Breaking drone regulations can be expensive

Drone regulations exist for a reason. Actually, multiple reasons.

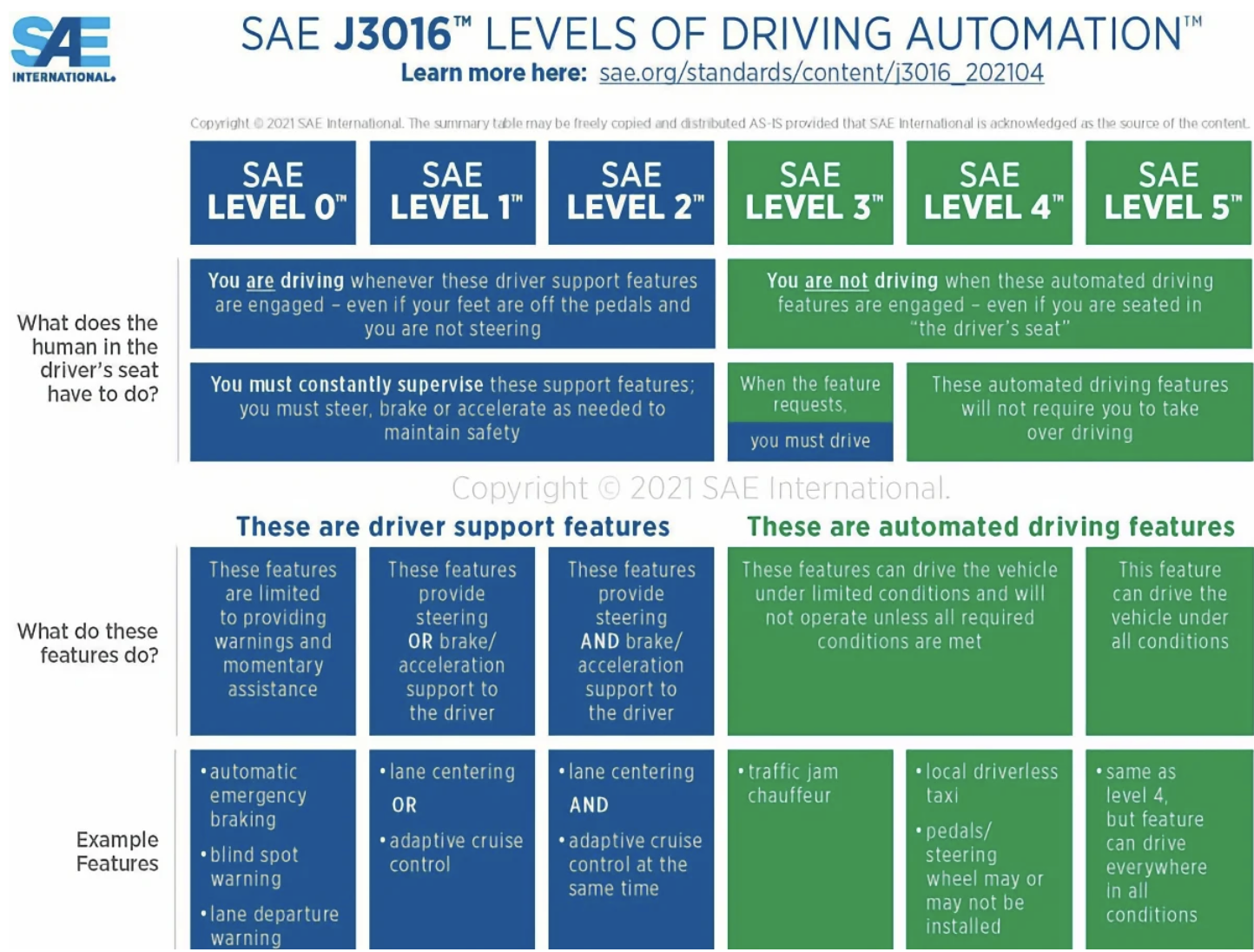

Probably the most important is to keep airspace safe and avoid any potential collisions or interference with crewed aircraft. That’s why altitude is limited to 400′ above ground level (AGL), and why flights in controlled airspace must be cleared through NAV Canada’s NAV Drone app. (If you’re a drone pilot and don’t have this app, you can get more details and links to download here.)

And, just as a reminder on that front, drones carrying out basic operations must be at least 5.6 kilometres (three nautical miles) from airports and 1.9 kilometres (one nautical mile) from heliports.

One of the other key reasons is to protect people and property on the ground. If you’re flying a drone weighing more than 250 grams and less than 25 kilograms, you’ll need to ensure that you’re separated horizontally from bystanders by at least 30 meters – though drones with an RPAS Safety Assurance declaration can fly closer in Advanced operations.

There are, of course, other rules. No flying over outdoor concerts, parades or other special events. Some of you may recall that a drone pilot paid a hefty price during the victory parade for the Toronto Raptors in 2019. The person in question flew over the event and was fined $2750 by Transport Canada. (We actually were at that parade and saw the pilot take off; he was flying a DJI Mavic Pro.)

Breaking drone rules can be expensive.

Below: A 360° shot taken during Raptors celebrations. The illegal drone flight took off about 15m from where this image was taken.

There’s a reason behind every rule

The laws that govern drones in Canada are written up in a section of the Canadian Aviation Regulations, also known as CARs. Specifically, they reside in Part IX. We recommend that everyone flying a drone in Canada – particularly drones weighing more than 250 grams – has a read through this section. It lays out the rules very clearly.

And if you break those rules? Well, there’s a price to pay. Fines for individuals include:

- up to $1,000 for flying without a drone pilot certificate

- up to $1,000 for flying unregistered or unmarked drones

- up to $1,000 for flying where you are not allowed

- up to $3,000 for putting aircraft and people at risk

So it’s worth knowing the regs, because violating them can both create risk and be very costly.

Forest fires

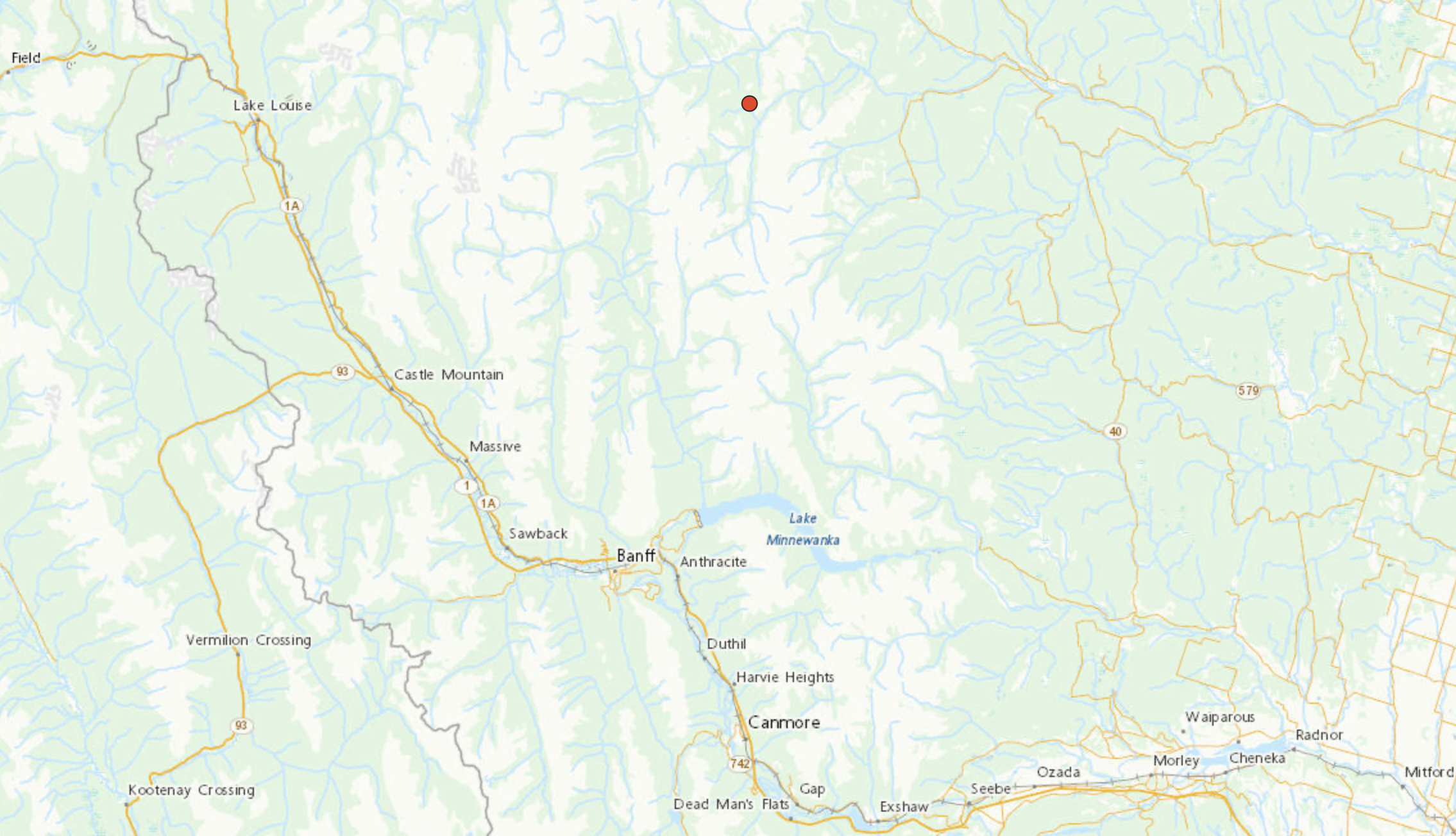

Wildfires in Canadian forests cause major problems every year. Significant resources are allocated to try to control and extinguish these fires – which often occur in remote locations. Aerial firefighting techniques are a big part of the equation, with water bombers and helicopters routinely deployed. (You can get a snapshot of the current wildfire situation in Canada with this interactive map. At the time this article was written, a significant Alberta fire – north of Banff and east of Lake Louise – was out of control. That fire started August 31 and has been burning for three and a half months.)

Helicopters are used to transport crews, and occasionally drop fuel retardant on small hotspots. Water bombers come in low to take on water from lakes and also drop that same water on fires from low altitudes so that targeting is accurate and there’s minimal dispersal of the fluid on the way to the ground.

And both of those scenarios? They mean these aircraft are often flying below 400′ AGL.

Keep your drone clear of forest fire operations

With that context, you no doubt have guessed where we’re going with this. Rules in CARs Part IX prohibit flying drones near forest fire operations. In fact, you must keep drones (and other aircraft not involved with the operations) at least five nautical miles (9.3 kilometres) away from the scene. There is also a mechanism within the Canada National Parks Act that allows for the prohibition of activities – including the banning of drone flights.

Recently, a drone pilot found out just how seriously regulators take flying drones close to a wildfire. A Canadian Press story published December 9th says that Rajwinder Singh was found guilty in an Alberta provincial court of the offence and fined $10,000.

In fact, Singh was one of four people charged for flying too close to the Chetamon wildfire in September. Four drones were also seized by authories.

InDro’s role

InDro Robotics played a role on the technology side. The company supplied drone detection equipment capable of identifying models, location and trajectory of drones in proximity of Alberta wildfires.

InDro is also involved with the Ottawa International Airport Authority’s ongoing Drone Detection Pilot Project at the Ottawa International Airport. Early in 2021, during the convoy blockade that took place in Ottawa, that project detected a very high number of illegal drone flights taking place over sensitive areas in the capital’s downtown core.

In fact, a sister company of InDro Robotics – Bravo Zulu Secure – specializes in drone detection and mitigation systems. InDro Founder and CEO Philip Reece is the Chief Technical Officer of Bravo Zulu. Here, he explains some of the company’s proprietary systems:

InDro’s Take

We’ve been in this business long enough to remember the early days. The drone space was often called The Wild West, because many people were either unaware of regulations or chose to willfully ignore them. This was particularly true of rogue pilots, usually recreational operators, who would carry out reckless flights. Those flights often (and rightfully) received negative press coverage and caused regulators to take an even more cautious, incremental approach with opening up the skies. Understandable.

Since then, the drone community has done a great job of educating and even policing itself. Flights like the four that took place near that Alberta wildfire are now, fortunately, very rare.

But, as we’ve seen here, they still happen. Not only is it wise for drone operators to become fully familiar with Part IX of CARs, but also to be aware that hefty fines can and will be imposed on those who violate the law. It’s also worth remembering, regardless of location, that the technology exists to detect these flights, along with the location of the operator.

Thankfully, the vast majority of drone pilots know the regulations – and abide by them.