Elroy Air’s Chaparral brings long-range, heavy lift cargo solution

By Scott Simmie

Some history has just been made in the world of Advanced Air Mobility (AAM).

On November 12, Elroy Air successfully flew its Chaparral C1 – the first flight of a turbogenerator-hybrid electric vertical take-off and landing (hVTOL) aircraft. The hover test of the full-scale aircraft took place at the company’s test-flight facility in Byron, California.

It’s an important milestone as the world moves toward the AAM era, when new and transformative aircraft will move goods and people to destinations that would have been impractical or too expensive using traditional aircraft.

“This is an exhilarating day for our team and the industry as a whole,” says Elroy Air co-founder and CEO Dave Merrill.

There are plenty of companies competing for this new space with innovative autonomous designs. Some are designed to carry people, cargo, or both. There are several excellent designs out there, but Elroy Air’s Chaparral C1 has been on our radar for reasons you’re about to discover.

Before we get into the history, though, let’s get straight to the news. Here’s a video of the test flight:

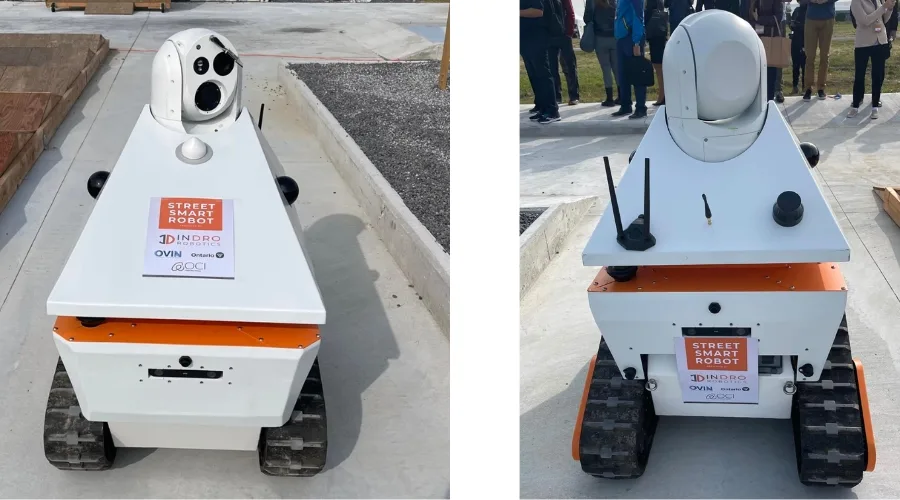

AND DOWN ON THE GROUND

Check out the Chaparral C1 on the ground. Take a good look, as we’ll be discussing these features.

THE CHAPARRAL

Let’s get into why this aircraft will fill a niche.

It’s been designed to move large payloads long distances – and do so efficiently. Humanitarian aid, military resupply and middle-mile logistics are all perfect use-cases for the Chaparral. Its sole purpose is to move significant amounts of cargo efficiently – and be ready for the return trip in minutes.

Here’s the one-floor elevator pitch:

“We’re building an aircraft that will be able to fly 300 miles (483 km) and carry 300 pounds (136 kg) of cargo,” explains Jason Chow, the company’s Director of Strategy and Business Development.

“It’s VTOL, so we don’t need runways. It’s also hybrid electric, so in many situations where there are remote areas, we’re still able to fly where electric power is unavailable.”

Hybrid electric makes sense when you’re after this kind of range, since the craft benefits from the energy density of jet fuel.

“A turboshaft engine powers the batteries, and the batteries power flight,” says Chow.

“One of the most intensive parts of flight is the takeoff portion, where you’re vertically flying upwards. And once you get into forward flight, the turbine is able to throttle back to meet the reduced demand while maintaining battery charge.”

As you can see from the photo, there are eight motors for vertical lift and four for forward propulsion. Once the craft transitions into forward flight, its fixed-wing design brings greater efficiency and range than would be possible with a traditional multi-rotor (which don’t generally have lifting surfaces aside from the rotors themselves).

But while all this looks great, Chaparral’s real secret sauce is its cargo capabilities – which have been designed, literally, from the ground up.

Take a look again at the photo above. Note the design of the wheel struts, as well as the ample space between the bottom of the fuselage and the ground. That’s all for a very specific reason: Chaparral has been designed to carry an aerodynamic, quickly-swappable cargo pod.

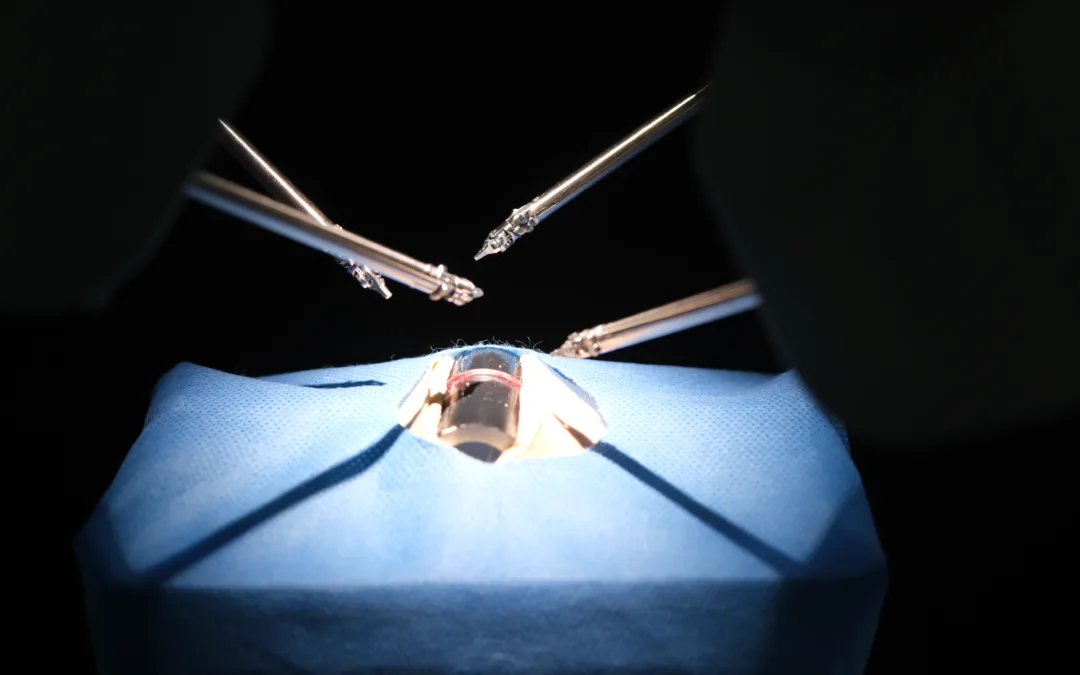

Have a look:

THE POD

Chow says the system is comparable to a tractor-trailer. On a road, the tractor provides the power to move the goods. In the air, “the trailer is the equivalent of the cargo pod. We imagine customers will have multiple cargo pods.”

Those pods can be quickly interchanged on the ground – because the Chaparral’s autonomy abilities aren’t limited to flight. The aircraft can taxi to a predetermined location, lower and disengage a cargo pod, then reposition itself and pick up the next one. You can imagine the advantage of such a system when transporting food or critical medical supplies in an emergency situation. This isn’t simply an aircraft: It’s a delivery system.

It’s also worth noting that the pod has been designed to be compatible with existing infrastructure and tools such as forklifts. As the Elroy Air website explains:

“The Palletized Pod uses a fairing-on-pallet design to ease loading of heavy cargo. This configuration features a standardized L-Track system for securing shipments, ensuring simple loading and safe travel for hefty items.”

Below: The Chaparral C1 with the pod snugged up and ready for business…

BUSINESS MODEL

So, will Elroy Air be a service provider, overseeing autonomous flights for clients? Or will it be producing the Chaparral to be sold to clients who will operate it themselves?

“The current thinking is that we would do both,” explains Chow. “There are a lot of our partners that are very good at operating aircraft: FedEx, Bristow, the United States Air Force. The main thing they do is operate aircraft really well. So in those situations we would sell to them only as the OEM (Original Equipment Manufacturer).”

“But we also have customers who are interested in what we can provide. So in those situations we could provide the service ourselves or rely on very experienced operators.”

MANUFACTURING

Producing an aircraft of this scale – it has a wingspan of 26.3 feet (8.01 metres) and a length of 19.3 feet (5.88 metres) – is no small task. Elroy Air made the decision early on that the most efficient approach would be as a highly selective and meticulous integrator. So its composite fuselage, for example, is outsourced.

“There are folks in the general Advanced Air Mobility industry that are building everything in-house. That’s great, you can own the IP (Intellectual Property) for everything,” says Chow.

“That being said, it takes longer. So our approach has been to be an integrator. We source the best parts to help us get to market – including the generator.”

TRAJECTORY

There are a lot of startups in this space, including plenty of newcomers. Elroy Air was formed back in 2016 in San Francisco by Dave Merrill (now CEO) and Clint Cope (Chief Product Officer).

By 2018 the company flight-tested sub-scale Chaparral aircraft and user-tested its automated cargo‑handling systems. The following year it had established a relationship (and contract) with the United States Air Force “enabling Elroy Air to understand and inform the USAF’s operational needs for distributed aerial logistics in contested environments. We developed our custom simulation environment for Chaparral aircraft and ran a successful flight test campaign on an early 1200‑pound, full-scale Chaparral prototype outfitted with an all-electric powertrain.”

The milestones have kept coming. The year 2020 brought refinements to its simulation system, allowing the team to carry out thousands of virtual flights and ground/cargo mission experiments. Development began in earnest that same year on the hybrid-electric powertrain, including multiple turboshaft engine runs.

A Series A financing in 2021 brought in partners Lockheed Martin, Prosperity7 and Marlinspike, who came to the table with $40M. In 2022 an additional $36M in capital arrived, and the company unveiled its C1-1 Chaparral to the public. (The aircraft also made it to the cover of Aviation Week.)

It’s been a careful, methodical journey that has brought the company this far – and it clearly has ambitious plans for the future. If you’d like to read about these milestones in greater detail, you’ll find a company timeline here.

But the biggest milestone so far? The flight that opened this story.

“This marks a major moment for the industry as hybrid-electric aircraft enable the dual benefits of runway-independent safe redundant propulsion, and long-range flight well in excess of battery power alone,” says co-founder and CEO Dave Merrill.

“Our accomplishment puts Elroy Air one step closer to delivering a transformative logistics capability to our customers and partners.”

INDRO’S TAKE

We at InDro obviously have a stake in the future of Advanced Air Mobility. We know from our own work in this field of the pent-up demand for efficient VTOL aircraft that can safely shuttle critical cargo – whether across major cities or to isolated communities lacking runways.

We’ve also been watching, with interest, the companies that are vying for space in this coming market.

“From everything we’ve seen, Chaparral is going to be a perfect fit,” says InDro Robotics President Philip Reece. “It’s cargo capacity and range will really fill a void, and the pod system – complete with its autonomous coupling and decoupling feature – will be hugely advantageous. We congratulate Elroy Air on this milestone, and look forward to seeing a transition flight before long.”

As with all new aircraft, it will take time before certification takes place and the FAA gives Elroy Air its full blessings. We’re confident that not only will that day come – but that Elroy Air and Chaparral will play a significant role in the era of Advanced Air Mobility.

All images supplied with permission by Elroy Air