InDro Update: We’ve been busy, busy, busy

By Scott Simmie

It’s been a busy summer at InDro Robotics and InDro Forge.

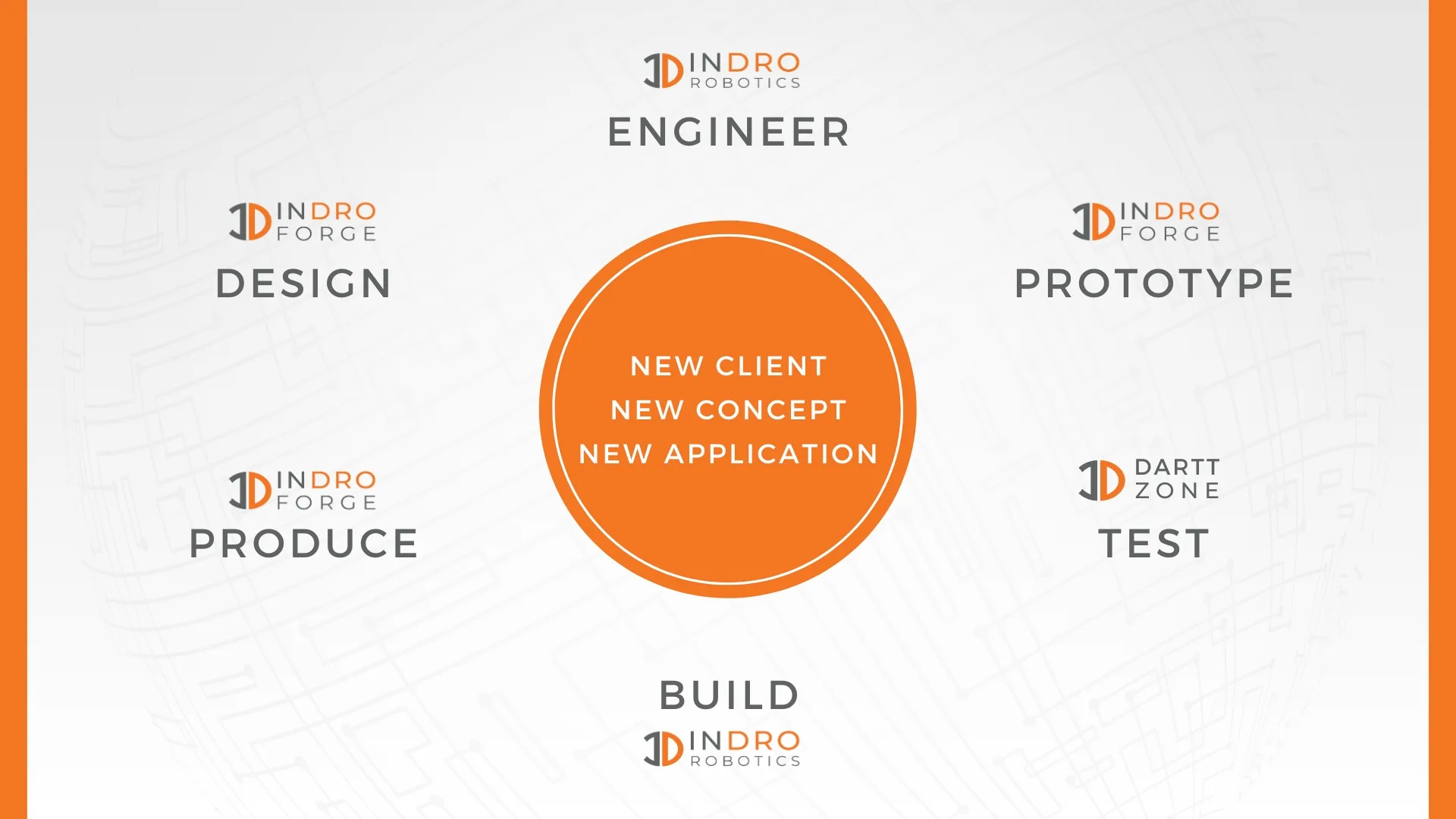

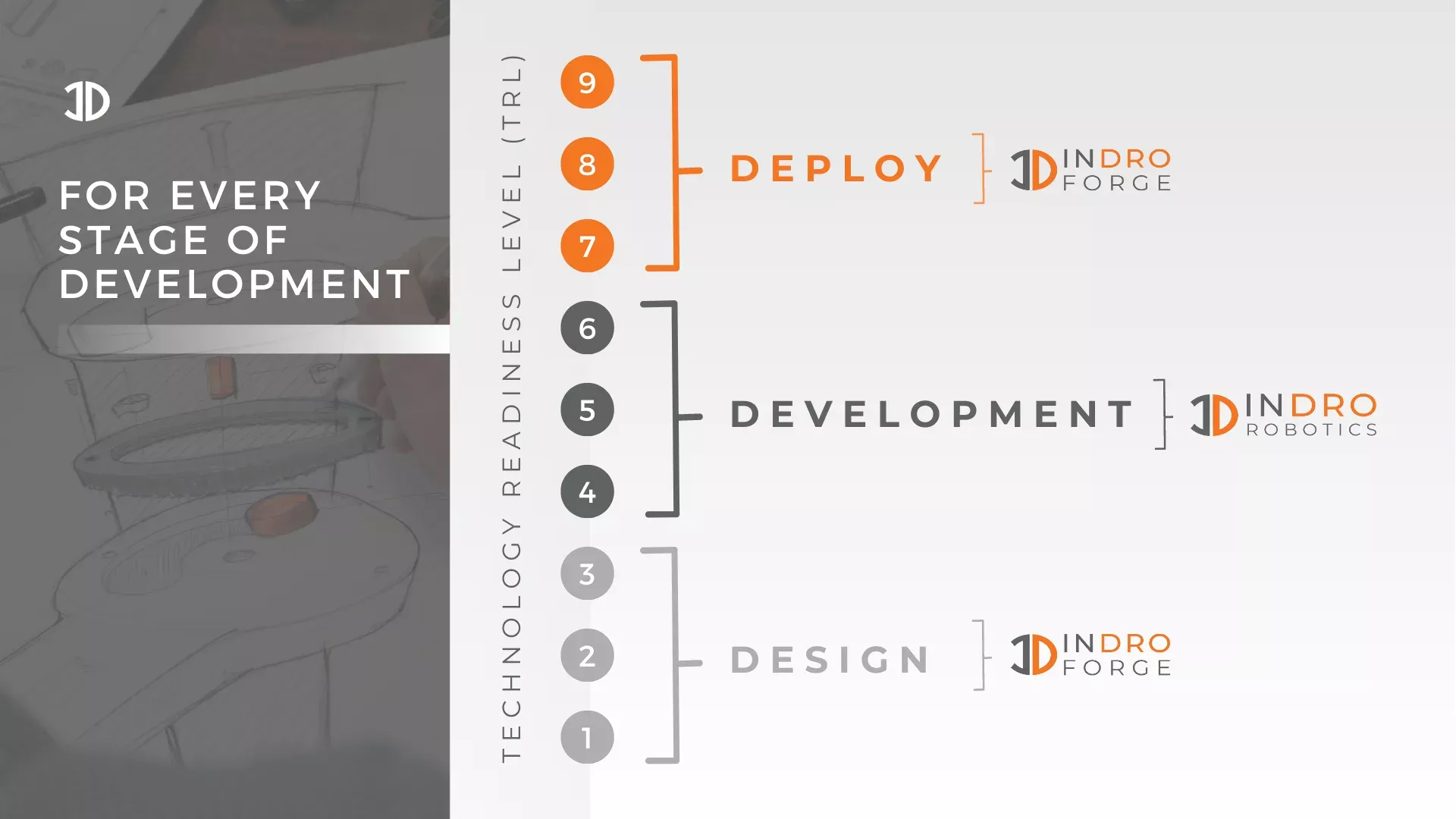

Sure, people have had holidays. But in the R&D world, we don’t have the typical summer slowdown often enjoyed in other sectors. We’ve been busy building new robots, coding new software, carrying out demonstrations for VIPs, signing new contracts and continuing to push innovation boundaries at both our Area X.O and InDro Forge locations.

Area X.O, of course, is our engineering headquarters and the workplace for the bulk of our engineering team. But since we began operating InDro Forge last September, we have significantly expanded capabilities – including new hires. Formerly known as the Bayview Yards Prototyping Lab, InDro Forge (in collaboration with Invest Ottawa) is InDro’s prototype fabrication and integration centre. We take on both custom projects for clients, and also use the equipment and expertise to ‘forge’ much of what goes into InDro products.

And between them both? We’ve been busy, busy, busy.

There are a few projects that we unfortunately cannot reveal due to NDAs. But we can tell you we had a very successful demonstration recently of a quadruped with some amazing autonomy, AI and manipulative capabilities. Wish we could tell you more about that, but we just can’t. Yet.

So let’s get on with what we can talk about. And we’re going to start…with some incredible software we’ve built: InDro Controller.

INDRO CONTROLLER

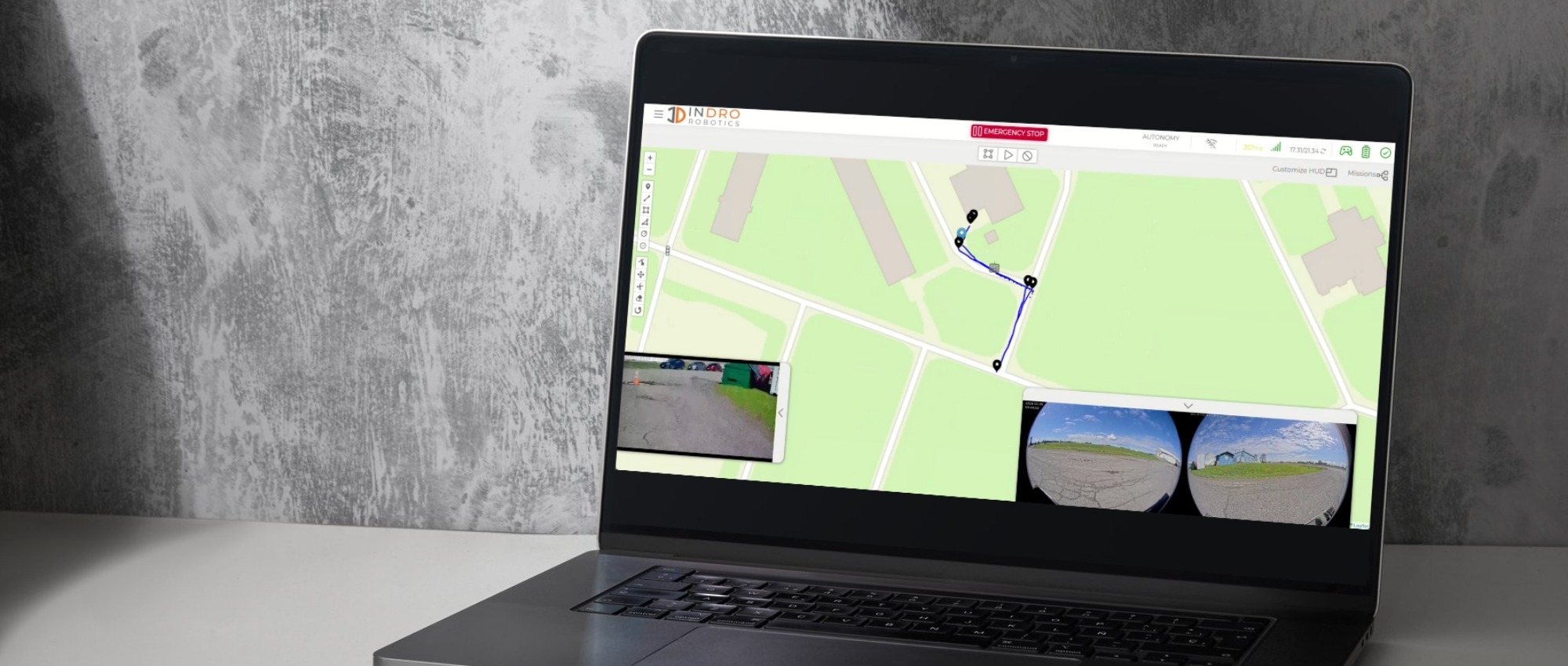

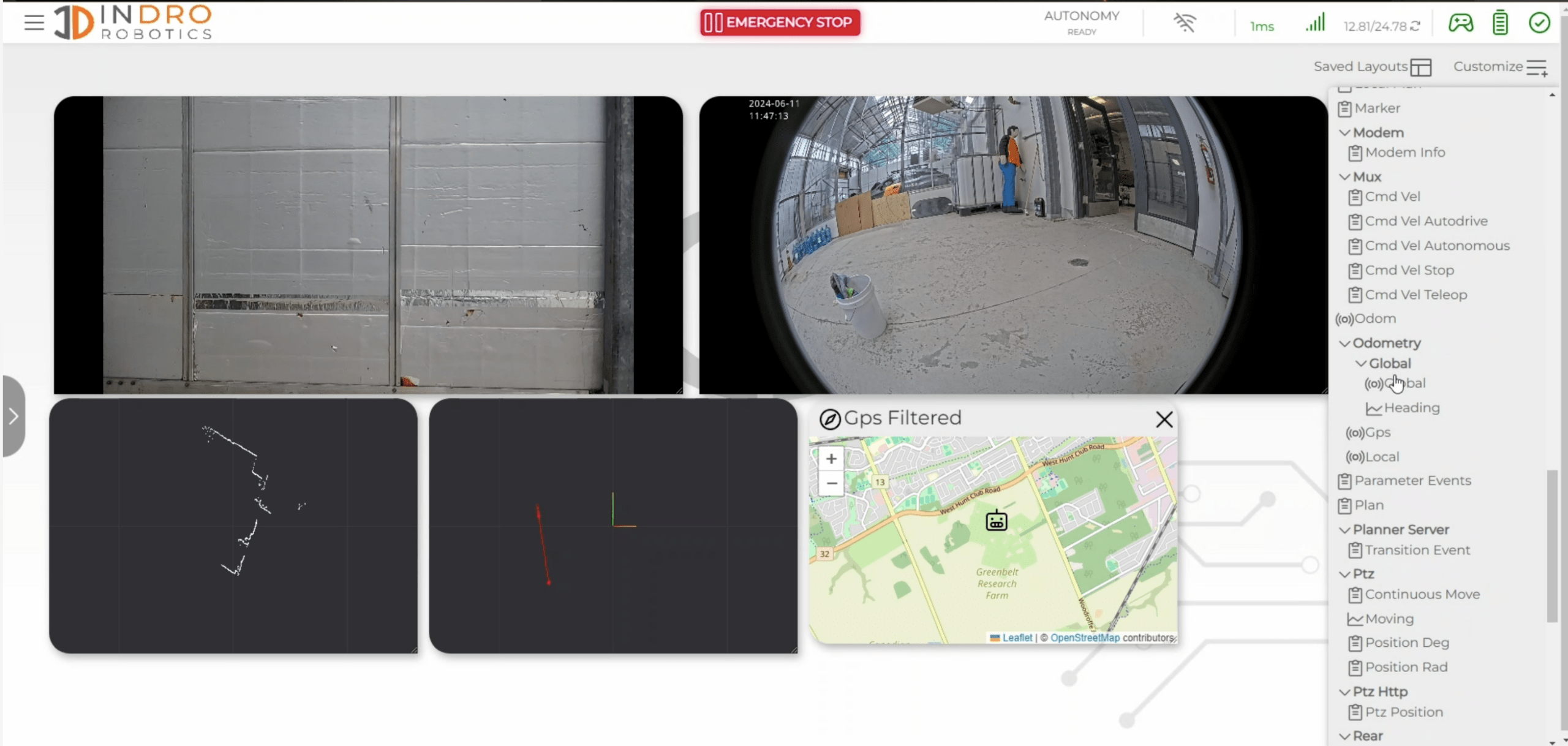

We are very excited about this new software, completely coded in-house. It’s a complete solution to carrying out remote robotic missions, whether they’re manually teleoperated or fully autonomous.

“It’s an all-in-one data visualization, robot management and robot control software,” Front End Developer RJ Bundy explained earlier. “Whether you’re a student first learning how to use a robot or you’re a commercial giant, you’d be able to manage and maintain all of your robots.”

And yes, by that he means this product is completely robot-agnostic.

The InDro Controller software can be uploaded onto any robot. It can then be remotely and securely accessed by laptop or desktop, with all data encrypted. It automatically detects all sensors on board any UGV, and gives the operator complete control over customisation. Want to display thermal? LiDAR data? Need to zoom in on an object of interest? All of these functions – and many more – can be easily carried out remotely.

One of the features we particularly like is InDro Controller’s ability to remember things. Let’s say, for example, you wanted to plot an autonomous mission. With the display showing you a map of surroundings, you simply drive to a desired spot and perform a function. Suppose (as we’ve done), you wanted to stop, pan, tilt and zoom the camera to a specific object for inspection – something like a pressure gauge or other critical piece of infrastructure. Capture that image just once, and InDro Controller will remember exactly what you did and precisely where you did it. Then you move on to the next inspection point, where perhaps you’d like to capture thermal data.

During that first manual mission, every single action and location were saved. So when the time comes for your next run, you simply click the name of the saved mission and the robot (assuming you have GPS or SLAM autonomy onboard) will automatically carry out precisely what you did the first time. All you have to do is look over the data, or use change detection software to carry out that task on your behalf. You can save as many missions as you can come up with.

Speaking of autonomy, some of our clients carry out their own research and write their own software. For those who don’t, we have two InDro Autonomy stacks available:

“We have a GPS-based autonomy – which is better for outdoors – and then we have a SLAM- (Simultaneous Localisation and Mapping) based autonomy which is ideal for indoors,” says Head of R&D Sales Luke Corbeth.

There is also an Academic version available for those who wish to work with their own autonomy stacks. The entire interface is so easy to use, you can literally be up and running and minutes.

INDRO BUILDS, DELIVERS SWARM

There’s long been an interest in swarm robotics, but we’ve noticed an uptick of late.

The concept behind swarms is that the whole is greater than the sum of its parts. A group of individual robots, carrying out tasks on their own while talking to each other, can accomplish far more in a given amount of time than a group of robots operating independently.

“The idea behind swarm robotics is the robots are able to communicate with each other and thus improve their decision-making and data acquisition in a given environment from a real world application standpoint,” explained Head of R&D Sales Luke Corbeth in this earlier post (which goes into considerable detail about the genesis and purpose of swarm robotics research).

For example, it would be vastly more efficient to scan the interior of a large building with four robots that are communicating with each other – ensuring no two robots cover any of the same space. In an aerial Search and Rescue operation, drones can more efficiently cover a large area as a coordinated team than four people piloting independently.

For research institutions, swarm research can be carried out very economically. As we posted earlier, Boston University has a large fleet of economical LIMO robots carrying out a wide variety of swarm-type research.

Below: The four swarm robots InDro recently built and shipped to a client.

ARMED AND READY TO GO

Don’t worry. When we say “armed” we’re talking about a robot with an arm. InDro is not – and never will be – involved in the weaponisation of its products.

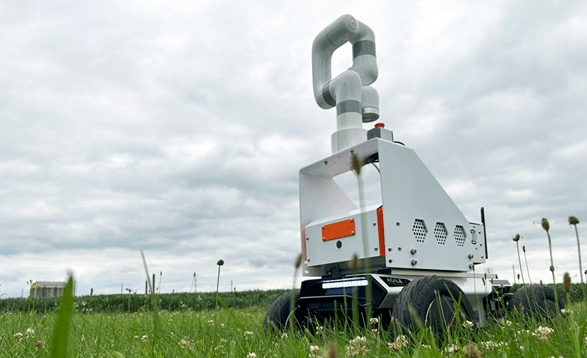

In this case, an academic client wanted a robot that could carry out tasks requiring manipulation in a very specific setting. The client needed a platform that was easy to operate – and that would have a little extra height for the tasks it has in mind. Working closely with Luke Corbeth and the InDro engineering team, we built a custom robot to their specs. That included metal work carried out at InDro Forge in order to elevate the position of the arm.

“This was our latest mobile manipulation build – designed to do manipulation tasks inside greenhouses. The build is on Hunter SE platform with InDro Commander on board for easy sensor integration,” says Corbeth.

“The client plans on integrating its own existing sensors. We added a custom A-Frame to increase the effective height of the manipulator; the arm is the uFactory xArm6 – a highly capable and cost-effective ROS-based manipulator. They’ll be adding their own end effector suited for their research.”

Those into steering mechanisms might find this bit of interest:

“Typically we do these builds on the Ranger Mini – since omni-directional movement means fine adjustments to get into effective manipulation range – but they were keen on Ackermann for improved stability over long distances,” he adds.

It’s a one-off kind of project, something InDro often does for clients. And it’s definitely one-of-a-kind.

Here it is: Out, standing in its field.

SENTINEL V2

Team InDro (along with Team Forge) also designed and built a powerful new iteration of our flagship remote inspection robot, Sentinel. This is a heavy-duty machine intended for the demands of remote infrastructure inspection and monitoring/surveillance.

This was no small task. We integrated multiple powerful sensors, including ZED depth cameras, a 30x optical pan-tilt-zoom, along with multiple LiDAR units for both SLAM and avoiding obstacles and people. And its brains? We’re not sure what the equivalent IQ is, but this UGV is very smart. We integrated the most powerful compute power available from NVIDIA, the Jetson AGX Orin – a powerful 64GB developer kit. You want speed? It can carry out 275 trillion operations per second (TOPS). InDro Autonomy is embedded in Commander, and there’s a Realtime Kinematic (RTK) sensor for centimetre-level positioning accuracy. Oh, we also threw in a ZED BOX (NVIDIA Orin NX), which operates at 100 TOPS.

And the icing on top? It (of couse) works with InDro Controller, enabling users to easily plot and repeat highly detailed autonomous missions.

A CUSTOM, GROUND-UP BUILD

RealLife Robotics, a startup focusing on zero-carbon cargo and last-mile delivery, came to InDro with plans from its own engineering team for a new version of its core delivery UGV, BUBS. InDro Forge is its manufacturing contractor, and – in concert with the additional expertise of our Area X.O staff and in constant communication with the engineers at RLR – got to work.

Though the plans came from RealLife Robotics, every single component from the platform up was fabricated at InDro Forge and integrated by the InDro team – including custom frame, specialised brackets and mounting hardware, sensor integration, cargo bay and sleek exterior shell. That included using the BigRep ONE, a massive 3D printer capable of creating objects up to one cubic metre.

“We’ve built a full skeleton electronic system based on RLR’s designs and a suite of sensors to be able to do the autonomy, as well as an exterior shell that allows them to do remote, last-mile delivery,” says Joel Koscielski, Lead Manufacturing Engineer.

RealLife is currently on a stellar trajectory and is gaining a lot of investor traction. It was recently rewarded with significant funding from the Canadian Food Innovation Network through its FoodTech Next program. It had previously been demonstrating BUBS V1 across the country, and just unveiled the extremely capable new version at a high-profile event at the Toronto Zoo.

“Knowing that the fabricators at Forge have the same depth of engineering experience as our own team builds the trust you need to move fast and meet budgets for a project like this….. The fact they are also a Canadian tech startup and not far away is a bonus,” says RLR Founder and CEO Cameron Waite.

Below: The new BUBS, complete with Zebra wrap for the Toronto Zoo event

PEARS, CHERRIES, DRONES AND ROBOTS

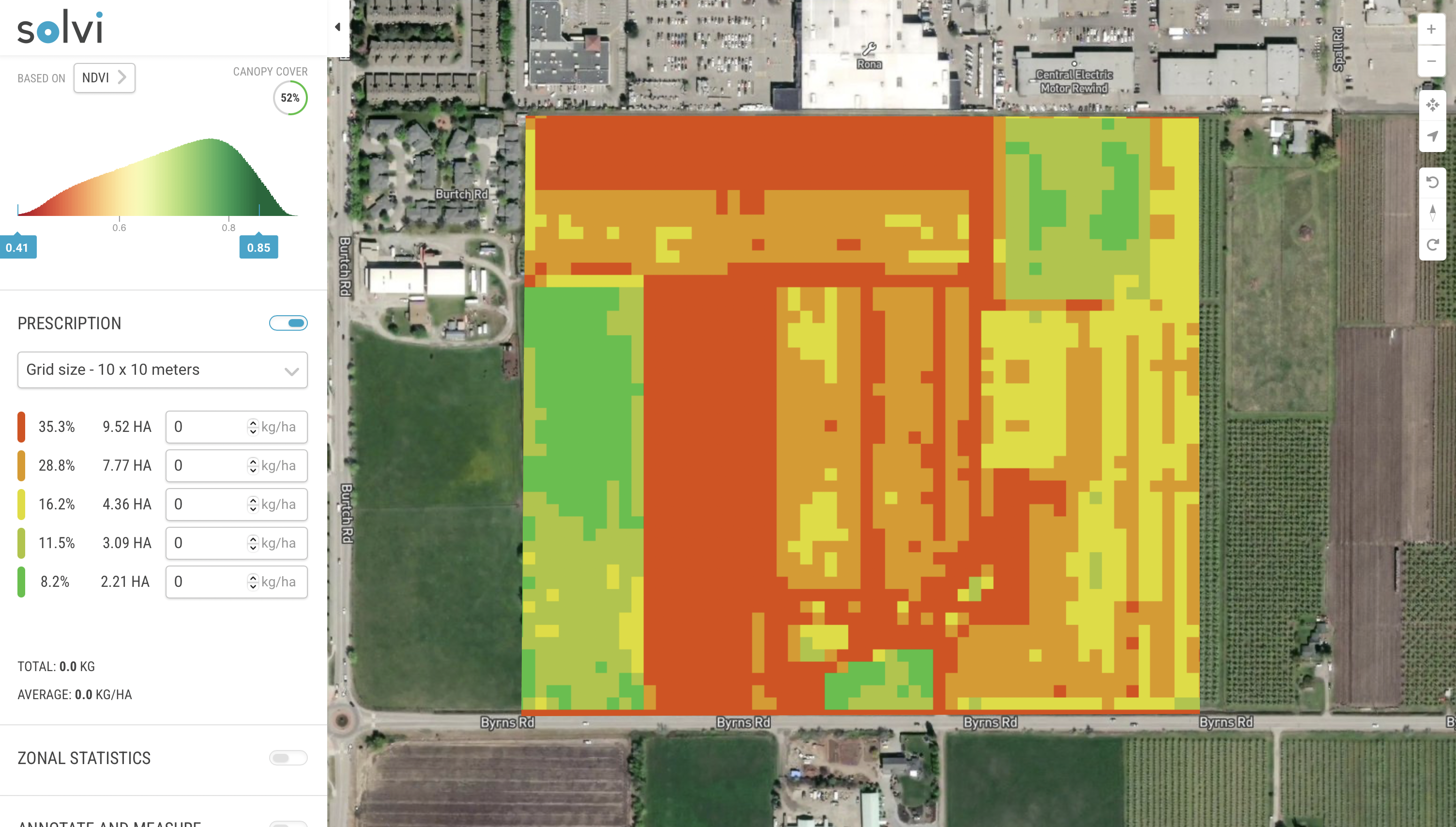

While the bulk or our operations take place at Area X.O and InDro Forge, we’ve also been busy elsewhere. In this case, in British Columbia. There, we’ve been carrying out precision agriculture work in peach and cherry orchards. It’s part of an ambitious and innovative two-year project – a collaboration between InDro Robotics and the City of Kelowna (enabled with funding from Agriculture and Agri-Food Canada’s Agriculture Clean Technology Program).

But this isn’t just any precision agriculture project. Yes, we’re flying multi-spectral missions every two weeks over these farms, then drilling deep into the data to explore all parameters of crop health (chlorophyll levels, nutrients, any indicators of pests or disease etc.). That data provides valuable insights, explains Chief of Flight Operations Dr. Eric Saczuk (who holds a PhD in remote sensing and runs BCIT’s RPAS Hub).

“Is it healthy? Is it not healthy? Is it being productive? Is there chlorophyll? If so, how active is it?” he says.

“These are the kinds of questions we can answer when we do what we call ‘multispectral band combinations.’ And it gives us a really clear picture that cannot be detected by the human eye.”

What truly sets this mission apart is that it’s not just drones involved. InDro will be deploying ground robots, carrying out autonomous missions with their own multispectral sensors. We will then compare the view (and data) from the top-down and the bottom-up.

“This is a way of doing ground-based validation of what we’re seeing from the air,” says Dr. Saczuk.

Once that validation is complete, if there are any areas that require attention then precision spraying will be carried out by an Agras industrial spraying drone, and possibly by ground robots as well.

“Anything in agriculture, the more information you get, you’re not going to be worse off,” says Riley Johnson, a manager at Byrnes Farms – one of the two locations where the project is being carried out.

“Especially for new farmers coming into the industry, any new kind of information can help out ten-fold – particularly if you’re on new land. Any information outside of the Old Farmer’s Almanac is always appreciated.”

Below: Data from the Kelowna project, followed by an image of Dr. Saczuk with the Agras drone

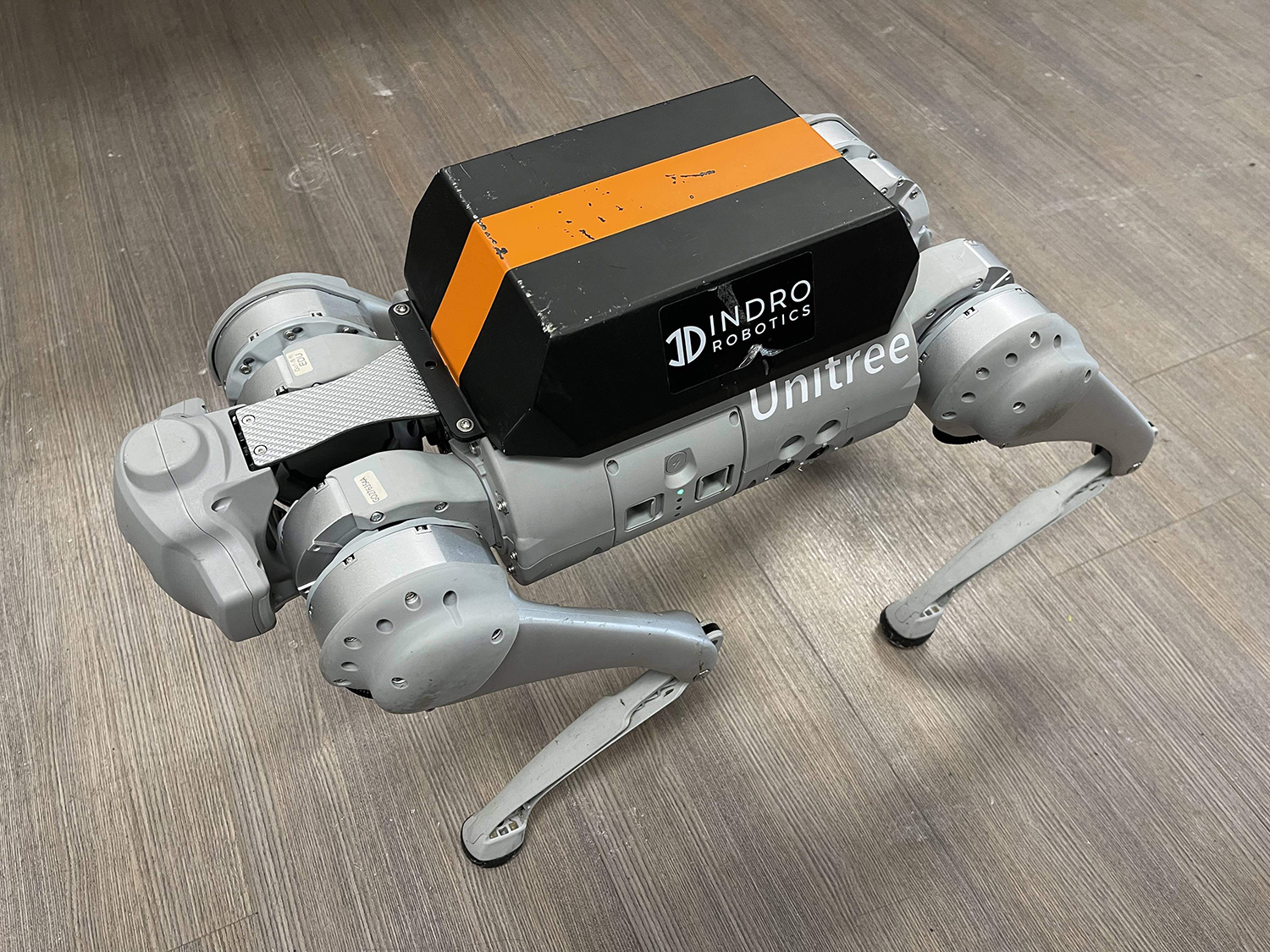

WAIT, THERE’S MORE

We’ve also built a very sophisticated system involving a jacked-up industrial quadruped (where we’ve installed the InDro Backpack (a smaller version of InDro Commander), along with a manipulator arm and some very special capabilities. Unfortunately we can’t tell you much more about that one, due to NDA. But we can say we had a very successful demonstration for VIPs in late July. We also have another project, currently under wraps, that will set a new bar for autonomous exploration, scanning and mapping. More on that to come.

We also continued to elevate the capabilities of our Street Smart Robot, designed to detect anomalies along bike paths in winter. If the SSR’s AI senses potholes, ice, unexpected obstacles or generally anything that might impede safe cycling, that data can be relayed instantly to municipal maintenance crews. We completed the project and successfully demonstrated its capabilities at Area X.O this summer as well.

In addition, InDro’s Dr. Eric Saczuk and Pilot Jon Chubb helped support SkyScoutAI, an innovative company that’s set to be a game-changer in the detection of wildfires and the protection of critical infrastructure in cities threatened by this growing danger. The company has exclusive rights to an amazing fire suppressant product which can be sprayed with a drone tanker onto the roofs of buildings that may be at risk. What SkyScout is doing is pretty amazing, and it’s worth checking out this read. Dr. Saczuk was also busy this summer carrying out methane detection on behalf of Aerometrix in Michigan.

Come to think of it, I’ve been busy too. In addition to covering all the developments above, we’ve also started to profile some of the members of Team InDro and Team Forge who help us achieve the many things we do. You can take a dive into how we work with clients with this profile of Head of R&D Sales Luke Corbeth (who set up and ran his own auto-detailing business while in Highschool before making the leap to robots, drones and sales). And, ICYMI, we just published a feature on Forge Project Manager Stephan Tzolov. He nearly became a doctor, but was just too creative for that field. It’s really quite the story.

Below: Luke Corbeth and Stephan Tzolov

INDRO’S TAKE

As we said in the headline, it’s been busy, busy, busy. InDro people work hard, regardless of the season (but we do give them time off and reward their hard work). Looking at all of these builds and milestones and projects, we cannot help but be proud.

“The teams at InDro Robotics and InDro Forge are truly world-class,” says Founder and CEO Philip Reece.

“We are fortunate to have an incredible sense of shared spirit and collaboration – along with an amazing collective skillset. I couldn’t be more pleased with their accomplishments – along with the pride they take in their work. And, by the way, I work hard too,” he says with a grin.

We hope you’ve been enjoying your summer. And that you haven’t been quite as busy as we are.