JR Hammond and CAAM advocate the path toward Canada’s Advanced Air Mobility future

By Scott Simmie

The world of Advanced Air Mobility (AAM) is coming. Transformative and sustainable aircraft capable of carrying passengers and goods are being flight-tested daily by industry leaders like Joby Aviation, Archer and Wisk.

Machines like these – with fixed-wing eVTOL being the most popular design – will one day routinely shuttle goods, services and people over congested cities (Urban Air Mobility). They will also play an important role with Regional Air Mobility, offering access to communities that lack the demand or infrastructure for traditional aviation. Most designs are electric or hybrid, with an emphasis on sustainability.

This brave new aerospace world isn’t going to arrive overnight. There’s the question of certification, ensuring these aircraft meet demanding safety and other criteria. There’s also the challenge of determining how to safely integrate these machines within existing aviation airspace. Plus, there are questions around use-cases – how these technologies can be deployed in the most beneficial and efficient ways. Is an Air Taxi service better than delivering medical supplies? Might one aircraft carry out multiple roles?

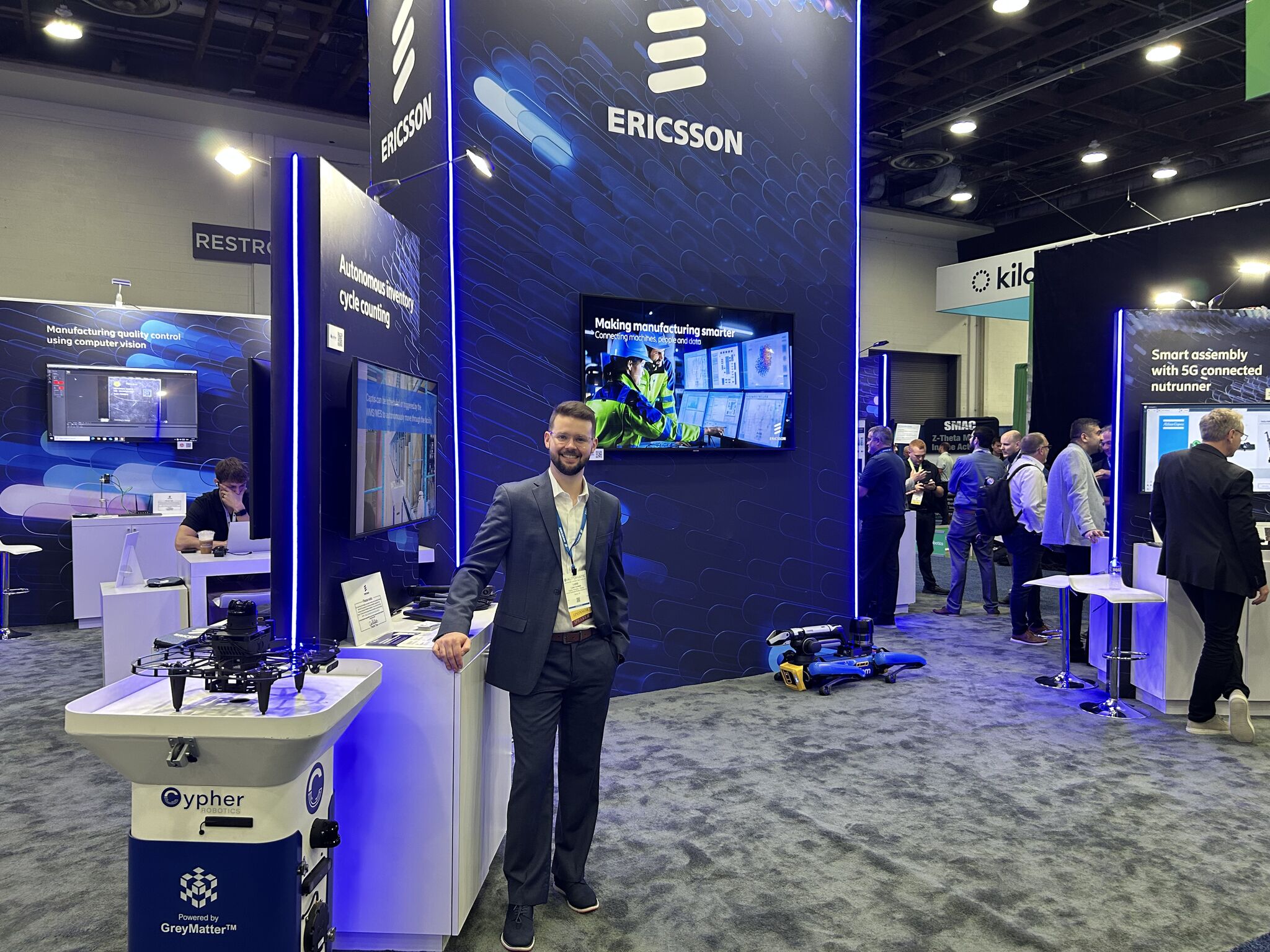

These are big questions. But there’s an organisation, Canadian Advanced Air Mobility (CAAM), working closely with companies, regulators and other partners to help chart the path and speak with a unified voice on behalf of the industry. We caught up with CAAM’s Executive Director, JR Hammond, to learn more about what it does – and why it’s so important this body exists.

Above: Wisk’s autonomous eVTOL. Below: CAAM’s JR Hammond

WHAT IS CAAM?

That was the first question we put to JR Hammond. Here’s his answer:

“Canadian Advanced Air Mobility is the national industry association here in Canada that brings together our industry, academic and government (partners) all around the momentum of trying to expedite the operations of these new AAM aircraft in the country of Canada,” he said.

Given the rapid development of these innovative aircraft, in conjunction with the push toward a more sustainable future, CAAM is arguably the right organisation at the right time: We are truly on the cusp of an inflection point in the evolution of aviation.

The roots of CAAM go back to 2018, when JR attended the Uber Elevate Summit in Los Angeles. Some 750 experts, manufacturers and regulators got together to discuss the potential of new eVTOL aircraft. A White Paper was unveiled, with the emphasis on the Air Taxi model.

Hammond wanted to get involved. There were some openings in the field, but they all seemed to require aerospace PhDs and US citizenship. JR didn’t tick any of those boxes but was passionate. He started to envision broader implications on the horizon – and the need for a national AAM organization in Canada.

And so, as an entrepreneur, he decided to create one.

JR returned from that conference and wrote up a business plan – which he pitched far and wide. One person, Eric Lefebvre (then Director of Business and Strategy Development with the National Research Council’s aerospace division) immediately understood the pitch and co-founded CAAM with Hammond. So that’s the origin story in a nutshell.

Since then, the concept of use-cases has broadened far beyond Air Taxis. And it’s that broader potential that really excites JR. He envisions moving critical medical supplies, people, and other goods and services. And not only in congested urban settings – but also serving regions and remote communities underserved by traditional aviation.

“The key language that we like to use is it’s not replacing any of our ground transportation, it’s actually complementing… especially outside of our dense urban city centres moving people, goods and services back and forth,” he says.

“What we know for sure is that Canada does not have the economic or population density to support that Air Taxi concept as our go-to-market strategy. We need to find some of those near-term cargo medical movement opportunities that have high value and high impact for go-to-market and then allow the ecosystem to expand.”

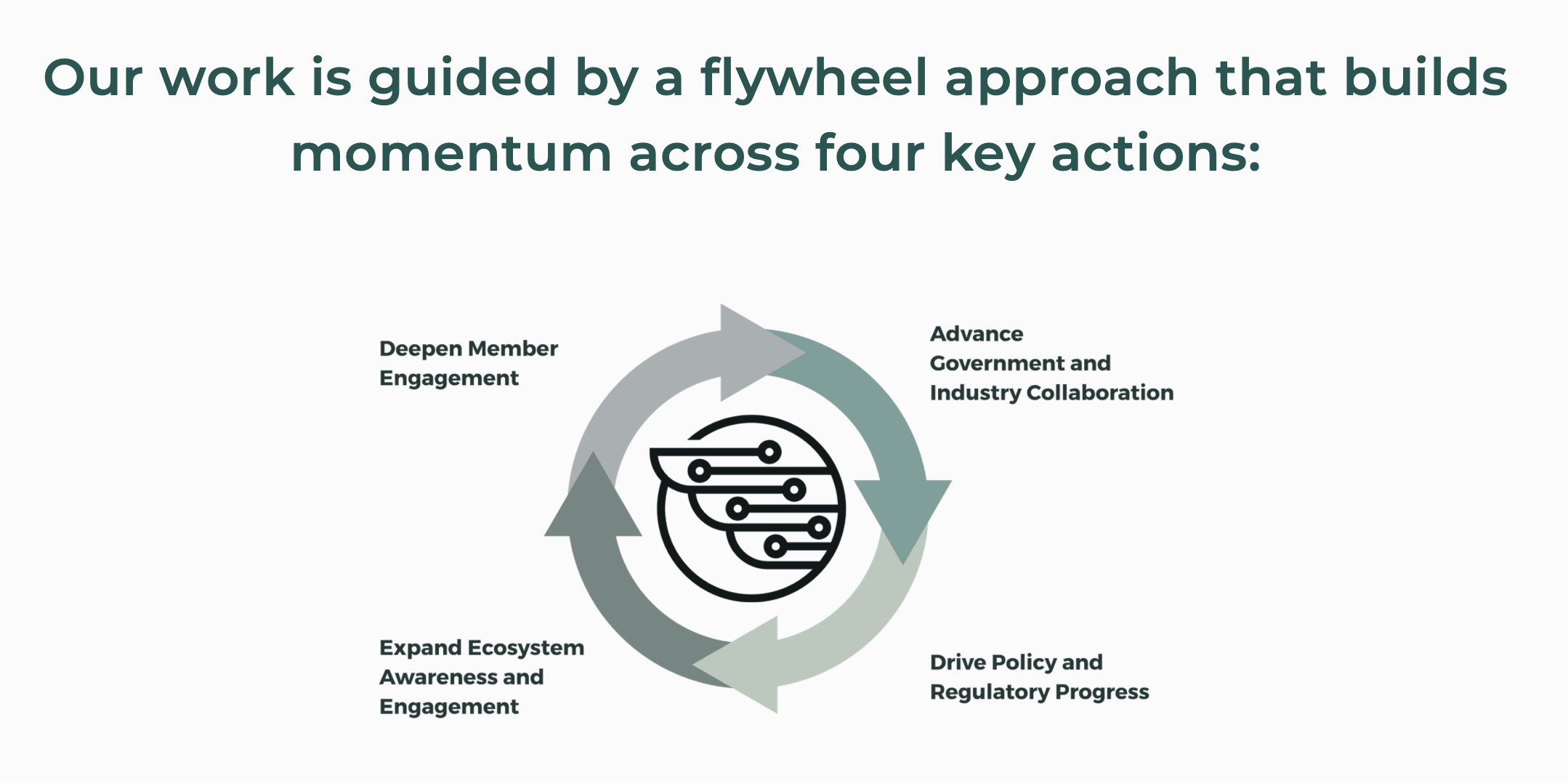

Below: A graphic from the CAAM website explains its purpose/vision

WAIT, THERE’S MORE

In addition to working closely with industry, regulators and academia, the organisation also works hard at developing connections. Early in 2025, CAAM hosted a highly successful trade mission to California, where participants were able to tour cutting-edge AAM facilities and engage with industry leaders.

“We are really leaning in to how we connect Canadian champions with some of the global leaders in Advanced Air Mobility like the OEMs of Joby, Archer and Wisk.”

Such missions, he says, serve three key purposes:

- Seeing the progress of these companies in person and making connections

- Exploring how Canadian companies can become part of the value chain

- Examining potential for bringing these OEMs into Canada

CAAM membership has expanded rapidly. And while initial members were largely in the AAM or RPAS space, traditional aviation companies have been coming on board in increasing numbers.

“A lot of conventional aviation organisations are looking to expand and be a part of this new developing Advanced Air Mobility ecosystem,” he says. “The overlap between commercial aviation and Advanced Air Mobility is actually coming closer together.”

MOVING FORWARD

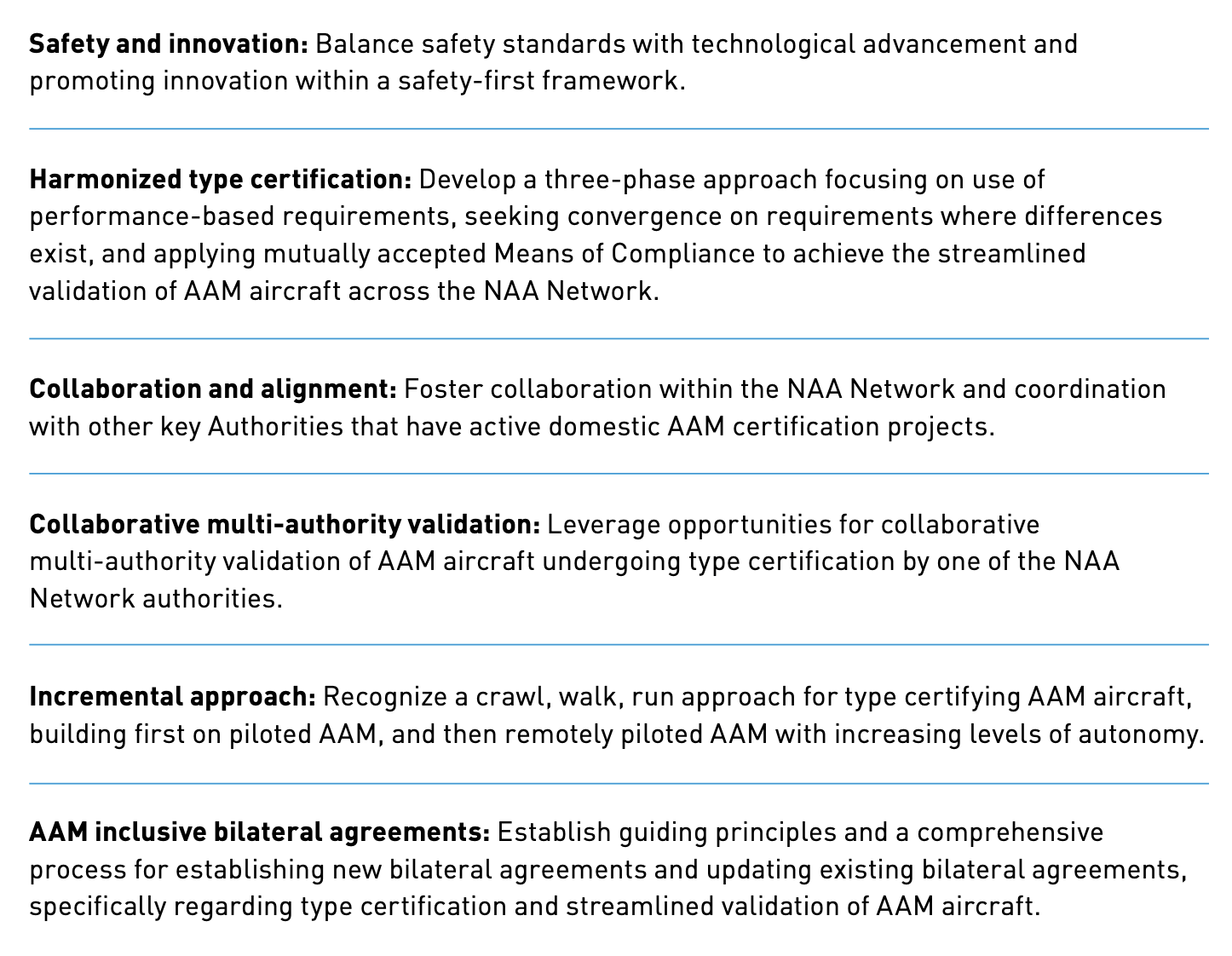

The other news, big news, is that in June an important document was released. Entitled “Roadmap for Advanced Air Mobility Aircraft Type Certification,” it’s a collaborative effort between the aviation regulatory bodies of Canada (Transport Canada), the US (FAA), New Zealand, the UK and Australia.

The roadmap’s Executive Summary explains the document “sets forth a unified and strategic approach to foster collaboration, safety assurance, technological innovation, and AAM inclusive bilateral agreements. In the face of emerging AAM technologies, including electric Vertical Take-Off and Landing (eVTOL) aircraft, the Roadmap outlines a clear path to align aircraft type certification standards, harmonize airworthiness requirements, and facilitate information sharing among network members to maximize the transferability of type certified AAM across the Network, whilst acknowledging an incremental approach to the type certification of AAM aircraft.”

JR Hammond says the document is hugely significant.

“This is something we’ve been waiting for quite a while to go public with,” he says. “We all have common interests in how these new Advanced Air Mobility aircraft will be certified…So it’s a good stick in the sand to start the progress.”

Below: Key points from the Roadmap’s Executive Summary. Image via the National Aviation Authorities Network under Creative Commons 4.0

INDRO’S TAKE

We are very excited about the coming world of AAM – and particularly about the potential for positive use-cases with Regional Air Mobility, getting critical goods and services (and people!) to regions that have existing barriers to traditional aviation. We’re impressed with the work being carried out in the US, Canada and elsewhere to bring these sustainable innovations forward.

“These are still early days, but AAM has incredible momentum and will someday transform our airspace and enhance use-cases,” says InDro Robotics Founder and CEO Philip Reece. “InDro is pleased to be a Project Partner with CAAM under JR’s leadership, and we look forward to playing a significant role in the AAM space in the future.”

In case you missed it earlier, you can download that AAM roadmap here.

You can also hear JR Hammond discuss CAAM at greater length with Scott Simmie in this InDro Sound Byte micro-podcast.