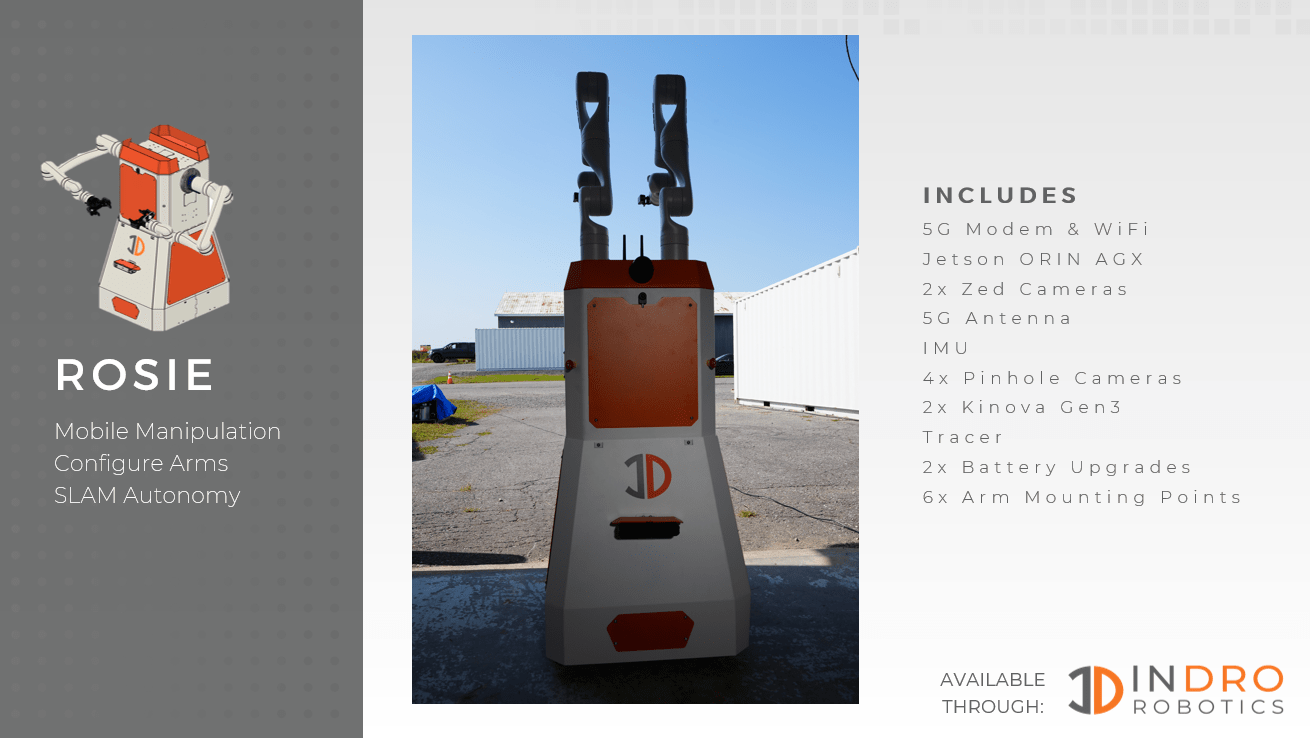

Dual manipulator Rosie the robot used for Industry 4.0 research

By Scott Simmie

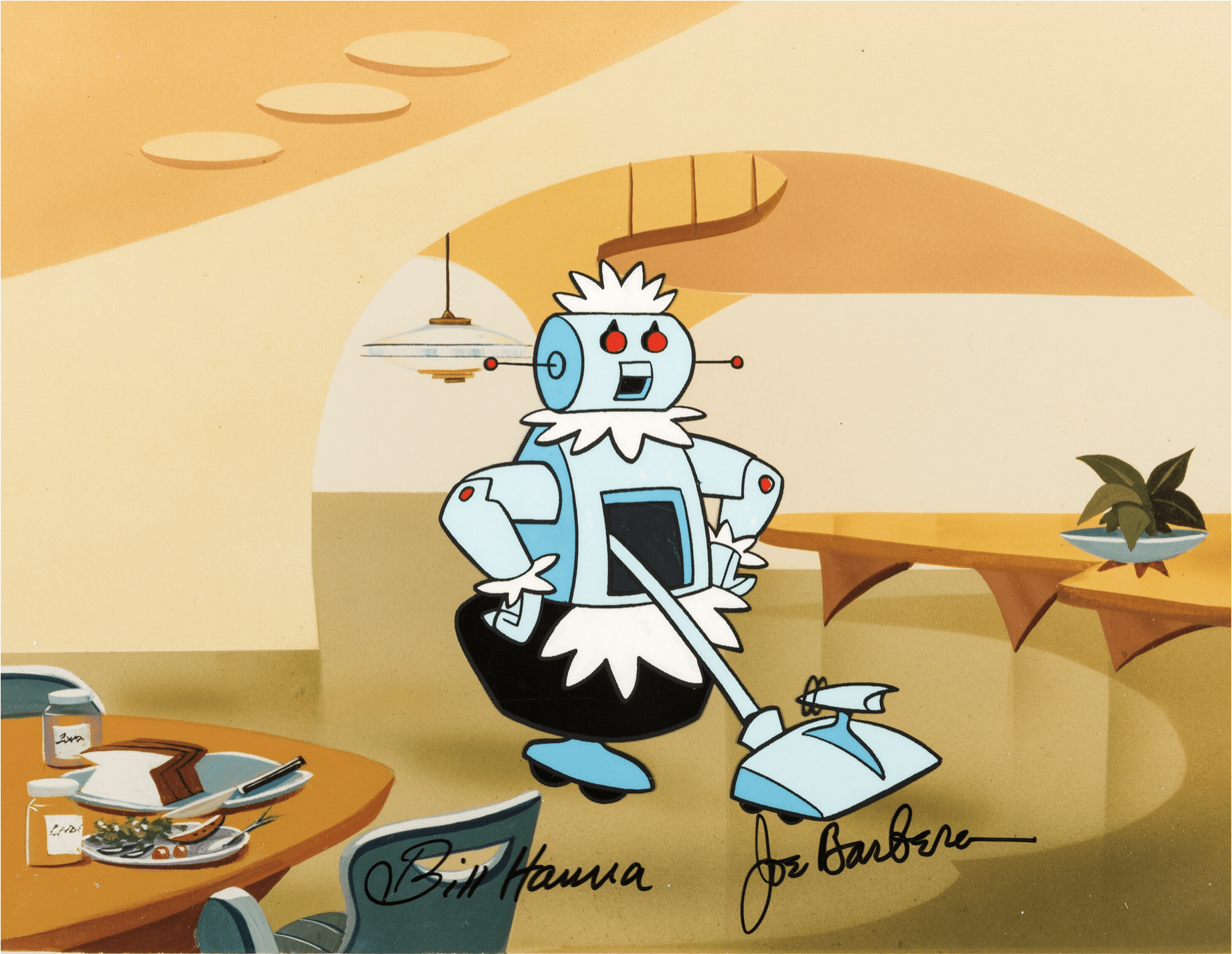

At least some of you will remember The Jetsons.

The television series, created by Hanna-Barbera Cartoons Inc., was a space-age version of The Flintstones (another Hanna-Barbera production). It originally aired in 1962-1963 with later episodes created in a reboot from 1985 to 1987.

But while Fred Flintstone drove a stone-age car (complete with stone wheels) that he powered by pushing his feet along the ground, George Jetson and his family lived in Orbit City, where Jetson commuted to his two-hour per week job via a flying car with a bubble top. And instead of having dinosaurs (including pterodactyls) help carry out tasks, The Jetsons live in a future where they’re surrounded by automated devices. You could think of their surroundings as the 1960s vision of the Smart Home.

And an integral part of that home? Well, that would be Rosey (later changed to ‘Rosie’) the robot.

Rosey was the family’s robotic maid. She carried out tasks that weren’t performed by the many other automatic conveniences that filled the Jetson’s home. She had two manipulator arms and an internally stored vacuum that be deployed on demand.

She was very useful around the house, carrying out tasks to save the family time.

And this story? Well, it’s about our own Rosie – which is also very space-age.

Below: A Rosie the robot publicity cel, signed by show creators William Hanna and Joseph Barbera. The cel was auctioned in 2018; image by Heritage Auctions

THE ROSIE STORY

So. What is Rosie? We asked Head of R&D Sales Luke Corbeth for a snapshot.

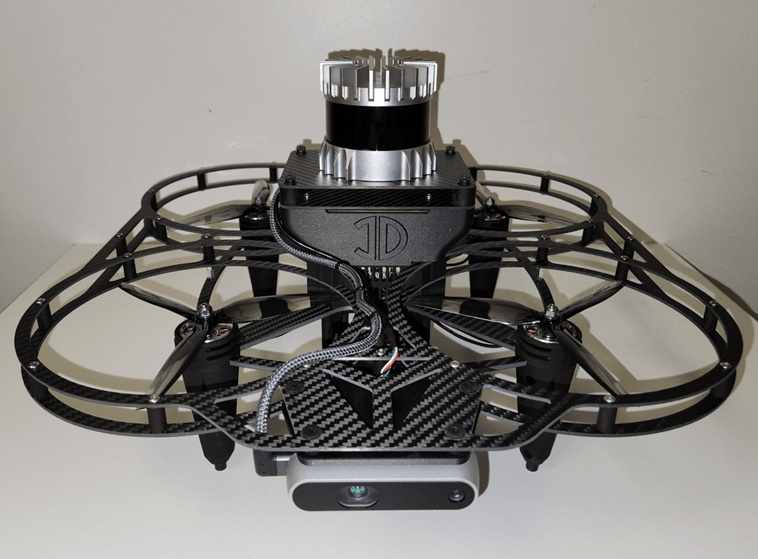

“Rosie is a dual arm mobile manipulation robot designed for pick and place in an industry 4.0 setting,” he says. In other words, it has two arms and manoeuvres on a wheeled platform, and is capable of moving objects from one location to another or even manipulating a single object with both end effectors.

And Rosie has a few tricks up her sleeve. Or, more accurately, sleeves.

“The actual robot is very unique because it has six mounting points for the arms. So you can mount the arms on top, high on the side or low on the side to access shelving of different heights. In fact, you could actually mount one arm directly on the top right, for example, and then mount the second one on the bottom left. So you could grab something from the top of the shelf and from the floor at the same time, which is kind of cool, right?”

Yes, indeed.

Rosie’s home is not with the Jetsons (she has no vacuum cleaner) but in a new lab that hasn’t yet been officially launched at Polytechnique Montréal. It’s called the Intelligent-Cyber Physical System Lab, or I-CPS. So we contacted Lionel Birglen, a professor with the Department of Mechanical Engineering. We wanted to learn more about what the lab does, what he does – and what plans he has for Rosie (which InDro built and shipped in 2023).

Dr. Birglen is a PhD Mechanical Engineer, with a specialisation in robotics. He’s particularly interested in – and an expert on – manipulators and end effectors and has designed and built them. He’s written two books, holds three patents, and is the author or contributing author of at least 94 research papers. He’s also – get this – been listed among the top two per cent most-cited scientists in the world in his area of specialisation.

So it kinda goes without saying, but he’s a pretty big deal in this field.

Dr. Birglen has a deep interest in the role robotics will play in the future of industry. And, within that realm, he’s intensely interested in ensuring that robots, particularly those that will be sharing space with human beings on a factory or warehouse floor, will be safe.

And – he emphasises – he doesn’t trust simulations for important work like this.

“Because simulations lie. They lie all the time,” he says. “You have to understand that reality is infinitely more complex than anything you can have in simulation – so actual experiments are absolutely essential to me. They are essential to my work, to my understanding of what robotic manipulation is.”

“I believe in math, but I know that reality is different. It’s more complex, more complicated, and includes so many un-modelled phenomena.”

ROSIE’S JOURNEY

Dr. Birglen knew he wanted a new robot for use in the new lab (which we’ll get to shortly). And he knew he wanted a robot with two manipulator arms.

“Dual-arm robots are, in my opinion, the future for industry applications,” he says.

And while humanoid bipeds grab a lot of attention, they’re far more complex (and expensive) than wheeled robots. Plus, he says, most factory applications take place on a single level and don’t require climbing stairs.

“From a factory perspective, a wheeled platform makes a lot of sense because typically in factories you don’t have, say, five levels connected by stairs.”

So he knew he wanted an autonomous, wheeled, dual-arm robot. And he started, initially, to think of a company other than InDro for the build.

“I came across InDro almost by accident,” he explains. “Giovanni Beltrame told me about you because he has purchased many, many robots from you. He said: ‘Those guys can build and assemble the robot for you. They’re close and they do a great job.’ So that’s how I came in contact with you.” (We’ve written previously about the amazing work Dr. Beltrame is working on involving robots and space. You can find that here.)

And so, after a number of calls with Luke Corbeth and the engineering team to settle on design and performance parameters, work on Rosie began.

Below: Technologist Tirth Gajera (‘T’) puts the finishing touches on Rosie in 2023

THE LAB

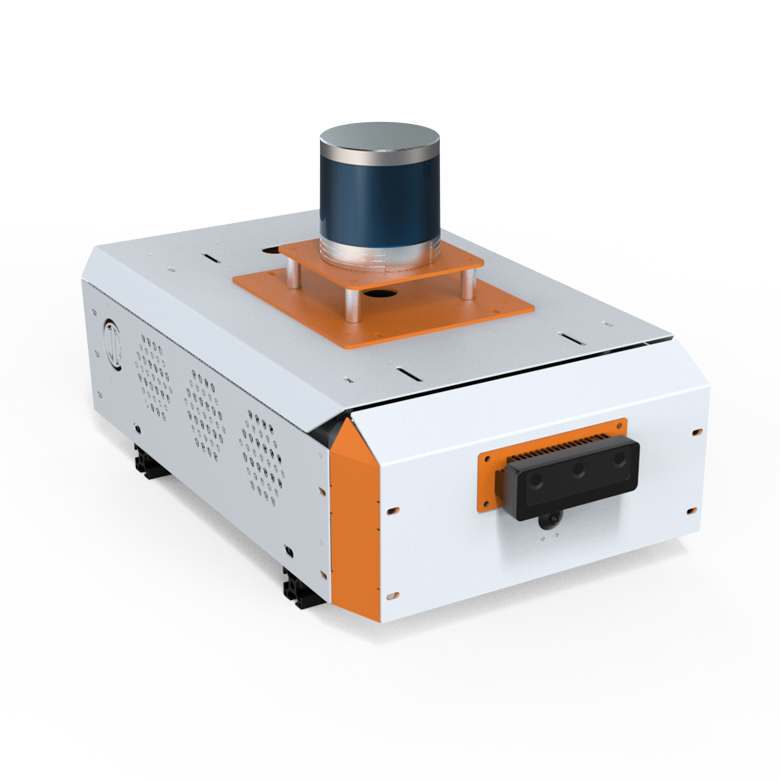

Polytechnique Montréal’s Intelligent-Cyber Physical System Lab (I-CPS) is set up as a highly connected Industry 4.0 factory. Faculty from four different departments – computer engineering, electrical engineering, industrial engineering and mechanical engineering (Dr. Birglen) – are involved with the lab. Interns and students, under supervision, also work in the facility.

“So we have four departments involved in this lab and the idea is to build a small scale factory of the future, meaning that everything is connected. We are building a mini-factory inside this lab,” he says.

So think of cameras that can track objects on shelves – and people and robots within the environment. Think of smart tools like a CNC machine, which will eventually be operated by Rosie. And, perhaps just as important as the connectivity within the lab, is connectivity to other research institutes in Quebec, including Université Laval, Université de Sherbrooke and École de Technologié Supérieure (ÉTS). All of those institutes are working with similar mini-factories, and they’re all connected. There’s even a relationship (and connectivity) with manipulator manufacturer Kinova. Funding came via a significant grant from the Canada Foundation for Innovation, or CFI.

“So think of our lab as like one node of this network of mini-factories around Quebec,” explains Dr. Birglen. That connectivity of all components is still a work-in-progress, but “ultimately the goal is that there is a cyber-connection between these different mini-factories, these different laboratories around Quebec, so that one part of one node can work in collaboration with another node in realtime.”

Plus, of course, a lot of learnings will take place within the individual labs themselves.

“We want to bring collaborative robots to work in tandem with humans,” he says. “We want our robots to safely move around people, we want robots to help people. And we also want robots to learn how to work from people.”

SAFETY, SAFETY, SAFETY

As mentioned earlier, there’s a huge emphasis on safety. And while there are international safety standards for collaborative robots, even a ‘safe’ cobot can pose a threat.

“All the collaborative robots that you have currently on the market more or less follow this technical standard and they are more or less safe, but they’re still dangerous,” explains Dr. Birglen. “And the classical example that we’ve all heard, and which is true, is that if a safe cobot has a knife in its hand and is moving around – it is very dangerous.”

So safety in the lab(s) is paramount – and that means safety at multiple levels. There must be safety:

- At the task level; you must not have tasks that could endanger people

- Safety at the control level

- Safety in terms of collision detection, mitigation, obstacle avoidance

- Safety at the data security level

Plus – and this really interests Dr. Birglen – you must ensure safety with any additional mechanical innovations that are introduced.

“What you develop, any mechanical system you develop, must be as much as possible intrinsically safe. And actually that’s one of the topics I’m currently working on is to develop end effectors and tooling that is intrinsically safe.”

Below: A LinkedIn post from Luke Corbeth shows Rosie, using both arms, inside the I-CPS lab

THE FUTURE

And why is research like this so important? What difference will it make to have robots and humans working safely together, with safe manipulators and end effectors that might even be able to, for example, lift an object in concert with a human being? And why the focus on interconnectedness between all of these facilities?

Well, there’s obviously the value of the research itself – which will lead to greater efficiencies, improved manipulators, gripping technologies, new algorithms and AI enhancements – as well as enhanced safety down the road. But there’s a much bigger picture, says Dr. Birglen, especially if you can get your head around thinking about the future from a global perspective.

China, he says, is no longer a developing nation. The days when the words “Made in China” meant poor quality are – with rare exceptions – gone. The country is, in fact, highly developed – and working at breakneck speed when it comes to innovation and adoption of robotics at scale. A revolution is underway that has massive implications for competitive advantage that simply cannot be ignored. So the research at I-CPS is not merely important from an academic perspective, it’s strategic when viewed through a global economic lens.

“We as a country – meaning Canada – are in competition with other countries for manufacturing, for producing goods and services. China is a developed country and it is very, very, very good in robotics,” he states. “You know how in the past we saw China as producing low quality goods, low quality robots? That’s over, man. That’s finished.”

And?

“If they are investing in robotics like mad and we are not, we’re going to be a leftover – Canada is going to sink as a rich country. If you want to produce wealth in the 21st Century, you need robots, you need automation, you need integration. In short, you need to be the leader of the pack or you’re going to be eaten.”

It’s a stark warning – and it’s true.

I step outside as author and state this having lived in China back when it was still a developing country in the late 1980s – and having returned several times since then. The transformation has been nothing short of astonishing. How, you might ask, did it achieve all this?

The answer has its genesis with former Chinese leader Deng Xiaoping. who led the country from 1978 to 1989. He didn’t merely open the door to reform; he created policies that began sending waves of students from what had been a xenophobic country abroad to study. There was an emphasis on careers that could help modernise the nation, including all aspects of engineering, aerospace, construction, transportation, architecture, etc. That’s where all this began.

Thankfully (and with credit to federal funding agencies like CFI), there are projects like I-CPS underway – and academics like Dr. Lionel Birglen with the vision to push the needle safely forward.

Below: “Baxter” – the original dual-arm robot. Baxter is still at Polytechnique Montréal, but Rosie is the mobile future. Photo by Luke Corbeth

INDRO’S TAKE

We’re obviously pleased Polytechnique Montréal selected InDro to build Rosie. And we’re particularly pleased to see that she’s being deployed at I-CPS, as part of an integrated and networked research project that has such potentially profound implications for the future.

“I believe Dr. Birglen is correct in his assessment of the importance of robotics and automation in the future,” says InDro Robotics Founder and CEO Philip Reece. “And when you throw innovations with drones and even autonomous Uncrewed Aerial Vehicles capable of carrying large cargo loads and passengers into the mix, we are actually heading into a Jetsons-like future,” he adds.

“I think there’s a growing understanding of the implications of this kind of future from not only the private sector, but also federal regulators and funding agencies. At InDro our mission will always focus on continued innovation. Sometimes those innovations are our own inventions, but a key piece of the puzzle is R&D work carried out by academics like Lionel Birglen. We’re confident that Rosie’s arms are in the right hands.”

Interested in learning more about a custom robotics solution? Feel free to contact us here.