Research at U of Alberta focuses on robotics for medical applications

By Scott Simmie

You’ve probably heard of the “Three Ds” by now: Robots are perfect for tasks that are Dirty, Dull and Dangerous. In fact, we recently took a pretty comprehensive look at why inspection robots can tick all of these boxes – while saving companies from unplanned downtime.

Generally, that maxim holds true. But a recent conversation with two researchers from the University of Alberta got us thinking that some innovative robotics applications don’t truly fit this description. Specifically, certain medical or healthcare use-cases.

The people we spoke to carry out their research under the umbrella of a body that intersects the robotics and healthcare sectors. It’s called the Telerobotic and Biorobotic Systems Group in the Electrical and Computer Engineering Department of the U of A. It’s under the direction of Prof. Mahdi Tavakoli, who is kind of a big name in this sector. Within that group, there are three separate labs:

- CREATE Lab (Collaborative, Rehabilitation, Assistive robotics research

- HANDS Lab (Haptics and Surgery research

- SIMULAT-OR Lab (A simulated operating room featuring a da Vinci Surgical System)

Broadly, the research can be thought of as belonging to one of two realms: Rehabilitation/assistive and surgical. But what does that actually mean? And how has a robot from InDro been modified to become a smart device that can assist people with certain disabilities?

Let’s dive in.

Below: Could a robotic platform like the Ranger Mini be put to use helping someone with mobility issues? We’ll find out…

HELPING PEOPLE (AND EVEN SURGEONS)

We spoke with researchers Sadra Zargarzadeh and Mahdi Chalaki. Sadra is a Master’s student in Electrical and Computer Engineering and previously studied Mechanical Engineering at Iran’s Sharif University of Technology. Mahdi is also a Master’s student in the same department, and studied Mechanical Engineering at the University of Tehran.

Sadra’s research has focused on healthcare robotics with an emphasis on autonomous systems leveraging Large Language Model AI.

“I’ve always had a passion for helping people that have disabilities,” he explains. “And in the rehab sector we often deal with patients that have some sort of fine motor skill issue or challenge in executing tasks the way they’d like to. Robotics has the potential to mitigate some of these issues and essentially be a means to remove some of the barriers patients are dealing with – so I think there’s a very big potential for engineering and robotics to increase the quality of life for these people.”

That’s not dirty, dull or dangerous. But it is a very worthwhile use-case.

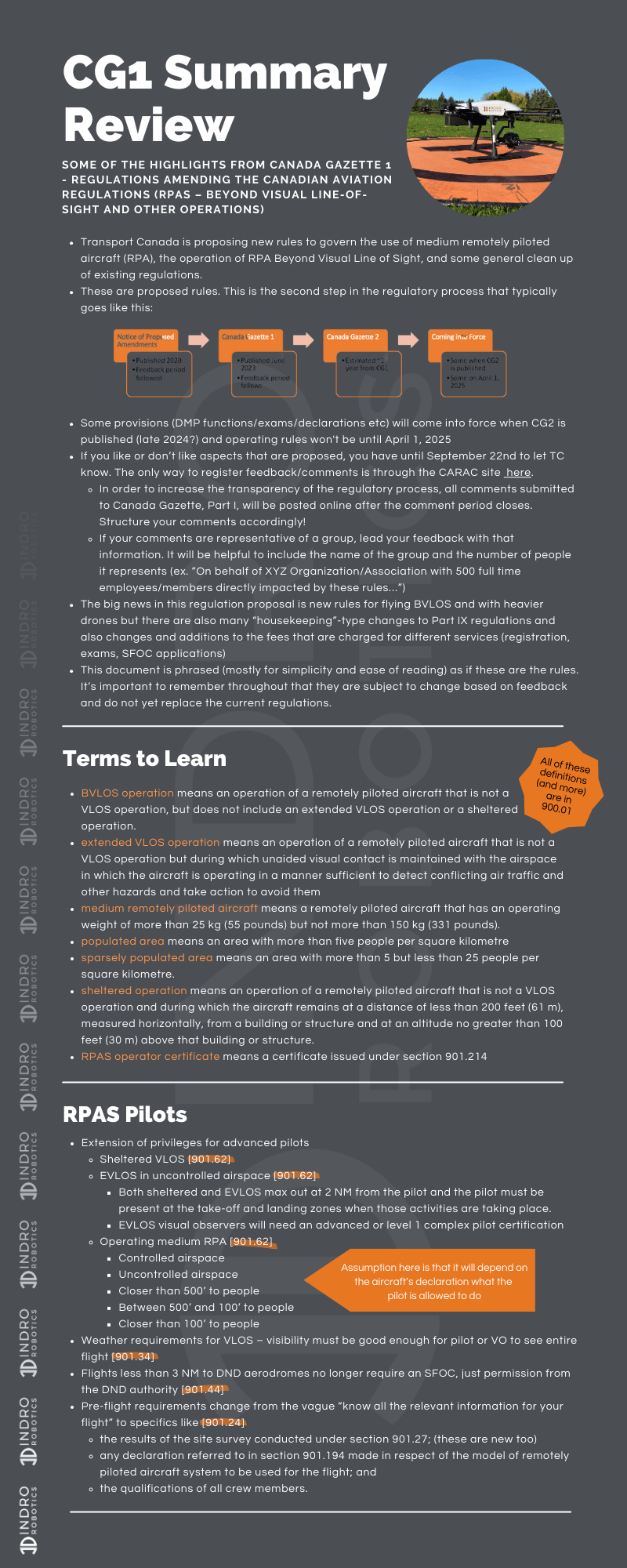

SMART WALKER

People with mobility and/or balance issues often require the help of walkers. Some of these devices are completely manual, and some have their own form of locomotion that keeps pace with the user’s desired speed. The direction of these is generally controlled with two hands on some form of steering device. Usually, equal pressure from each hand and arm are required in order to go in a straight line and by pushing harder on one side or another steering is achieved.

But what about someone who has had a stroke that has left them with partial paralysis on one side? They might well not be able to compensate, meaning despite their intent to carry out a straight path forward the device would turn. That’s where Mahdi’s research comes in.

“Robotic walkers or Smart Walkers have been studied for more than 20 years,” he says. “But in almost all of them, their controllers assume you have the same amount of force in both of your hands. And people with strokes often don’t have the same strength in one side of their body as they have on the other side.”

So how can robotics compensate for that? Well, using an AgileX Ranger Mini with InDro Commander from InDro Robotics as the base, Mahdi and others got to work. They built a steering structure and integrated a force sensor, depth perception camera, and some clever algorithms. That camera zones in on the user’s shoulders and translates movement into user intent.

“We know, for example, if you are just trying to use your right hand to turn left, the shoulder angle increases. If you’re trying to turn right, the shoulder angle on the right arm decreases.”

By interpreting those shoulder movements in conjunction with the force being applied by each hand, this Smart Walker translates that data into desired steering action. As a result, the user doesn’t have to push so hard with that compromised side and it also reduces cognitive load. The wrist torque required by the user drops by up to 80 per cent.

Of course, there’s much more to this device than we’ve outlined here. Enough, in fact, that a scientific paper on it can be found here. You can also check out the video below:

ROBOTS IN THE O-R

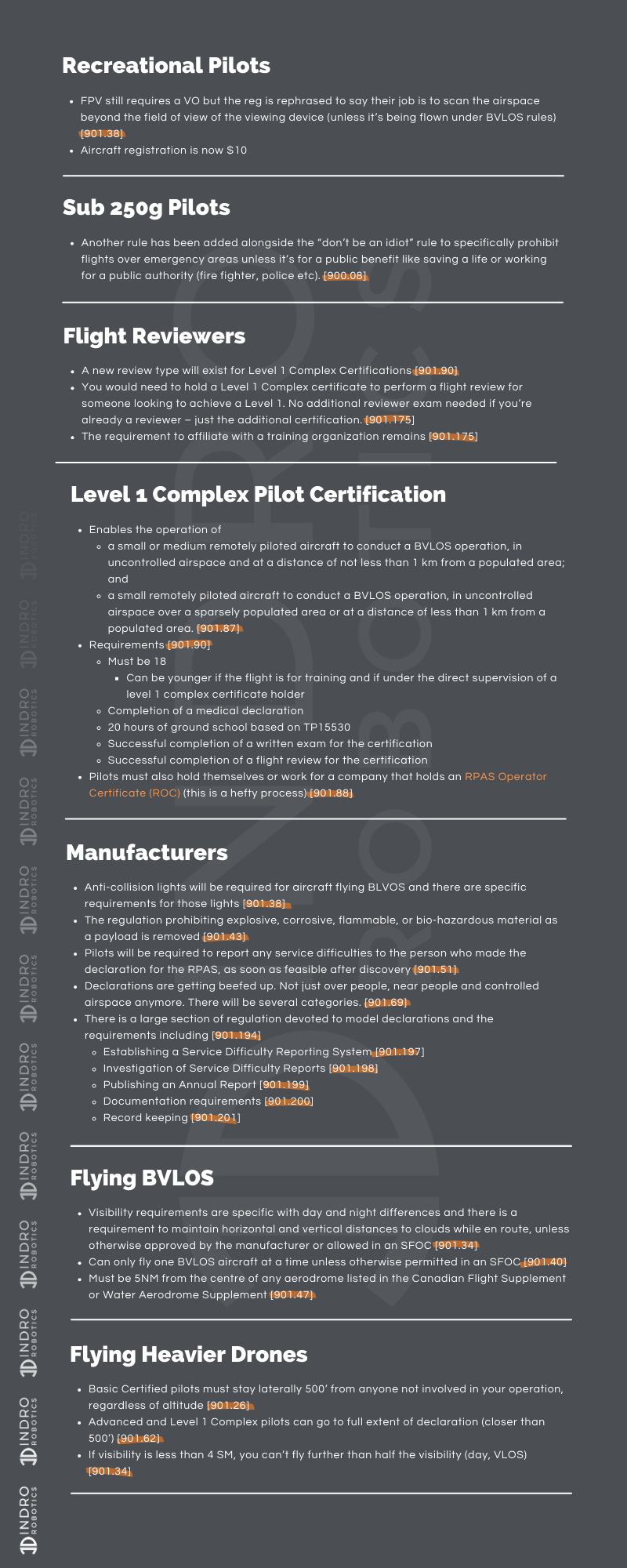

While the Smart Walker is a great example of robotics being put to use on the assistive and rehabilitation side of things, let’s not forget that the Telerobotic and Biosystems Research Group also carries out work on the surgical side. Sadra explains that robotic devices – particularly in conjunction with AI – could prove of great benefit assisting a surgeon.

“My research centres around the use of Generative AI. With the growth of Large Language Models (LLM) such as ChatGPT, we want to see how these AI tools can translate into the physical world in robots. A big section of my projects have focused on Generative AI for surgical autonomy.”

For example, a robotic device with plenty of AI onboard might be able to handle tasks such as suctioning blood. Machine Vision and Machine Learning could help that device determine where and how much suction needs to be applied. And, if you push this far enough, a surgeon might be able to initiate that process with a simple voice command like: “Suction.”

“How can we have task planners and motion planners through generative AI such that the surgeon would communicate with the robot with natural language – so they could ask the robot to complete a task and it would execute?” asks Sadra. “This would allow robots to become more friendly to the average individual who doesn’t have robotics knowledge.”

On the flip side of the coin, there’s also the potential for robotic devices to inform the surgeon of something that might require attention. In breast cancer surgery, for example, an AI-enhanced robot with realtime data from an imaging device might notice remaining tumour tissue and give the all-clear to close the incision only after all cancerous material has been excised.

In other words, some of the algorithms Sadra works on involve working on that human-robotic interface while leveraging powerful Large Language Model systems.

“Exactly. And we look at this process in three stages: We think about high-level reasoning and task planning, then mid-level motion planning, then lower-level motion control. This is not only for surgery; it’s a similar workflow for assistive robotics.”

The head of the lab, Professor & Senior University of Alberta Engineering

Research Chair in Healthcare Robotics Dr. Mahdi Tavakoli, describes AI in this field as “a game-changer,” enabling the next level of human-robotics interface.

“Our focus is clear: We’re building robots that collaborate with humans — robots that can understand our language, interpret context, and assist with the kinds of repetitive or physically demanding tasks that free people up to focus on what they do best: The creative, the social, the human. We see the future in ‘collaborative intelligence,’ where people stay in control and robots amplify human capabilities.”

Fun fact: The most powerful LLMs are known as Generative Pretrained Transformers – which is where ChatGPT gets its name.

WHAT’S NEXT?

We asked the researchers if the plan is to ultimately explore commercialisation. Apparently it’s a little more complex when it comes to surgery due to regulatory issues, but this is definitely on the roadmap. Sadra has been doing research through a program called Lab2Market and says there’s been very positive feedback from clinicians, physical and occupational therapists and manufacturers.

Program head Dr. Tavakoli says the lab is “thinking big” about how such innovations can help diversify the Canadian economy. In Alberta specifically, which has traditionally been a resource-dominated economy, he says robotics presents a huge opportunity for growth.

“That’s part of why we’ve launched Alberta Robotics: To build a regional ecosystem for robotics research, education, and innovation. So, the University of Alberta is open for business when it comes to robotics; people should be watching for what will come out of Alberta in robotics!”

Below: A promotional video for the da Vinci Surgical System. Will research at the U of A someday enable machines like this to take verbal commands from a surgeon?

INDRO’S TAKE

The research being carried out at the University of Alberta is both fascinating and carries with it huge potential in both the surgery and rehabilitation/assistive spheres. We’re pleased to know that three Ranger Mini platforms with InDro Commander are being put to work for this purpose – which is unlike any other use-case we’ve seen for our robots.

“I’m incredibly impressed with what they’re doing,” says InDro Founder and CEO Philip Reece. “It’s researchers like these, quietly carrying out advanced and focussed work, who make breakthroughs that ultimately become real-world devices and applications. We’re pleased to put a well-deserved spotlight on their work.”

You can check out a list of researchers and alumni – and see a photo of Sadra and Mahdi – right here.