InDro Robotics hits multiple milestones in 2023

By Scott Simmie

Happy New Year!

We hope you’ve enjoyed the holiday season and that 2024 will be a good year for you.

While looking ahead, we at InDro Robotics always take this opportunity to also look back; to reflect on the year that was. In particular, we like to focus on what we accomplished. And 2023, for multiple reasons, was a very big year for us.

We designed and built sophisticated devices for some of the biggest technology companies in the world. (We really wish we could share that news, but under NDA we cannot. We can tell you that our last shipment, which took place in December, required two large transport trucks.)

And while that was certainly a highlight, there were many, many others. Let’s kick off our Year in Review with a device we’re very proud of, the InDro Backpack.

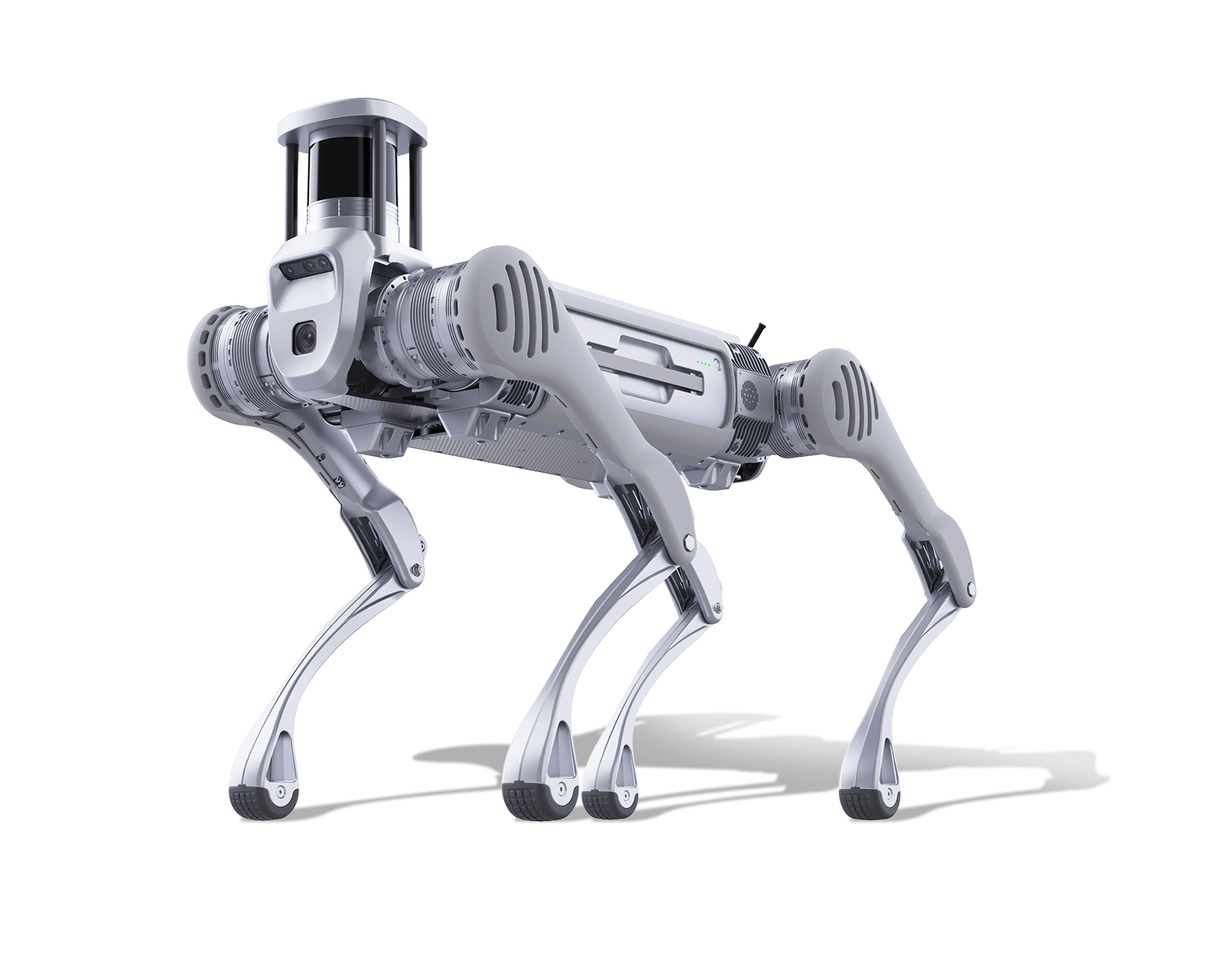

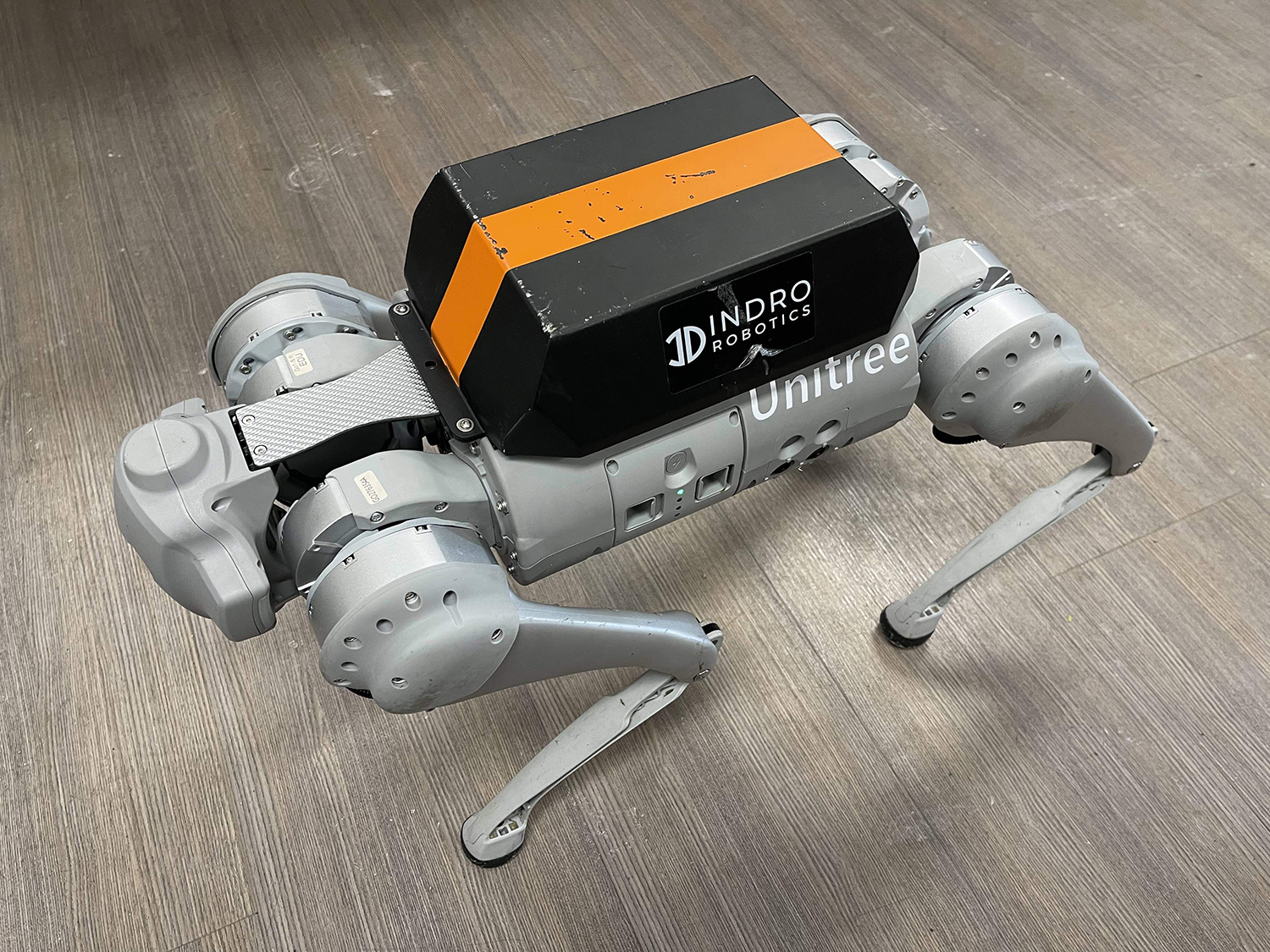

INDRO BACKPACK

Designed for Unitree quadrupeds (InDro is a North American distributor), the Backpack mounts onto the Unitree GO1 EDU, GO2, B1 and B2 robots. And it vastly expands their capabilities.

First off, the Backpack enables data-dense teleoperations over 5G with virtually zero lag. Using InDro’s dashboard and intuitive control system, you can remotely operate the Unitree robots from anywhere there’s a cellular connection at both ends.

But that’s not all. The Backpack contains the Robot Operating System (ROS) software libraries, along with multiple USB slots. This makes customising these robots with additional sensors a breeze, saving a lot of engineering time. The backpack also contains a pinhole camera, offering the operator a First Person View of operations. The customisable dashboard allows the user to see data flowing in from all sensors and overall system health.

This device, inspired by InDro Commander (which does the same thing for wheeled and tracked platforms), is 100 per cent an InDro innovation from the ground up. Take a look:

YOW DRONE DETECTION

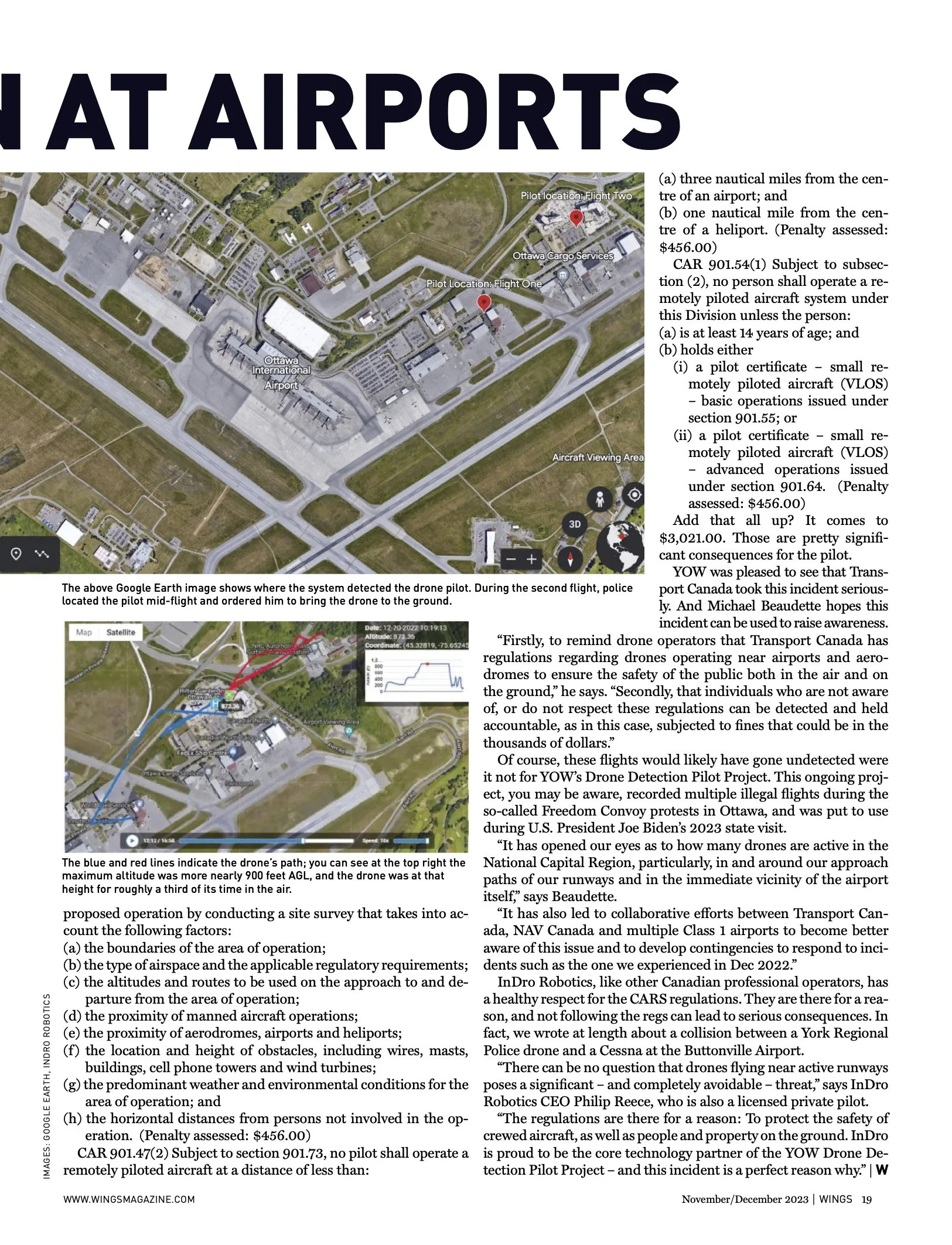

You may be familiar with the Ottawa International Airport’s Drone Detection Pilot Project. InDro Robotics is the core technology provider of the system, which monitors drone traffic not only immediately surrounding YOW, but from as far as 40 kilometres away.

In 2023, in addition to its regular monitoring, the system was involved with two high-profile events. First, the system detected someone flying a drone right at the airport, and in the vicinity of both a helicopter and an active runway. (This happened in December of 2022, but we could not publicly report on it until Transport Canada completed its investigation.)

The system located not only the drone (including its make and model), but the pilot as well. Police were dispatched, and Transport Canada ultimately imposed fines totalling $3021 for multiple violations of the CARs regulations. You can read our coverage here, as well as this take from Don Drones On.

The second significant event involved the visit to Canada by US President Joe Biden. Advance teams from the Secret Service and Air Force One visited YOW prior to the trip – and one of the first questions they had was whether YOW had a drone detection system in place. The system was carefully monitored during the arrival and departure of Air Force One. Thankfully, there were no incursions. Our story was picked up by sUAS News – and the CBC also covered the story:

FAA AND INDRO

Early this year, InDro Robotics received what we believe to be a first for a Canadian company: A US Federal Aviation Administration waiver permitting BVLOS flights for solar farm inspections in the United States.

Like our ground robots, our aerial robots are equipped for 5G teleoperation, so distance is no barrier. InDro ships the drone to the location, instructs the recipient on how to power on and visually observe – and we carry out the flight. Since receiving this waiver, we have carried out highly successful solar farm inspections in the US.

Here’s a look at how the system works.

MARATHON DRONE FLIGHTS

This headline has two meanings. The first is that we were flying sub-250 gram drones continuously for several hours in a relay-like fashion. When the batteries on one drone started to drain, a second was put in the air. So it was kind of a marathon in terms of continuous drone operation.

But the bigger meaning relates to the annual Montreal Marathon. InDro Robotics was called in to take part in a research trial. It was known from previous marathons that there were specific locations where runners tended to encounter difficulties and even collapse. But with no surveillance from above, it took time both to identify a runner in distress and also pinpoint their precise location.

The drones we put in the air provided an uninterrupted live feed to a tent where they were continuously watched on large-screen monitors. Sure enough, the live video did help detect and locate runners who needed assistance. You can find our story here. It was also picked up by COPA – the Canadian Owners and Pilots Association. Their coverage is here.

Below: Our crew kept sub-250 gram drones in the air for hours at the Montreal Marathon.

BIG CLIENT, COOL ROBOT

A major international company (a household name, truly), asked us to build a robot for them. Specifically, a research robot they could deploy in crowds of people. Engineering lead Arron Griffiths explains:

“The client wants to use Vision SLAM (Simultaneous Localisation and Mapping) to essentially detect humans and pathways through chaotic environments,” he says.

“Think malls, shopping centres…where humans are mingling to navigate around. And there’s no really defined path, the robot must organically move around people. Yes, you’d have an overall predetermined path with a desired destination, but once the chaos of humans comes in the robot would safely meander its way through crowds.”

The client was so pleased with the result they agreed to allow us to show the finished product. You’ll note the height – which was necessary so that sensors could be placed at roughly eye-level of the humans it avoids. You can find more technical details about the project here.

This is a perfect example of one of InDro’s key functions: A client comes to us with an idea for a product that has not yet been created. In deep consultation – and with plenty of updates along the way – InDro designs, builds, tests and ultimately delivers the finished product.

Below: The robot navigates crowds along a boardwalk

DARTT OPENS!

June saw the opening of the new Drone and Advanced Robot Training and Testing centre, or DARTT, at Area X.O in Ottawa. The state-of-the-art facility was funded by the Government of Canada through the Federal Economic Development Agency for Southern Ontario (FedDev Ontario) and in-kind industry contributions from InDro Robotics.

DARTT is the first facility of its kind in Canada, built from the ground up for the testing of ground robots (wheeled, tracked, quadrupeds and bipeds) and drones. The robot testing area consists of multiple sets of obstacles build to specific criteria set out by the National Institute of Standards and Technology (NIST). Robots can be tested on various uneven surfaces, through varying aggregates (sand, gravel, etc.) and through water. There’s even an incline ramp that can be adjusted to test the ability of robots to climb.

InDro operates the facility, helping to test the limits of robots – and their operators. DARTT also contains a large netted enclosure for testing new drone technologies that might otherwise require a Special Flight Operations Certificate from Transport Canada. (Plus, the top of that large enclosure can serve as a safety net when testing drone parachutes.)

InDro offers flight reviews and advanced and specialised drone and robot training at the site. We are also planning to launch a series of Micro-Credential courses in 2024, allowing for short-duration, intensive training in specific drone technology skills.

You’ll find a more thorough story about DARTT here, as well as a video below.

INDRO TAPPED FOR SPECIALIZED DRONE MISSIONS

It’s not uncommon for InDro to be approached to participate in research trials involving drones (the Montreal Marathon is but one example), but also in emergency situations. This year saw both.

When wildfires threatened many regions in British Columbia, the City of Kelowna contacted InDro. Might we be able to assist in mapping some of the damage? And could we use thermal sensors to detect hotspots that might be smouldering beneath a landfill?

We jumped into action quickly, selecting our partners at Spexi Geospatial to carry out the flights using their special software. That system allows the pilot to select an hexagonal area of interest (a “Spexigon”), and the drone will take off and carry out the mission autonomously. It will ensure that photos are taken at the correct intervals and a consistent altitude so the back-end stitching goes seamlessly. Plus, a pilot can fly multiple Spexigons in a single mission, allowing all of that data to produce imagery at scale. Resolution is very high, at 3 cm/pixel.

During one 2023 mission, “over 10,000 acres of imagery was captured in three days,” says Spexi COO Alec Wilson.

“We’ve made it super simple to get images in and out at scale… And we’re super-excited to be able to start building bigger and better platforms for the drone industry.”

InDro has invested in Spexi Geospatial, as we can see the value of automated image capture at scale. Already, Spexigon has carried out trials where it has captured two entire BC cities in a matter of days, with much bigger projects on the horizon.

You can read more about our work in Kelowna here, and more about Spexi here.

Below: Spexi COO Alec Wilson speaking in Ottawa at the Aerial Evolution Association of Canada’s annual conference.

URBAN WIND TUNNELS

InDro has previously teamed up with the National Research Council of Canada on research projects. For example, we’ve pushed several drones to their limits in the NRC’s wind tunnel in Ottawa to compare the ability of drones to withstand high winds when compared with the manufacturer’s specifications.

This year, the NRC asked if we could help with an even more challenging project: Measuring urban wind tunnels.

The NRC is interested in how drones react in urban settings, where windspeeds can be greatly influenced by architecture. Tall buildings in close proximity can turn a stiff breeze into something approaching a gale, along with producing wind shear, strong vortices and other invisible threats to drone flight.

But just because you can’t see these unusual air patterns doesn’t mean you can’t measure them. In conjunction with the NRC, we outfitted an InDro drone with two small, highly sensitive anemometers that measure windspeed. They were mounted on a wishbone-like device, allowing the sensors to be clear of prop-wash for more accurate measurement. One anemometer was mounted vertically, while the other was angled horizontally. This allows researchers to measure the precise angle of the wind, including localised updrafts and other anomalies.

Chief Pilot Eric Saczuk was the Pilot-in-Command on these challenging operations, which took place over multiple days in Montreal. The data will not only help researchers understand and predict the impact of urban wind tunnels, but may also result in useful guidelines for companies flying drones in urban environments.

(We also carried out some research flights in Vancouver Harbour, flying through a specific corridor near congested airspace, all while measuring the quality of 5G signals throughout the flight.)

You can read about the NRC wind tunnel research in greater detail here. The image below shows the drone with both anemometers attached.

INDRO “FORGES” AHEAD

One of the major highlights of the year involves InDro Robotics now offering a plethora of new fabrication and design services. In a strategic partnership with Invest Ottawa, what was known as the Bayview Yards Prototyping Lab is now called InDro Forge and under the management of InDro Robotics.

The facility is equipped with a wide array of additive and subtractive manufacturing capabilities, including:

- CNC machining

- Silicone and urethane casting

- Multi-element 3D printing (including metal)

- Electronics and Printed Circuit Board fabrication and analysis

There’s even a water jet table capable of cutting through several inches of steel.

The facility offers services ranging from one-off prototypes to design and full product development. If you can dream it; InDro Forge can build it.

“Some of our other clients come to us where they have an early prototype that they’ve cobbled together. It tells them that their idea is possible but it’s not a product yet,” says InDro Forge lead Joel Koscielski. “So we’ll help them turn that into a more refined version of itself. We might do one of those, we might do five – even 25.”

Projects can be big – or small.

“Sometimes it’s just that extra bit of capacity – they themselves have never had to make a sheet metal box that looks good,” adds Koscielski.

In addition to serving clients in need of prototypes, Minimum Viable Products and limited production runs, InDro also now has the ability to fabricate in virtually any material for our own projects – which will shorten timelines.

Below: A powerful water jet table at InDro Forge. It uses high-pressure water mixed with an exceedingly fine aggregate to cut through pretty much anything with precision

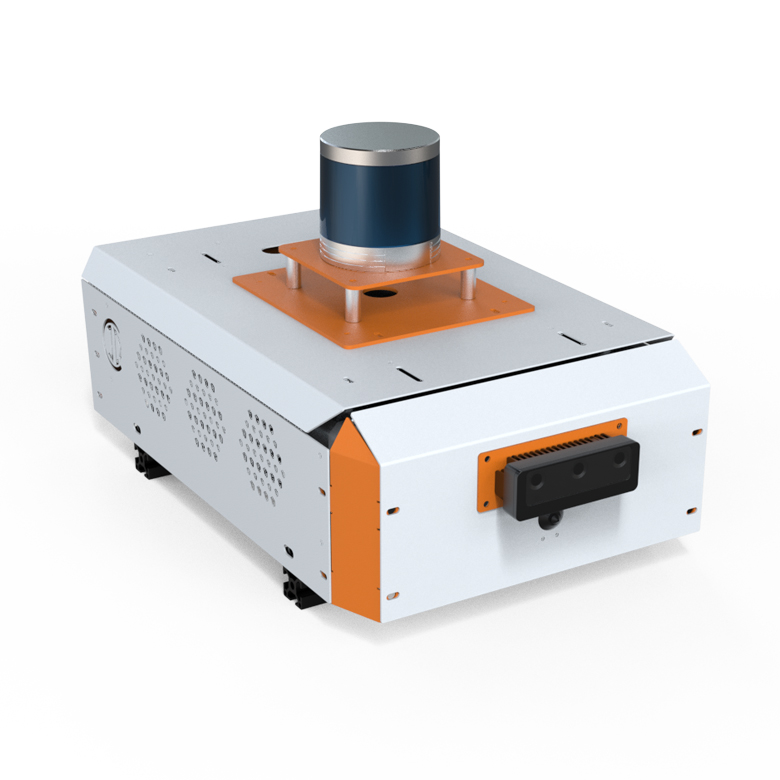

STREET SMART ROBOT

Another of our 2023 milestones was the design and fabrication of what we call the Street Smart Robot. Its purpose is to ensure safe winter cycling.

Canadian cyclists are a hardy bunch, and many of them don’t let the winter season stop them from utilizing bike lanes. But with winter comes hazards – ice, potholes, debris – that can pose a threat to a safe cycling experience. The Street Smart Robot (SSR) has been built to drive through bike lanes autonomously – while scanning for the above hazards and more. Once it detects an anomaly, City of Ottawa (where it’s being tested) maintenance crews will be notified.

“The idea behind the robot is we want to prolong the use of bike lanes in Ottawa, but also ensure the safety of bike lanes in Ottawa,” explains Indro Robotics Account Executive Luke Corbeth.

“There’s really two parts to this: The first is a machine vision element to see if conditions are good enough for biking – no ice, not too many leaves, etc. On the safety side, the Street Smart Robot is more concerned with detecting things like potholes and cracks. And the idea is if you’re able to identify those things, the right resources can be deployed faster and more efficiently to solve the problem in a timely manner.”

PARTNERSHIP

The SSR came about thanks to a research and development fund called the Wintertech Development Program. Its purpose is to support “Ontario small and medium enterprises (SMEs) and their partners to validate, test, prototype, and demonstrate new products and technologies designed to meet the unique demands of winter weather conditions.” InDro matched the funds via the work it carried out.

Wintertech is run by OVIN, the Ontario Vehicle Innovation Network. That’s a province of Ontario initiative which “capitalizes on the economic potential of advanced automotive technologies and smart mobility solutions such as connected and autonomous vehicles (CAVs), and electric and low-carbon vehicle technologies, while enabling the province’s transportation and infrastructure networks to plan for and adapt to this evolution.”

There’s a *lot* of technology packed into the SSR, including sensors and compute power to ensure both obstacle avoidance and AI/Machine Vision recognition of potential threats. Technology onboard includes:

- Front and rear-facing depth cameras that perceive in 3D

- Two 2D LiDAR units for obstacle avoidance and safety

- Two 3D LiDAR sensors for Simultaneous Localization and Mapping (SLAM)

- GPS and Inertial Measurement Unit

- Range finder to detect the height and position of hazards like tree branches on the path

There’s a lot more to this machine, and you can find all the details here. InDro will be testing the IP67 robot in early 2024, once there’s plenty of snow and ice in Ottawa.

Below: A brief video highlights the Street Smart Robot, unveiled at TCXpo in September.

TCXpo

September brought the second annual TCXpo event to Area X.O. It’s Canada’s premiere showcase of Smart Mobility, with leading technology companies from across the country demonstrating their products. This year saw more than 75 firms take part with active demos, static displays, and plenty of learning sessions.

The event was sponsored by Transport Canada (that’s the “TC” in “TCXpo”), along with Invest Ottawa and Innovation, Science and Economic Development Canada (ISED).

InDro was kept busy with running demos of the new DARTT facility, putting ground robots through demanding obstacle courses and flying drones inside the netted enclosures. There were plenty of other cool demonstrations and displays, ranging from a self-driving tractor through to a remotely operated hang-glider intended for heavy cargo deliveries.

As Michael Tremblay, who was then President and CEO of Invest Ottawa, Area X.O and Bayview Yards, put it: “We’ve got incredible capability right across the country.”

It’s a great event, and one that truly highlights that the era of Smart Mobility is firmly en route. Kudos to the organizers for putting on such a great show.

Below: A few images from the 2023 TCXpo, including the InDro Robotics Ottawa team behind some of our many robots. That’s followed by a video highlighting the event.

WAIT, THERE’S MORE

There’s actually a *lot* more, but we know you’ve got other things to do in 2024. So just a final few highlights:

- InDro forged a new partnership (and product) in conjunction with Tallysman on a super-accurate GNSS solution for ground robots

- We refined our popular InDro Commander, an InDro innovation that enables remote teleoperation and the rapid integration of sensors. A smaller Commander is en route soon!

- We welcomed – and are modifying – new robots from Unitree and AgileX (InDro distributes products from both companies)

- We have a new Robot Operating System (ROS) drone (more to come on that soon)

- We’ve been working hard on a new automated inventory management system, designed to simplify warehouse supply chain management

INDRO ON THE ROAD

Finally, InDro attended a number of major conferences and exhibitions throughout the year. We displayed and demonstrated our products at many of them, and forged partnerships at others. Among the many events we took part in:

- The massive PROMAT show on supply chain automation

- The Robotics Summit and Expo in Boston

- IROS 2023 in Detroit

- Robot World in Korea

- The Aerial Evolution Association of Canada annual conference and exhibition

- CAV Canada, the conference for Connected and Autonomous Vehicles

There were more, of course. But these were the highlights.

Below: Unitree’s new “Digit” biped robot, at IROS in Detroit

INDRO’S TAKE

Every year at InDro Robotics is busy, with many milestones reached. But 2023 was a little bit different. There were more projects, more milestones, new partnerships – and more clients. The company continued to scale, with the hiring of many more engineers and supply chain/admin staff.

The addition of InDro Forge is a highly significant addition to our portfolio, offering rapid prototyping and custom fabrication for clients, as well as new onsite capabilities for our own projects. And, because this post focussed exclusively on InDro Robotics, we didn’t even get into the amazing things happening at sister companies Aerometrix (which focuses on gas detection) and Bravo Zulu Secure, our drone detection/mitigation operation. Look forward to hearing more about those companies in 2024.

“2023 was an exceptional year at InDro. The company continued to scale, and our engineering team yet again outdid itself with new products, new milestones – and continued commitment to hard work and innovation,” says InDro Robotics CEO Philip Reece.

“Our management and sales teams also pushed the envelope, bringing in major ongoing projects that we look forward to revealing in 2024. And our marketing and content leads made great inroads in getting out the word about what InDro’s been doing, along with our continued growth trajectory. I’m grateful to all of our staff, our clients, and our many partners – with a special thanks to Area X.O, Invest Ottawa, and YOW. Here’s to 2024!”

On behalf of everyone at InDro Robotics, we wish you a Happy, healthy, and productive New Year.

As always, if you’d like to get in touch feel free to contact us here.