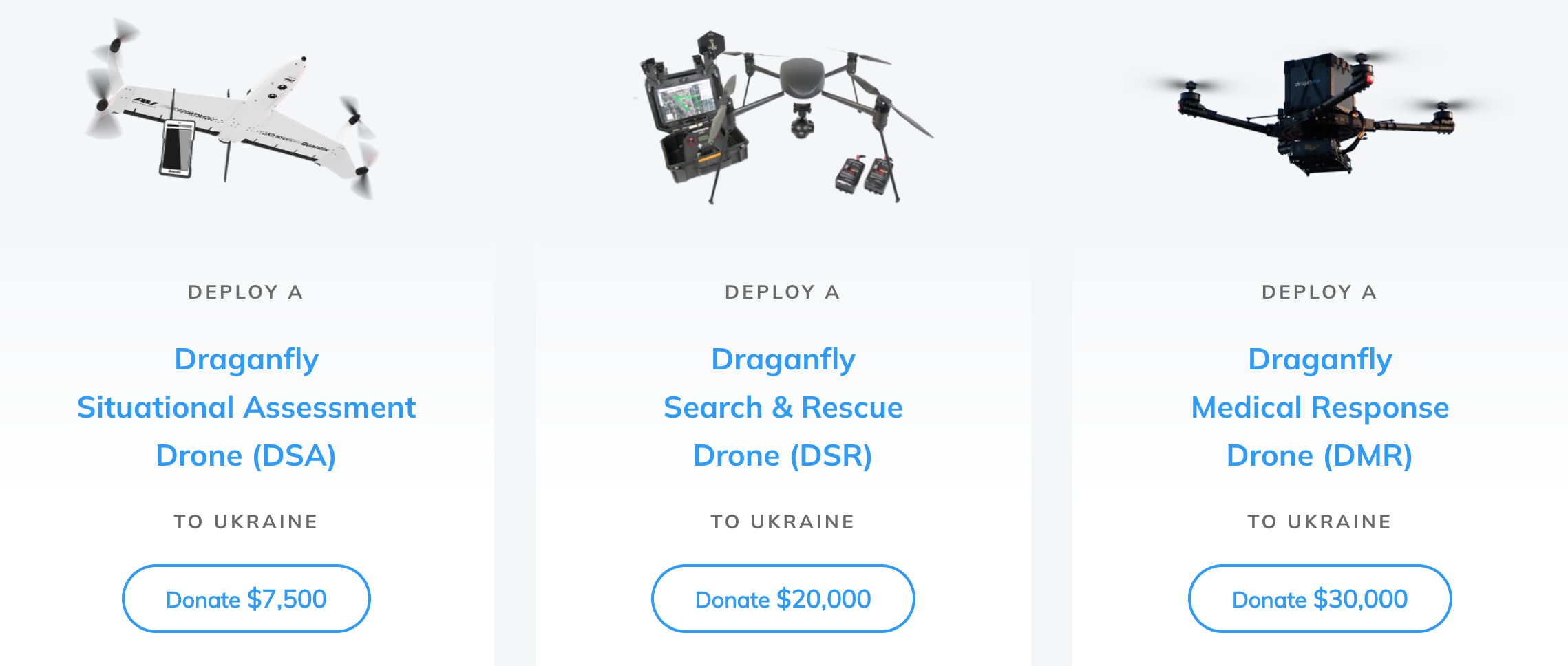

Now, North American drone manufacturer Draganfly has announced it will be sending 10 drones for use by Ukrainian forces. The drones – five Medical Response drones and five for Search and Rescue – have been purchased by a third party as a donation to the non-profit relief agency Revived Soldiers Ukraine. They are part of an initial order (subject to conditions) of up to 200 units destined for the conflict zone.

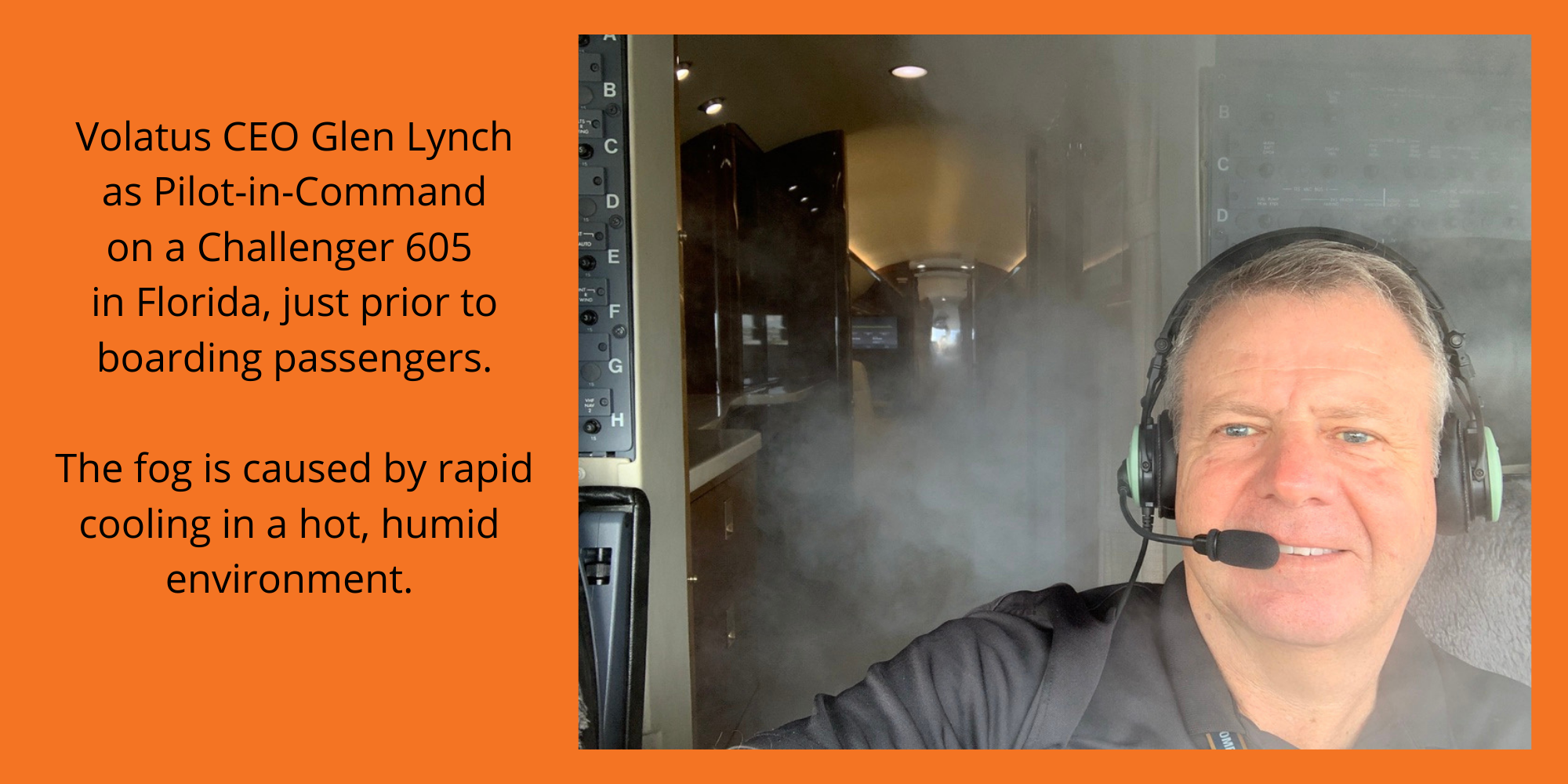

We wanted to learn more about the drones and how they’ll be used, so we sat down virtually with the CEO of Draganfly, Cameron Chell.

Before there was DJI in Shenzhen, there was Draganfly in Saskatoon, Saskatchewan (Canada). Initially founded by Zenon and Christine Dragan in 1998, the company released its first commercialized quadrotor the following year. In 2001, it released the first multi-rotor UAV with an integrated camera system.

It wasn’t long before some early adopters in law enforcement started embracing the utility of drones, using them to help document and clear accident scenes and for Search and Rescue operations.

In fact, in 2013 a FLIR-equipped Draganfly drone helped locate someone who had sustained a head injury in an auto accident and wandered away in freezing temperatures, suffering severe hypothermia. It’s credited as the first drone rescue to save a human life. In fact, that drone now resides in the Smithsonian National Air and Space museum. The case was written about here.

In July of 2015, Draganfly was acquired by a US technology firm, which is how Chell came into the picture. He says the company’s connection with First Responders has only grown – and is very much part of Draganfly’s identity.

“Draganfly has sold more than 9000 drones or drone systems to public safety,” he says. “We have a strong history of being of service, or trying to be of service, to the First Responder community. That’s a big piece of culture in the organization.”

And that’s why, he says, the shipment of drones to Ukraine is a good fit.

Drones for Ukraine

The drones were actually purchased by channel partner Coldchain Delivery Systems which specializes in packaging for temperature-sensitive products with an emphasis on medical supplies. Coldchain also has a $750,000 contract with Draganfly for a multi-phase project that could ultimately bring 9-1-1 dispatched drone medical deliveries to the entire state of Texas.

Cold Chain wanted these drones purchased for Revived Soldiers Ukraine, a non-profit agency playing a significant role in assisting during the conflict. (In March alone, RSU provided goods ranging from ambulances and portable X-Ray machines through to bullet-proof vests and helmets for medical personnel and civilians totalling more than $2.75M dollars.)

A total of 10 drones were purchased by Coldchain Delivery Systems for the initial order. Draganfly is selling the drones at cost, and is donating an additional three drones free of charge. Chell says the drones had to be modified to make them suitable for use in Ukraine.

“We had to change all the comms systems out,” he explains. “It’s a different LTE system, there’s a bunch of interference.”

The first drones will ship mid-April.

The Medical Response drone

Here’s a look at the medical drone, which uses Coldchain’s proprietary system to keep medical supplies at required temperatures.

The Medical Response drone has a temperature regulated payload of 35 pounds. It’s intended for shuttling critical supplies, including blood, pharmaceuticals, insulin/medicines, vaccines, water, and wound care kits.

You’ll note in the photo above that the payload is shown on top of the drone. This machine is also capable of carrying the payload beneath, with a quick-release mechanism. Dropping the cargo close to the ground and quickly resuming flight removes potential risk for those receiving the cargo (they won’t be getting close to the drone). It also extends battery life, since the drone won’t have to fully land, shut down, then re-start. Flight time is 25 minutes, with an estimated range of three+ kilometres with a 20-pound payload. Lighter payloads – and it’s anticipated some will be lighter – will have a greater range.

“We’re providing drones that are very specific for exactly what they need,” says Chell. “Some others might have an airframe, but they don’t have a temperature-managed payload – so this is very specifically built, this is mission-critical.”

Range on the first shipment will be limited to RF communication over two kilometres. But a second batch, modified for Ukraine, will utilize LTE and have solid communication over a 20-kilometre range.

And the Search and Rescue drones? They’re smaller, faster, and equipped with a thermal sensor – which could prove useful in detecting people trapped in rubble or bombed buildings. Revived Soldiers Ukraine has experienced drone operators; Draganfly will be providing virtual training for these specific drones, and is examining potentially sending trainers to Poland and even Ukraine if more drones are sent in future. (Assuming the first 10 are effective in the field, the potential is here for up to 200 drones being purchased.)

Donations

In addition to the these first drones, Chell says several shareholders contacted the company and offered to purchase drones to be donated to the cause. Seven drones have been purchased for this purpose. Chell says the interest has been so great the company now has a page up for people interested in directly purchasing drones for donation. The company says it will provide ongoing mission statistics for those donated humanitarian drones, and possibly even video of some missions.

As you can see by the price tags and builds, these are not consumer drones. The open-source, North American-made Draganfly products are purpose-built for specific tasks, and feature secure data handling.

Perhaps more important in a war zone, they cannot be tracked with an Aeroscope the way DJI products can. The Aeroscope device is capable of tracking not only DJI drones but also the location of the pilot, which – in a war zone – carries significant risks. (It’s believed that Russia has deployed Aeroscope units.)

“We don’t have system where someone else can track the pilot and track the drone,” says Chell. “These things can’t be tracked.”

(Just FYI, other drone companies have recently announced donations on the Ukraine front. We’ve seen recent announcements from Skydio and Volatus.

A personal connection

While Draganfly has a corporate tradition of working closely with First Responders, Chell reveals that a personal experience has made this mission resonate even more.

“I was at the base of the towers at 9-11 when the first plane hit,” he says.

“Not that I wasn’t a First Responder fan before that, but that weighs very prominently into my ethos or direction in wanting to give back to that community…and in humanitarian situations.”

InDro’s Take

Though we haven’t deployed to a war zone, we have flown disaster response missions. In addition, InDro Robotics has considerable experience with drone delivery. We shuttled COVID test kits from a remote, island-based community on a regular basis during the peak of the pandemic. We’ve also been involved in multiple trials and projects, delivering everything from prescription medications and simulated blood products through to Automated External Defibrillators.

We know, from that work, that even with deliberate planning there can be unexpected obstacles, such as gaps in cellular connectivity, interference, abrupt weather changes, etc. Draganfly has already anticipated some of these challenges, including RF interference, cellular dropouts, and the different LTE system.

Successful deliveries, especially when the cargo is critical, require getting the right product in the right hands at the right time. This is even more urgent and difficult in a hostile environment. Revived Soldiers Ukraine has been on the ground since day one of the conflict, and will have a good handle on both the challenges – and the needs.

We wish Draganfly and Revived Soldiers Ukraine the very best in this endeavour – and look forward to an update in the future.