Meet InDro Pilot: A powerful 5G hardware and software suite for Enterprise drones

By Scott Simmie

Nothing turns our crank quite like developing something brand new; something that’s never been done before. That’s really the heart and soul of R&D.

And that’s also why we’re so excited about InDro Pilot – a new hardware/software solution created by InDro Robotics that will give Enterprise drones and their operators the equivalent of superpowers.

Okay, perhaps there’s some slight hyperbole in that statement. But there’s no question that InDro Pilot will dramatically expand the capabilities of drones using the Pixhawk flight controller, the standard in many Open-Source drones.

InDro Pilot enables operations over 4G and 5G, meaning you could pilot a drone from across the country (providing you have a visual observer with eyes on the flight or a Beyond Visual Line of Sight Special Flight Operations Certificate). It also enables the secure transmission of even highly dense data (such as 4K streaming video) directly to the ground or the cloud with minimal latency. No more pulling out MicroSD cards and waiting for uploads. Realtime data, while you’re flying the mission, sent where it’s required.

Needless to say, this didn’t happen overnight. Getting here required an immense amount of effort from our Area X.O R&D facility. And, in particular, the project’s lead engineer Ahmad Tamimi – seen here on the right. When this photo was taken in the fall of 2021, Ahmad was in the thick of developing the 4K streaming component of the system and integrating it on our Wayfinder drone (foreground).

There’s a backstory here…

The catalyst for InDro Pilot was a technology challenge. The Ontario Centre for Innovation, in conjunction with Ericsson and the ENCQOR 5G testbed, put out a call to Canadian technology companies to enable drone flights over 5G. What’s more, the challenge required the successful transmission of uncompressed 4K video – which will help enable Beyond Visual Line of Sight flights because it provides the pilot with greater situational awareness. There were other bits and pieces, which we’ll explore at a later date. Point is, being the successful applicant in this technology challenge is what started us down the InDro Pilot road.

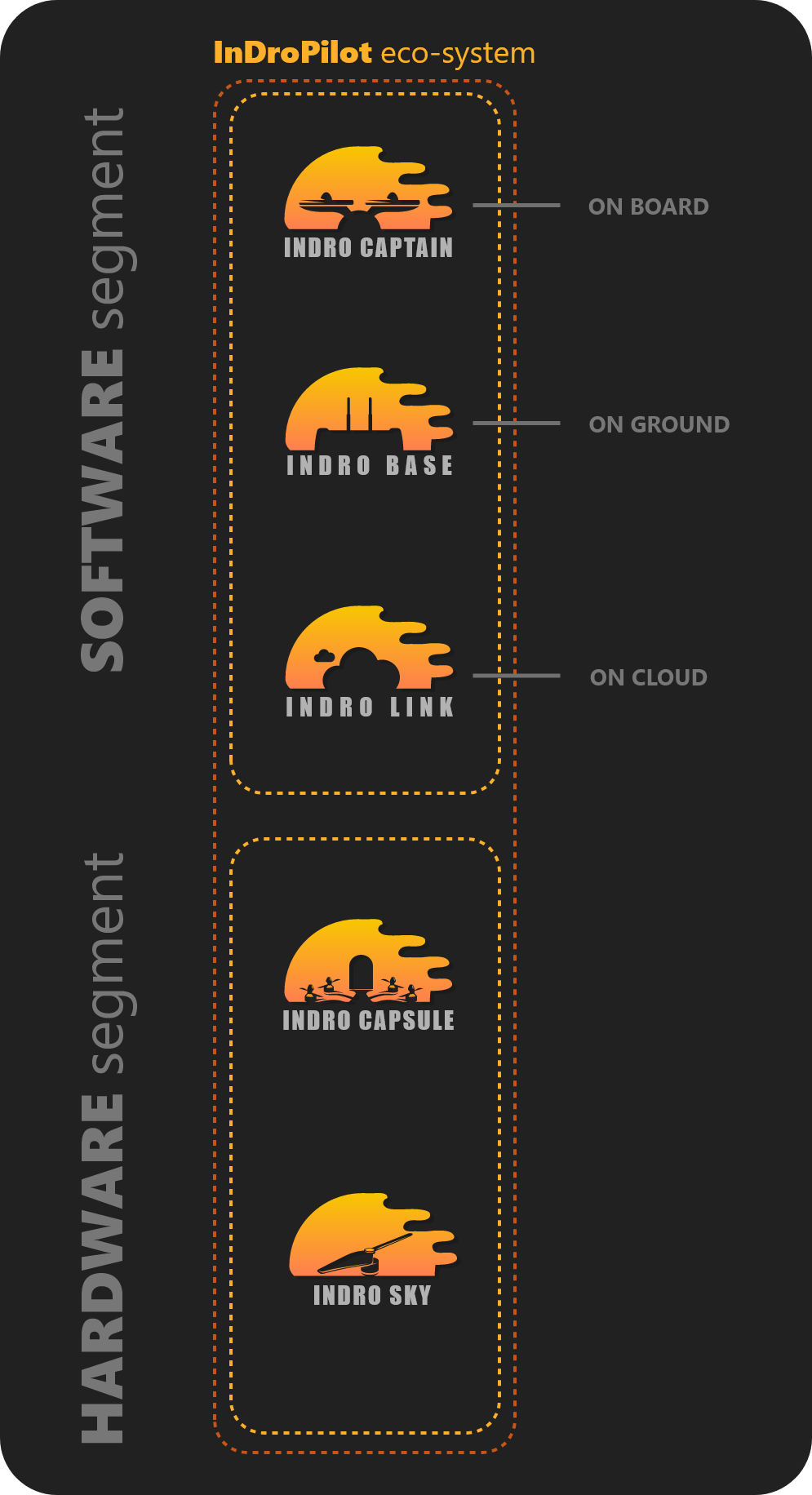

As we explain what InDro Pilot is all about, we’re going to get into a few names of various components. But big picture? It’s a combination of hardware and software that collectively brings about both enhanced capabilities for the drone itself (ie 4G, 5G, dense data realtime uploads etc.) as well as enhanced options for the drone operator to further customize drone sensors and peripherals for any given missions via dashboard.

Ahmad Tamimi pulled together this nifty graphic, which provides a high-level view of the system:

The basics

In this post, we’re going to focus on InDro Captain and InDro Capsule.

Let’s start with the latter.

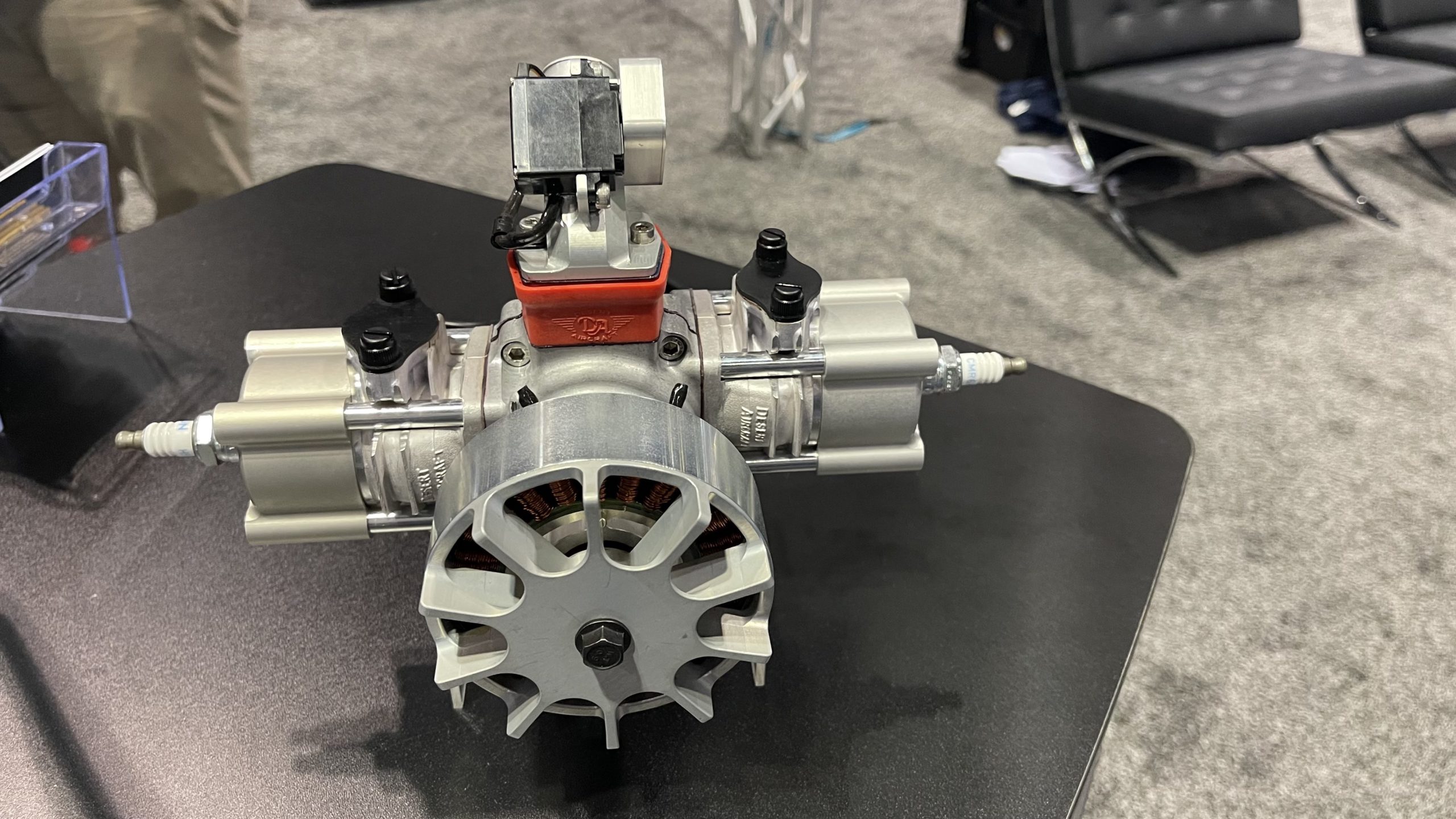

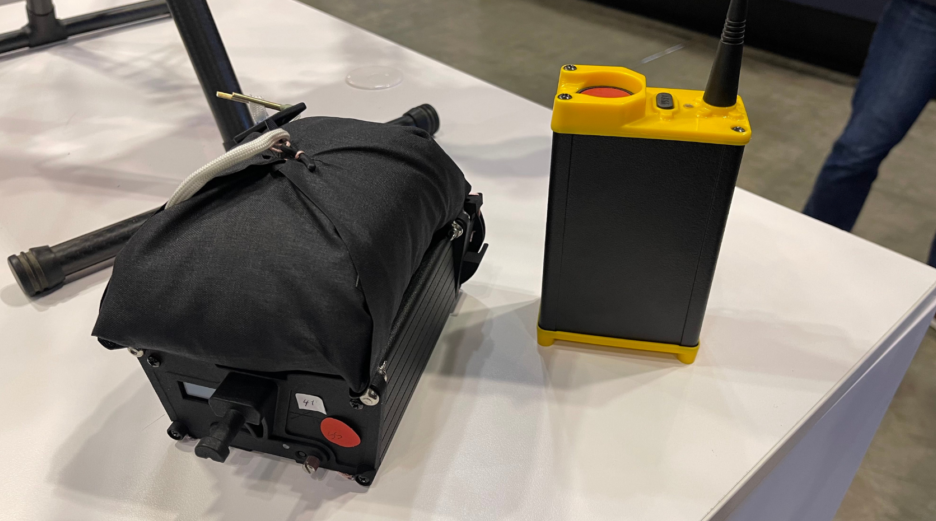

InDro Capsule is hardware, integrated into a capsule. Think of it as a box that can be easily attached to any Enterprise drone using a Pixhawk flight controller, because that’s what it is. That hardware includes:

- A high-speed Quectel modem for transmitting even dense data to the ground and the cloud in real-time

- A Jetson-based Edge processor

- Specialized antennae for both data transmission and Command and Control

- More IP-protected secret sauce we’ll unveil soon, which has significant implications for Detect and Avoid scenarios

InDro Captain, meanwhile, is the onboard software. It enables communication with the InDro Base (our ground station), secure data transmission to the ground or cloud, and can easily integrate peripherals like a winch or additional sensors.

And what does it look like? Well, the magic is contained within that hexagonal dome – and we’re currently making that dome smaller and lighter. Check out those wild antennae, chosen after a detailed calculations and simulations. And that white one with the InDro logo? We can’t wait to tell you what that one does.

Another look

These pix were taken during the R&D phase of InDro Pilot, so they’re just quick phone grabs. But we have a feeling you’ll probably like to see at least one more:

By the way, that’s a high-end mirrorless camera on that gimbal. With InDro Pilot on board, transmitting its uncompressed 4K output at minimal latency is a breeze.

When flying over 5G, the feed from this sensor (or any other) can be captured on the ground and simultaneously uploaded to the cloud. Our new InDro Link software (more on that later), securely integrates with third-party cloud services such as AWS, Azure, Google and more.

As 5G networks expand across North America and globally, this has significant implications for not only remote teleoperations and missions on private 5G networks, but also for realtime capturing of dense data. Providing there’s a 5G network at each end of the mission, a drone equipped with InDro Pilot can be controlled from across the country – with the pilot (and others) watching the data acquisition and all other aspects of any given mission in real-time.

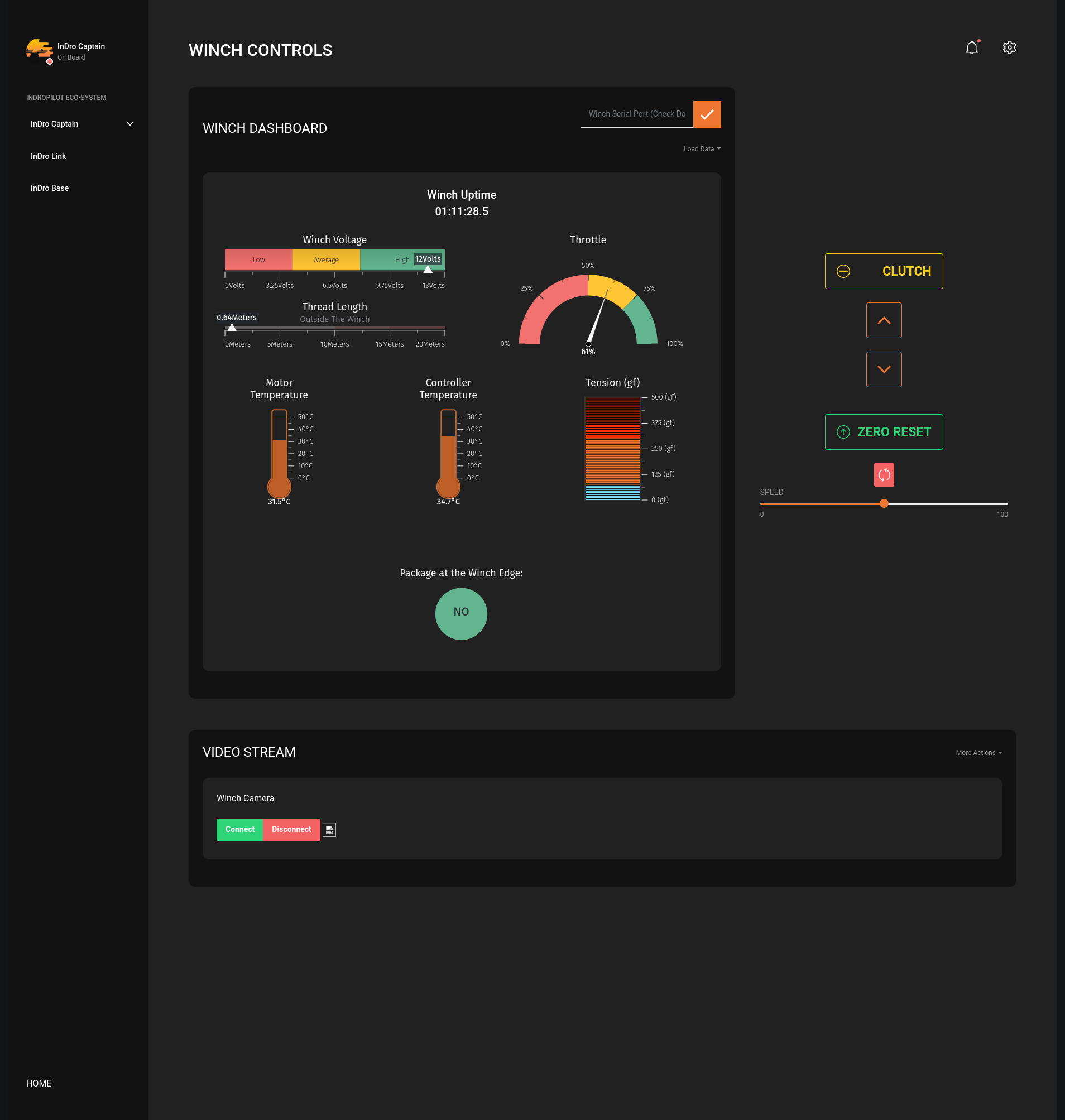

Interface

InDro Pilot is an entire ecosystem for 4G and 5G drone operations, including complex missions involving LiDAR, thermal sensors – even winches. The user interface reflects that, with “modules” (ie winch, etc.) that can be added to customize for each mission. Here’s a look at just one of many modules, offering granular control and at-a-glance monitoring.

“The InDro Pilot system is going to truly expand the capabilities of many Enterprise drones,” says InDro Robotics CEO Philip Reece. “Just as our InDro Commander module has made ground robots more powerful and customizable, InDro Pilot will do the same for UAVs.”

InDro Robotics has already delivered Wayfinder drones equipped with the InDro Pilot system to clients from the regulatory world. Commercial sales will commence shortly.

Interested in learning more? Feel free to contact Peter King.

InDro’s Take

As we said at the outset, nothing gets us revved up quite like creating new solutions. InDro Pilot has a myriad of powerful capabilities not outlined in this story – including some features that will definitely contribute to the safety of Beyond Visual Line of Sight flights though a proprietary system that will alert nearby private aircraft to the drone’s proximity during missions. So we’re excited about this product, much in the same way we were excited when we released InDro Commander for ground robots.

And while all Indro Robotics developments are team efforts, there’s often an individual who really takes the lead and owns the project. In this case, Ahmad Tamimi truly took charge, often working on it alone during those dark and early days of the global pandemic. InDro Pilot is a huge accomplishment, and we applaud Ahmad and the rest of the InDro team.

copyright 2022 © InDro Robotics all rights reserved