By Scott Simmie

We’ve just hired more bright people at InDro Robotics: Four engineers in total, with another one coming soon.

That’s a significant investment in our staff, and in our company. And while we’ll introduce a few of them here, this post isn’t really a “get to know you” story. It’s a broader narrative about growth, strategy and trajectory.

If you follow InDro Robotics (and presumably that’s why you’re here), you’ll know we’ve grown from a startup to a what’s known as an SME – a Small to Medium Enterprise. You’ll also know that our motto is: Invent, Enhance, Deploy.

That is, and will continue to be, our ethos. We invent our own products and market them – and build custom robots and drones for clients (including for some of the biggest technology companies on the planet). We also do highly specialised service provision and run the Drone and Advanced Robotics Testing and Training Zone (DARTT) at Area X.O, where clients can test robots on a course that meets the demanding criteria set out by NIST, the US-based National Institute of Standards and Technology. The drone section features a large netted enclosure, allowing operators to carry out training or even test drones with new technologies without the need for a Special Flight Operations Certificate from Transport Canada. It’s a very cool facility.

At our Area X.O engineering headquarters, we’ve grown from three engineers a little over three years ago to a staff of 20 (in addition to other operations elsewhere in Canada). Because so many components come into our shop – and so many robots go out – we have a full-time Supply Chain Manager and Logistics Coordinator. We have a Head of R&D Sales. And, of course, we have InDro Forge – a full-service rapid prototyping and limited production run facility that has every high-end fabrication tool you could think of (including a 3D printer capable of printing at volumes of up to one cubic metre).

It has been a steady and calculated growth trajectory so far, says Engineering Manager Aaron Griffiths:

“It’s been very strategical,” he explains. “We’ve been looking for robustness and longevity rather than speed.”

And – up until now – that growth has been reflective of our core tasks: Building custom products for clients and inventing our own products.

We’ve done that very well – and will continue to do so. But the long-term InDro roadmap has always included more. And we have now reached that stage.

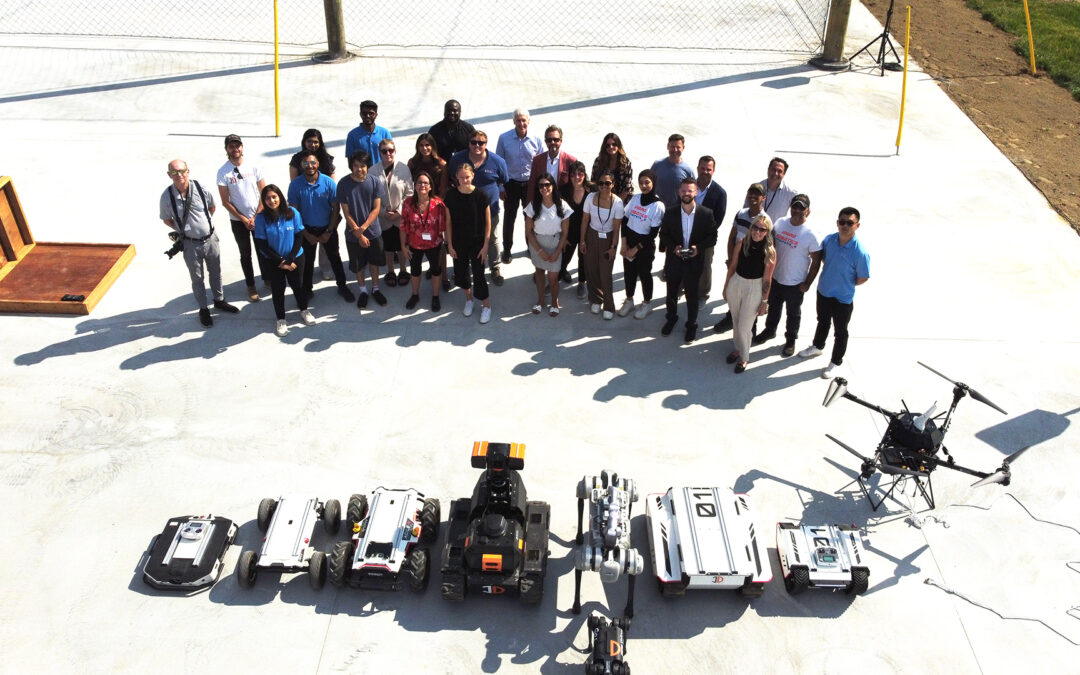

Below: Team InDro at the opening of DAART in June of 2023

INVENT, ENHANCE, MANUFACTURE

InDro has created some landmark products in recent years – with more to come. We can’t discuss all of them due to NDAs. But some public highlights that immediately come to mind include InDro Commander, InDro Pilot, InDro Controller, our Sentinel remote inspection robot, and much more.

Most of what was just mentioned are InDro innovations – meaning we have invented or developed these products with clients in mind, but not specifically as one-off projects. In other words, they have been built with an eye to actually producing and selling these products at scale.

Don’t get us wrong, we have certainly sold each of these products. But we’ve now reached a stage where demand – as planned – dictates that we expand in order to be able to run as a manufacturing facility while still retaining our ability to build custom robots and drones.

“If you want to turn out 10-20 robots over a few months, that requires a whole production team,” explains Griffiths. “That would be an additional five to 10 people just to do that kind of work.”

And not just a production team. As we continue to deploy more robots in the field, InDro now sees the need to start expanding our team to include Field Engineers.

“So you need a production team to make the things – and then a field engineering team to maintain and run them on client sites,” he adds.

FIELD ENGINEER

Our first Field Engineer hire is a familiar face to InDro. Liam Dwyer, who graduated from Queen’s University Canada in June of this year with a B.Sc. in Mechanical Engineering, previously carried out a 16-month co-op placement with InDro at Area X.O. But he’s heading into a very different role, suited to InDro’s growth.

“I’m going to be an on-site support and integration person to either get the client set up with the robot, supported with the robot, or to repair robots that may have been either damaged or just need maintenance,” he says.

He also recognizes the significance of his role in the bigger picture.

“I think the fact this title now exists at InDro really shows a lot of growth as a company. The fact there is now a full-time role to move and support these robots really means that the reach of InDro has gone pretty far – the name has gotten out.”

It’s also – both for Dwyer and InDro – a perfect fit.

“I’m a big fan of travel and I like field work, so I’m very excited for it,” he says. “It really puts a lot of emphasis on your individual ability to solve the problem and produce a solution. I was able to do some field work during my placement here, and I really like this kind of challenge.”

There are already plans for a second Field Engineer hire. And that’s on top of three other recent hires at InDro, including the highly experienced Steve Weaver in the senior position of Embedded System Engineer. He’s been in this space for some 25 years.

“Steve has been hired as a senior engineer for his wisdom,” says Griffiths. “He knows what to do and – just as important – knows what not to do.”

He’s joined by Nathan Sun, who has less long-term experience but has been working with all of the latest and greatest tools in AI and brings a fresh approach to things. Sun is also an Embedded Systems engineer, and should make the perfect work partner for Weaver.

“Nathan is the other side of the coin to Steve,” says Griffiths. “Together they’ll make a great team because they complement each other very well.”

That’s not all. Just prior to these three new hires, InDro also brought Sebastian Mocny on board in the role of Robotics Software Engineer. He’s currently busy taking Cypher Robotics‘ Captis cycle-counting AMR to the next level. InDro has an incubation agreement with Cypher Robotics, which also taps into the expertise and gear at InDro Forge. So that’s four engineers in short order, with more to come.

Below: New hire Liam Dwyer (R) during his co-op at Area X.O, with Tirth Gajera

BUILDING A TEAM

It’s been quite a voyage at Area X.O, with a lot of growth over the past few years. All of the hires go through Founder and CEO Philip Reece, as well as Vice President Peter King. But it’s generally Arron Griffiths who has to ultimately determine if prospective employees will be a fit for the Area X.O team culture InDro has worked so hard to foster (and where Griffiths works daily).

With a very low attrition rate and high job satisfaction, InDro is clearly selecting the right people – and building the right environment.

“It’s really all about personality,” say Griffiths. “It boils down to people’s mental state, their values. I would argue that if they’re driven, if they’re kind, if they’re a proactive learner, if they have empathy…the qualities you look for in a nice person are typically what you’ll find in a good and productive employee.”

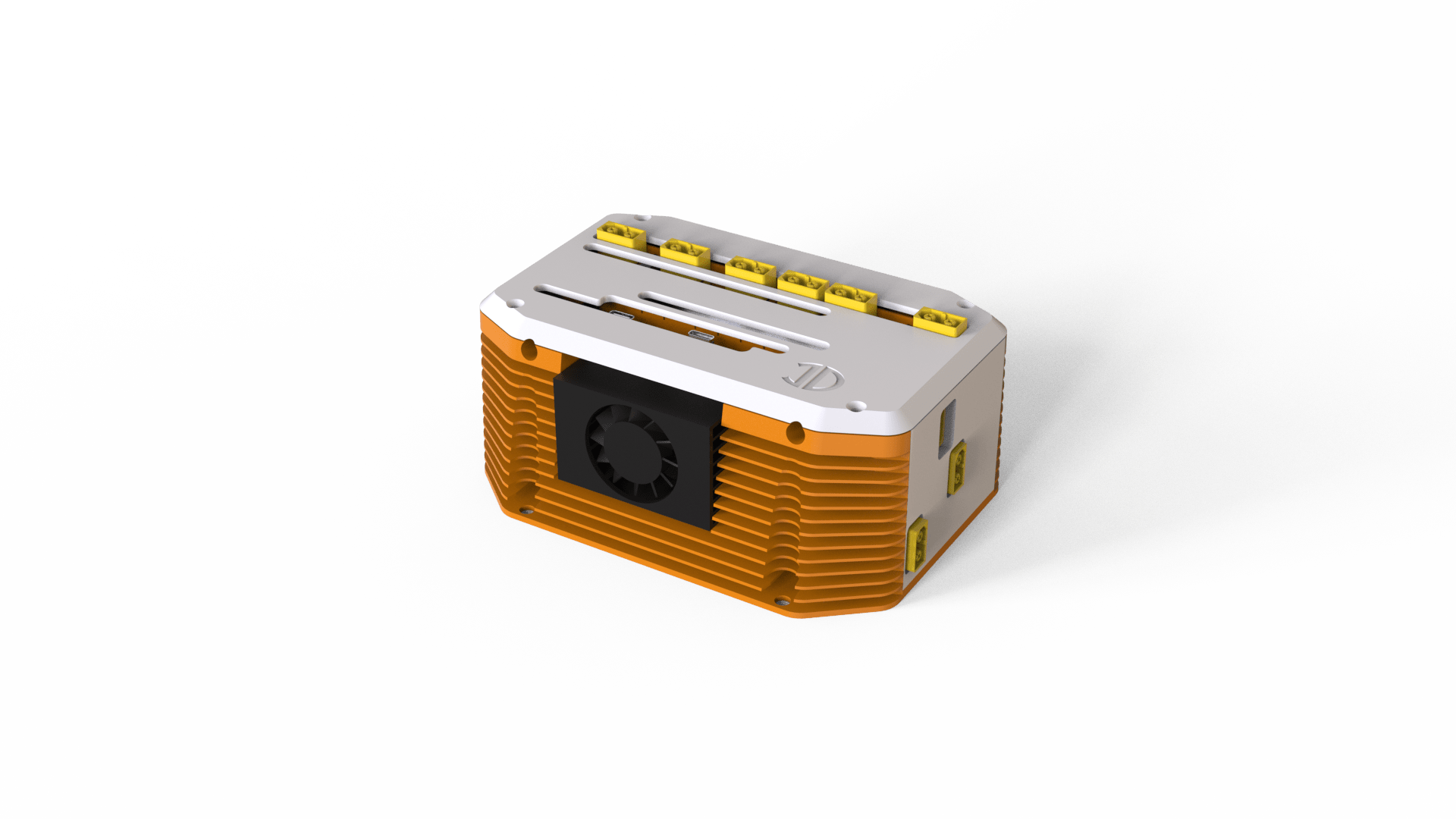

One of the big projects for next year will be the push to manufacture the recently-announced InDro Cortex. It’s a small but exceedingly powerful brain box for computer customisation that allows for rapid sensor integration and contains power management for multiple sensors along with ROS2 files. The Plug & Play (or Plug & Work) device follows on the incredible success of InDro Commander – and there’s already impressive demand. It also enables teleoperation and is the perfect match with InDro Controller – our intuitive dashboard for even highly complex autonomous missions.

And while we’re proud of the engineering work that has gone into Cortex, Griffiths says products like this “stand on the shoulder of giants” in the engineering world. And here, he’s referring to the tremendous advances in AI compute and other technologies that allow Area X.O engineers to truly work with the most advanced tools available.

“We have good and talented engineers,” explains Griffiths. “but we are definitely aware that other engineers out there have helped enable us to be on the leading edge of things. We’re hitting that very sweet spot in terms of technology maturity that’s enabling us to do this right.”

Below: InDro Cortex

INDRO’S TAKE

We’re obviously pleased to announce these four new hires – and to welcome these talented individuals to our team. We are equally proud to have reached a stage where we’re in the position and have the name recognition to forge ahead into manufacturing at greater scale. It’s a testament to the dedication of all of our employees – including administration, sales, logistics, marketing and management. (Oh yes, and content, too.)

“As we prepare to push into manufacturing and dedicated employees for onsite customer field support, I’m grateful to everyone for their hard work – and to our clients as well,” says InDro Robotics Founder and CEO Philip Reece.

“And to those clients who have relied on us in the past for custom solutions? Don’t worry. We’ll still be doing that with the same care and attention to detail. This simply marks a new expansion into manufacturing for InDro, which will continue to put significant resources into custom builds and R&D. Onward.”

Interested in exploring a solution from InDro? You can contact Head of R&D Sales Luke Corbeth right here. He’s incredibly knowledgeable and loves nothing more than helping clients find the perfect solution.