Indro Robotics takes in IROS 2023 in Detroit

By Scott Simmie

One of the most important gatherings in the field of robotics is underway in Detroit.

It’s the International Conference on Intelligent Robots and Systems, or IROS 2023. And InDro Robotics is there.

“IROS is kind of an open forum to discuss research in the fields of mobile robotics, manipulation and so much more,” says Account Executive Luke Corbeth. “It gives researchers the ability to collaborate with each other, as well as industry, through the exhibits.”

Or, as the conference describes itself: “IROS is a large and impactful forum for the international robotics research community to explore the frontier of science and technology in intelligent robots and smart machines, emphasising future directions and the latest approaches, designs and outcomes.”

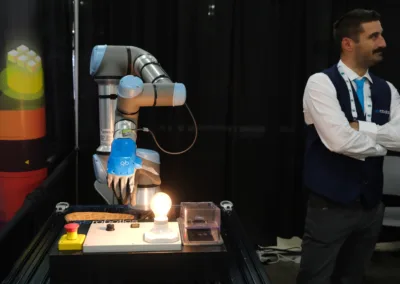

There’s plenty to see (and learn). You’ll find robotic arms and hands – some with incredible dexterity. There are quadrupeds, bipeds, specialised sensors – even a race course where teams put small but fast autonomous racers against one another. Plus, of course, scores of seminars and poster exhibits highlighting new and important research in fields ranging from AI to remote microsurgery.

“Everyone who is working on the cutting edge of robotics comes to IROS to present their research,” says Corbeth.

Some of the best minds in the field – including Masters and PhD students from many parts of the world – come to learn, network and share. Even Amazon is here, specifically to hire people to design, build and operate new robots for its warehouses. So too is the Honda Research Institute.

WHAT IS ROS?

Though IROS stands for Intelligent Robots and Systems, “ROS” has another relevant meaning. In the industry, it stands for Robot Operating System. As ros.org describes it, ROS “is a set of software libraries and tools that help you build robot applications.”

These libraries and developer tools include state-of-the-art Open Source algorithms that are shared with developers around the planet. The original toolkit is known as ROS1, while the newer ROS2 has more robust security protocols and is being embraced at the corporate and industrial levels.

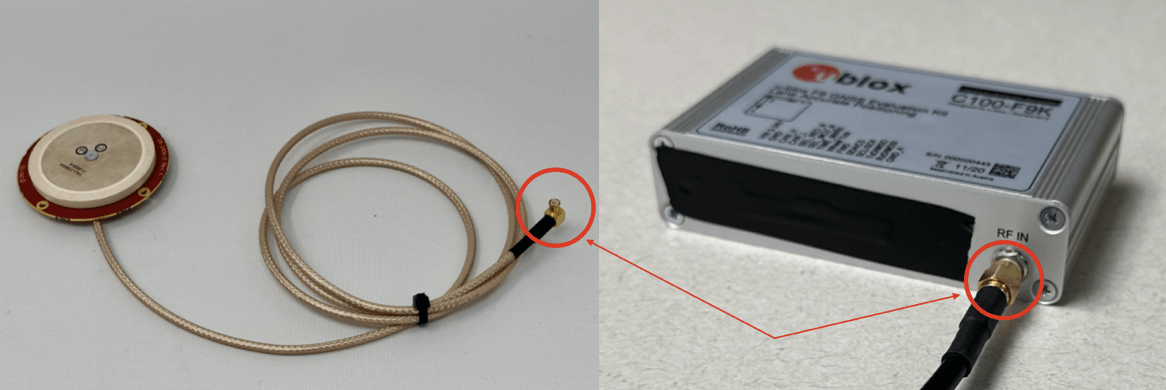

“Generally what is being built here is being built on ROS,” explains InDro Vice President Peter King. He goes on to explain that you can think of ROS as a facilitator that brings all the different parts of a robot – including different sensors and coding – together.

“ROS is language-agnostic,” says King. “You can bring in Python, you can bring in C++, you can bring in other sensors. ROS allows all of the packages to talk to each other.”

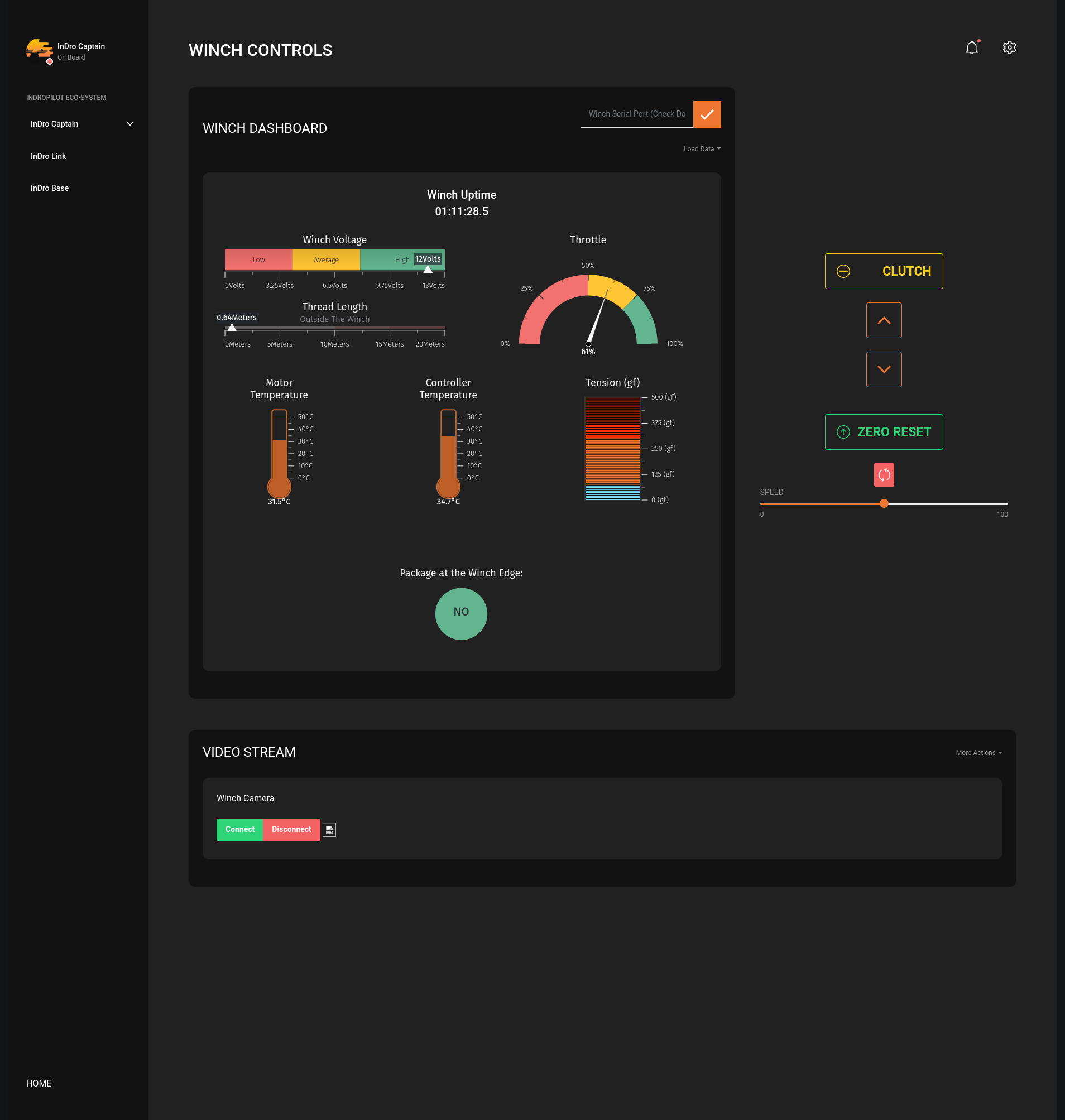

In some ways, that’s also what InDro Robotics does. As both a research and development company and an integrator, InDro frequently brings together disparate parts for a common purpose – most often, for special projects for clients.

“Everybody here is actually the perfect client for InDro,” says King.

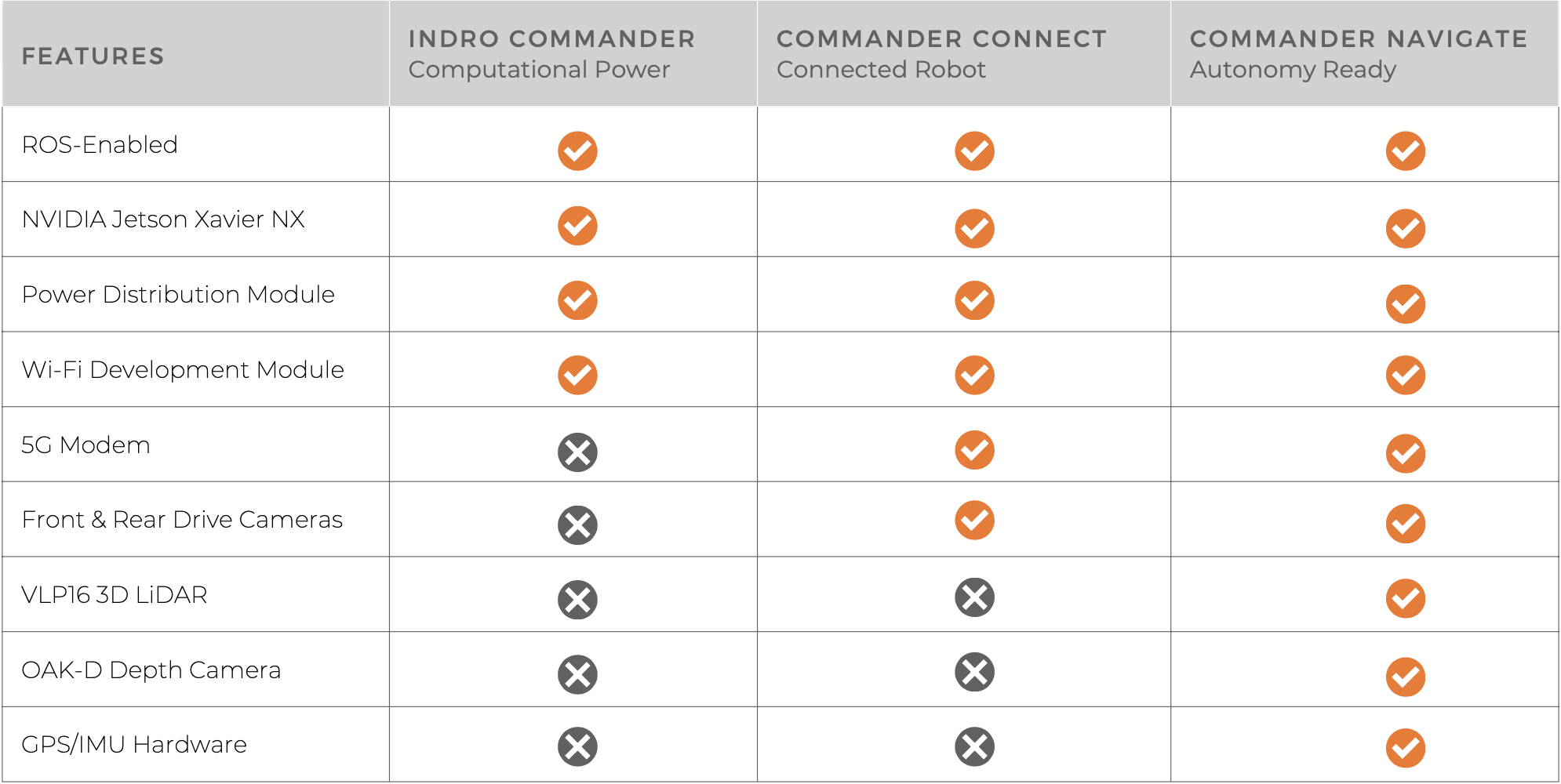

“Imagine you were studying autonomy and perception and you’re going to do this in ROS. These students and universities don’t have the budget or hardware or time to build what they need. So we can build a custom robot, generally outfitted with InDro Commander, so they can focus on simply coding their project.”

“It’s a very big international community – which I was not expecting,” adds Account Executive Amanda Gloor. “Plus, it’s great to see people showcasing technology from all over the world. One of the cooler things I saw was a robot that climbs storage tanks using magnets – then uses non-destructive testing to detect corrosion.”

Below: InDro Account Executive Amanda Gloor gets the Unitree GO2, which InDro distributes, to take a leap

POSTER EXHIBITS

If you’ve got the time (and the brains), the rotating poster exhibits are fascinating to dip into. There are some 1200 exhibitors either displaying their research or holding seminars. Some of that research could be the Next Big Thing, or a significant incremental advance that will be utilised in other applications.

A quick spin through just a few of the exhibits, during a session devoted to healthcare, revealed the following topics:

- A shared autonomous nursing robot assistant with dynamic workspace for versatile mobile manipulation

- Magnetic, modular, undulatory robot: Exploring fish-inspired swimming for advanced underwater locomotion and robotics

- Contactless weight estimation of human body and body parts for safe robotics-assisted casualty extraction

As you can see, some are highly specialised. Now think of hundreds (and hundreds) of such research papers, each making a small (or even large) contribution to pushing the robotics envelope. That’s IROS.

But while such important niche research was in abundance, there was also a sense that the Big Picture moving forward involves AI. While that’s always been a part of the robotics world, recent advances in artificial intelligence, machine learning and machine vision took centre stage. Many of the keynotes – and smaller learning sessions – focussed on AI.

Wednesday’s plenary session, for example, was “Merging Paths: The shared history and convergent future of AI and Robotics.” One of the keynotes was “Deep predictive learning in Robotics: Optimizing models for adaptive perception and action” – followed by: “Empowering robots with continuous space and time representations.” Those are in addition to scores of separate sessions during the conference with an emphasis on AI.

Instead of robots simply being aware of their surroundings and tasks, we appear to be heading into a world where these machines more fully understand the world around them, and make decisions based on that understanding. And that feels like a very big deal.

INDRO’S TAKE

There are always conferences going on in the robotics and UAV sectors. We could choose to attend all of them, but we tend to be selective.

For the academic and R&D world, IROS is the venue where we can learn about the latest cutting-edge research and technology – and display our own innovations (such as our new ROS-based indoor UAV, which has been gaining a lot of attention). So it’s good to be here again.

“The unique thing about InDro is our ability to have a conversation with virtually everyone at this conference,” says Luke Corbeth. “Given the scope of our work – whether it’s a new platform, or sensors, integration or production, there’s always some way we can be of value to those across the R&D community.”

It’s also a great place to meet the next generation of engineers and other specialists, some of whom may one day join the growing InDro team.