InDro completes design, build and delivery of robots for swarm research

By Scott Simmie

You’ve likely seen swarm behaviour in nature – or at least video of it.

Flocks of starlings produce incredible patterns known as murmurations, undulating with split-second speed. Certain species of termites build massive and complex mounds, complete with sophisticated ventilation shafts to ensure air exchange and temperature regulation. Some types of fish, when attacked by predators, form tightly whirling balls as a defense mechanism. Bees build complex hives and have specific roles that all contribute to the collective. And ants, as you’re aware, can do a lot more than spoil picnics.

All of these, though very different, are examples of swarm behaviour. No single individual is in charge, yet these creatures work together to great synergic effect.

Below: A starling murmuration at Rigg by Walter Baxter, CC BY-SA 2.0 via Wikimedia Commons

SWARM ROBOTICS

It was actually through these observations in nature, particularly of insects, that the concept of swarm robotics first emerged.

“In a robot swarm, the collective behavior of the robots results from local interactions between the robots and between the robots and the environment in which they act… The research of swarm robotics is to study the physical body and the controlling behaviours of robots. It is inspired but not limited by the emergent behaviour observed in social insects, called swarm intelligence. Relatively simple individual rules can produce a large set of complex swarm behaviours. A key component is the communication between the members of the group that build a system of constant feedback. The swarm behaviour involves constant change of individuals in cooperation with others, as well as the behaviour of the whole group,” states this Wikipedia entry.

Much of the early research (and some of the more complex, current research) involves high numbers of very simple robotic devices. But as the field has developed, so too has the size and capabilities of the robots being used in swarm applications and research.

“The idea behind swarm robotics is the robots are able to communicate with each other and thus improve their decision-making and data acquisition in a given environment from a real world application standpoint,” explains Head of R&D Sales Luke Corbeth.

THE BOSTON EXAMPLE

One InDro client, Boston University, is using a very large fleet of small but smart robots called LIMO in swarm scenarios. One aspect of their research involves how autonomous vehicles interact with each other. Can the robots detect others merging and take appropriate action? How can autonomous vehicles detect and interact with robots that have been programmed to behave as if they’re human-driven vehicles?

Research like this is obviously more practical (and far less costly) to carry out in a lab rather than on city streets. It’s important work as we head toward the Smart Cities of the future, where eventually all vehicles will be autonomous – and much of the current infrastructure (traffic lights, stop signs) will no longer be necessary because all Connected Automated Vehicles will be part of a network.

“These vehicles become nodes in an Internet in which the vehicles talk to each other,” said Christos Cassandras, Distinguished Professor of Engineering, Head of the Division of Systems Engineering, and Professor of Electrical and Computer Engineering in an earlier interview with InDro.

“They exchange information and so, ideally cooperatively, they can improve metrics of congestion, of energy, of pollution, of comfort, of safety – perhaps safety being predominant.”

It’s fascinating work, and you can check out our story about it here.

But the ability of swarms to move and collect and share data collaboratively also opens up other use-case scenarios.

“If you are able to team your robots together, obviously you can cover a lot more area in a shorter period of time because the robots are essentially building a map together rather than being dependent on a single robot to build that map. One of the most obvious applications is search and rescue,” says Corbeth.

To illustrate, we borrow this example from research being carried out at Carnegie Mellon University:

INDRO’S CUSTOM SWARM

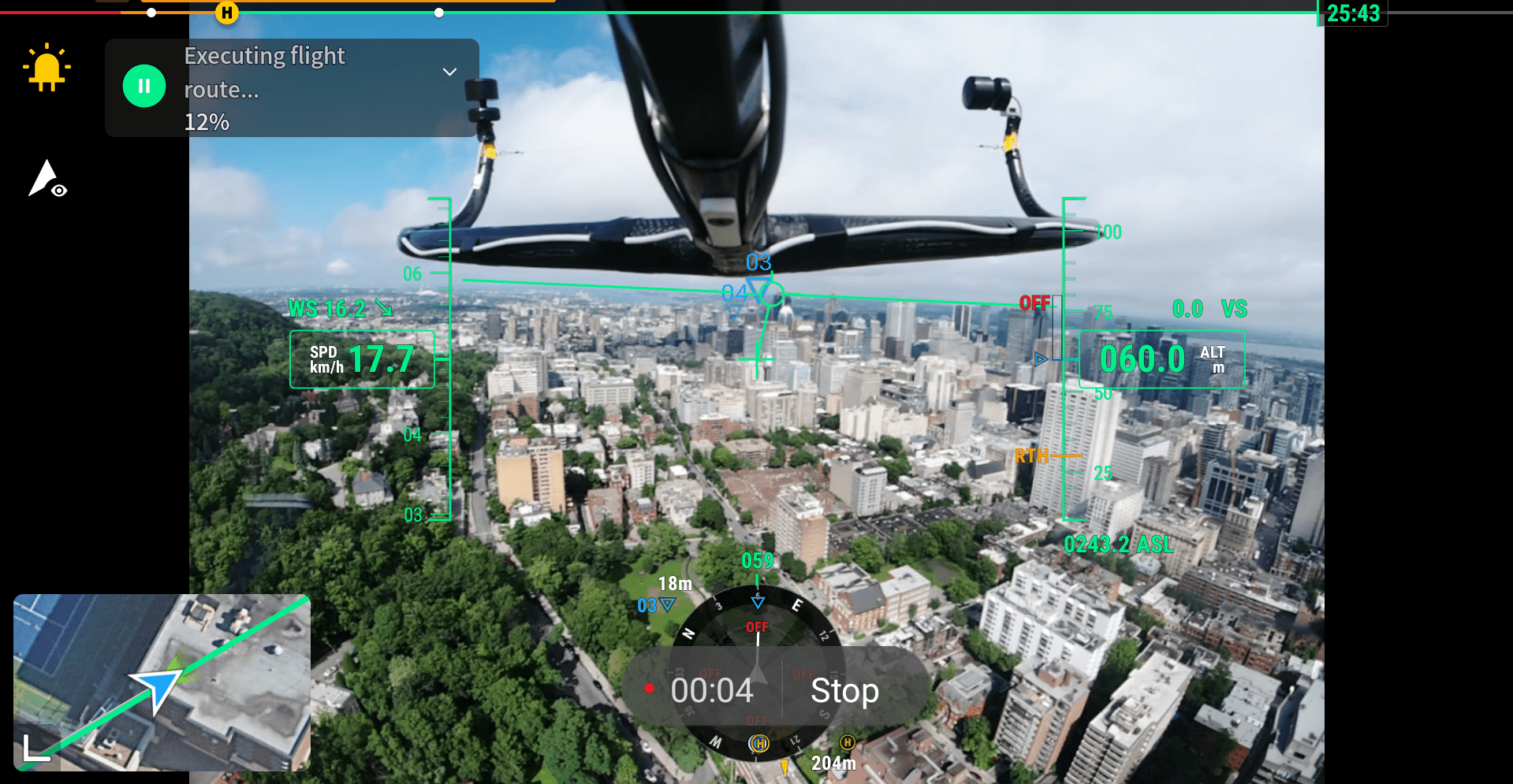

We recently built and shipped four identical custom robots for North Carolina State University’s Department of Mechanical and Aerospace Engineering. Corbeth was the conduit, putting together a package that suited their very specific needs. It began with selecting one of our 18 available platforms.

“They chose the Scout Mini, which is far and away our most cost-effective platform. And it’s unique in that it’s capable both indoors, like in their lab, but also for outdoor use,” says Corbeth.

That, of course, was just the start. Each robot was outfitted with the InDro Commander, which tucks a lot of power and flexibility within its IP54-rated enclosure. Commander houses the brains or the robot – which in this case is a very powerful piece of compute. Commander is completely customisable based on client requirements and contains ROS1 and ROS2 folders. (It also enables rapid integration and recognition of multiple sensors, and has the option of shipping with either or both of InDro’s autonomy stacks for outdoor or indoor use – think GPS-denied and SLAM. In this case, the client will be building their own autonomy stack, as that’s part of their research.)

And this client wanted Commander equipped with a powerhouse.

“They upgraded from a Jetson Xavier NX to the AGX Orin Developer Kit. That’s the best-in-class onboard compute you can add to a robot these days,” he adds.

That’s not hyperbole. The AGX contains a 2048-core NVIDIA Ampere architecture GPU with 64 Tensor Cores. Unfamiliar with Tensor Cores? They mean ultra fast AI processing.

“Tensor Cores enable mixed-precision computing, dynamically adapting calculations to accelerate throughput while preserving accuracy and providing enhanced security,” states the NVIDIA website. “The latest generation of Tensor Cores are faster than ever on a broad array of AI and high-performance computing (HPC) tasks. From 4X speedups in training trillion-parameter generative AI models to a 30X increase in inference performance, NVIDIA Tensor Cores accelerate all workloads…”

That AI computer is capable of – wait for it – 275 TOPS, or trillions of operations per second. (Yes, it’s kind of hard to get your head around that.)

SENSORS, SENSORS, SENSORS

Corbeth worked with the client to outfit each swarm robot with the sensors needed for the job. Starting with the basics, each robot contains two pinhole cameras (one front, one rear) so the operator can remotely see the robot’s eye view using our proprietary dashboard, InDro Controller. For depth perception, we added ZED X stereo cameras which – like human eyes – see the world in three dimensions. These are used for obstacle avoidance (in conjunction with LiDAR, which we’ll get to).

Connectivity is key with any robot. But when it comes to swarm robotics, it’s particularly important to have high-speed, low-latency communication not just with the controller, but between the robots themselves.

“Obviously doing swarm requires 5G connectivity,” says Corbeth. “So there’s a 5G modem in each robot as well as our Wi-Fi development module. In addition to communication between the robots and with InDro Controller, this also means they can program these robots without having to hard-wire into them. In fact, students or researchers could upload algorithms from pretty much any location – they don’t need to be on-site or on the same WiFi network, which has been the traditional route.”

Each robot features GPS and IMU modules, plus a Robosense Helios RS-5515 32-beam LiDAR module. These sense the environment in three dimensions by rapidly scattering and receiving the reflections from eye-safe laser beams. It allows the robot to safely navigate and map in completely unfamiliar and GPS-denied locations, and even carry out precision scans. We recently featured Robosense in this post, detailing how the quality is absolutely on par with the biggest names in the industry. (Selecting Robosense for this project saved the client close to $80,000 without losing any capabilities.)

Outstanding in their field: A look at the InDro-built swarm fleet just prior to shipping to the client

INDRO’S TAKE

It was a fascinating project to build a small swarm from the ground up for the specific needs of this client. We look forward to checking in with North Carolina State University once the research is fully underway – and will report back to you.

“There’s no doubt that swarm robotics is an important tool, not only in R&D but increasingly in real-world applications,” says InDro Robotics Founder and CEO Philip Reece. “Whether it’s search and rescue, mapping difficult environments at scale, or developing algorithms that will enable Connected Automated Vehicles in the Smart Cities of the future, swarms are synergic tools that produce outcomes far greater than the sum of their parts – and that do so with greater speed and efficiency.”

Interested in exploring options for swarm robotics? Contact Luke Corbeth here.