InDro Robotics, London Drugs, pilot Roll-E robot

By Scott Simmie, InDro Robotics

Meet Roll-E.

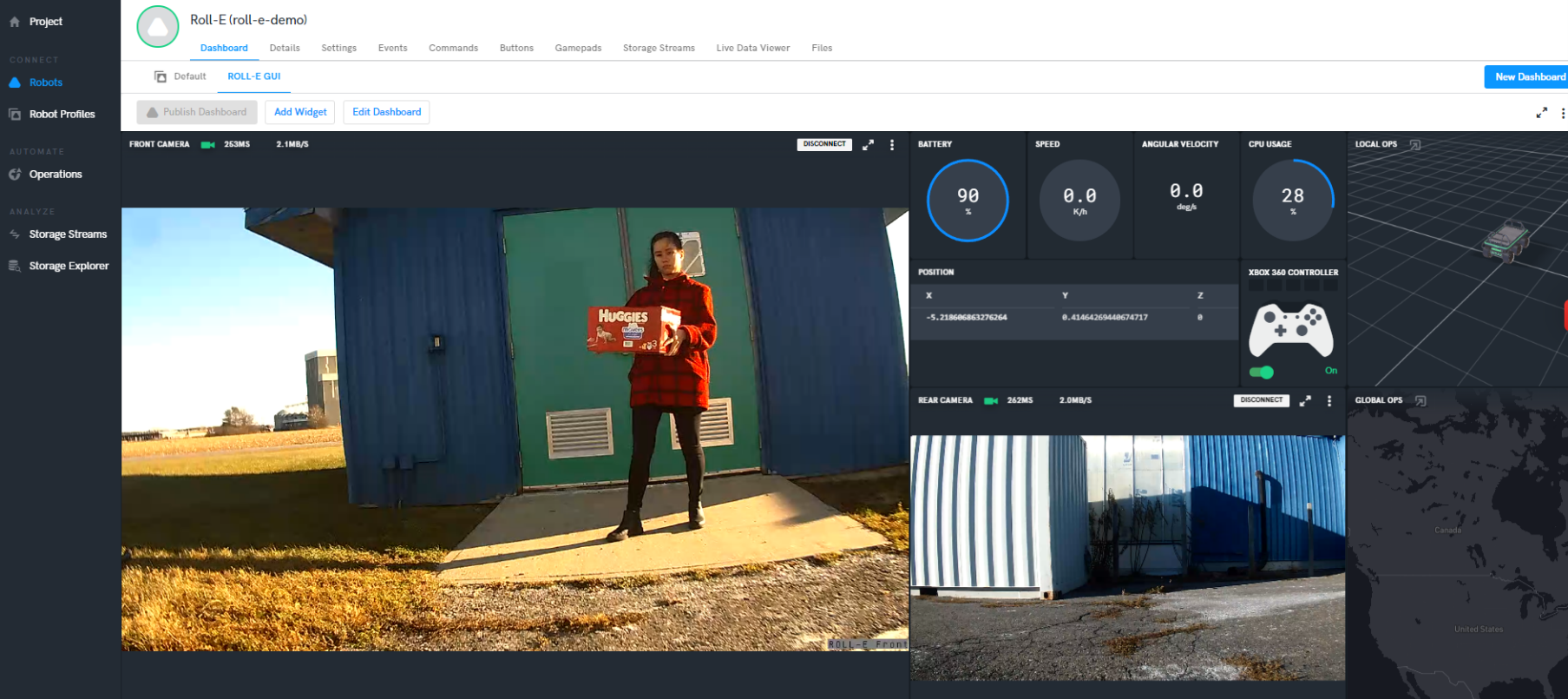

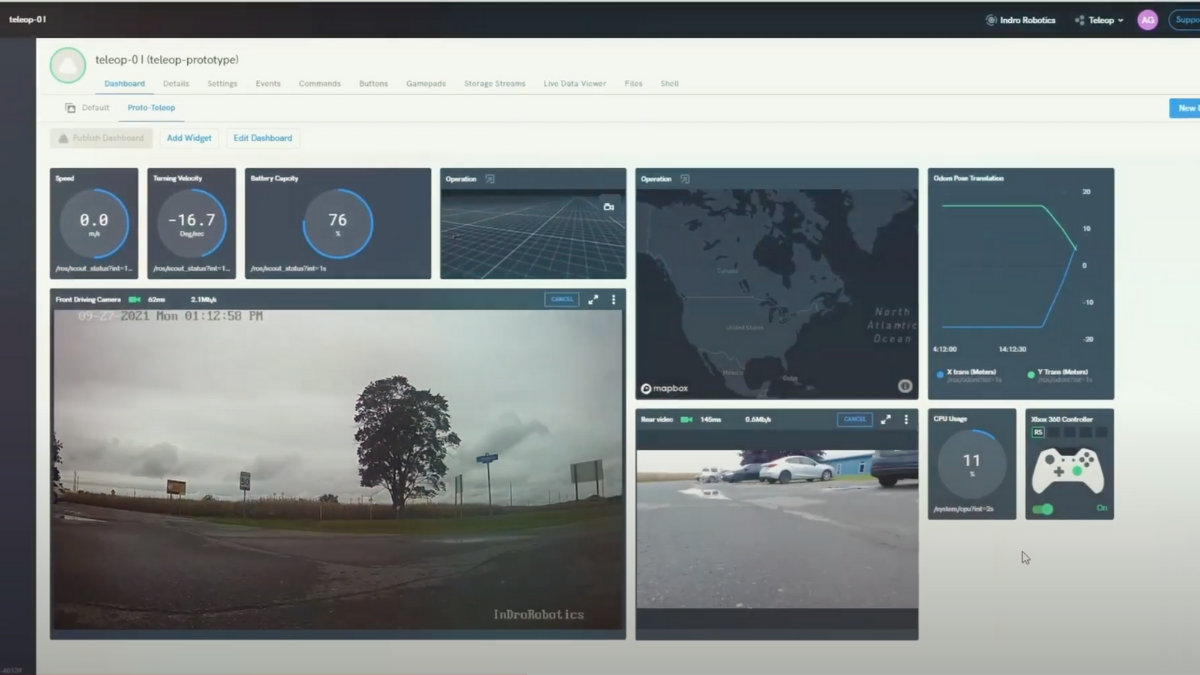

It’s a cargo-carrying Uncrewed Ground Vehicle (UGV), or robot, developed by InDro Robotics. It can be remotely teleoperated from around the corner or across the country. And it’s being put into service in a new partnership with London Drugs, helping with contactless curbside deliveries in Victoria.

We’ll explore all the relevant deets in a moment, but first – let’s take a look at this nifty and smart machine.

You’ve got to admit, that’s a pretty good-looking robot. But Roll-E is much more than that.

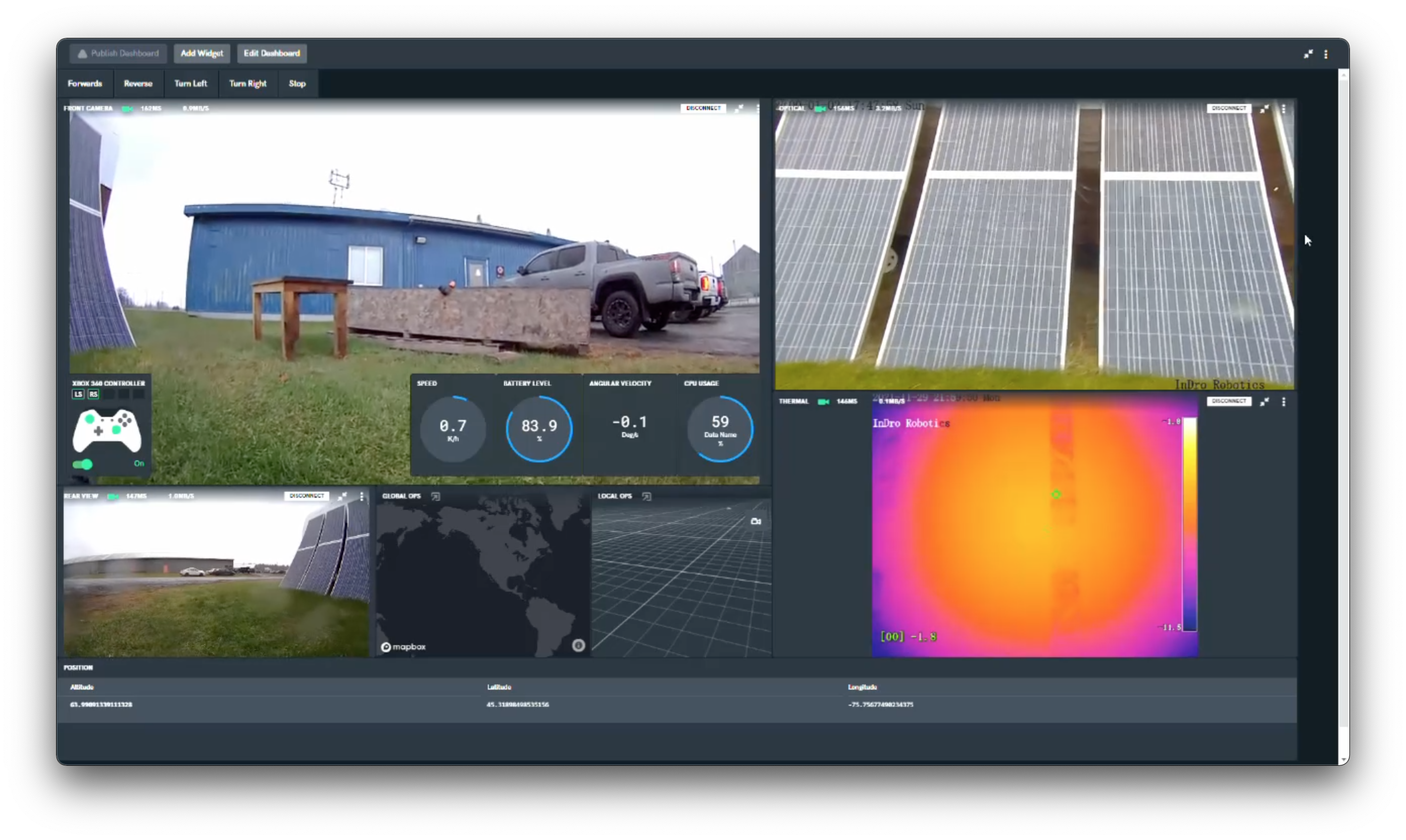

Built on the AgileX Scout Mini platform, Roll-E has been constructed to operate over the 5G and 4G networks. The remotely operated robot has a temperature-controlled cargo bay, GPS tracking, wireless charging – and turns on a dime. It also has front and rear cameras so that the operator can avoid any obstacles.

But what’s it doing at London Drugs? Glad you asked. Here’s the headline, from the London Drugs news release:

As we inexorably head into the Internet of Things universe, connected devices like Roll-E will play an ever-greater role in daily life. In this case, InDro Robotics has teamed up for an innovative pilot project at the London Drugs Harris Green Village location in Victoria, BC.

The global pandemic has changed, perhaps permanently, business and consumer practices. Online ordering and curbside pickups have grown tremendously. So we’re excited about using Roll-E to deliver secure, contactless pickup to drivers collecting goods.

And so is London Drugs:

“With the ubiquity of curbside pickup services now available, we’re constantly looking at new ways to invest and adopt cutting-edge solutions that will serve our customers in the safest, easiest and most user-friendly ways possible,” says Clint Mahlman, London Drugs president and COO. “We’re excited to pilot ROLL-E at our Harris Green Village store and further explore the full range of applications that this technology can add to our services in Victoria and at other locations throughout Western Canada.”

The UGV advantage

Though there’s a lot of potential for drone delivery (and more on this in a moment), current regulations make flying drones – particularly operating drones beyond the visual line of sight of the pilot in urban centres – difficult. The rules exist for very good reasons, including the protection of people, property and airspace.

Uncrewed Ground Vehicles are different. They operate on sidewalks or paths, not in airspace. The remote operator has a clear view of surroundings at all times, and pedestrians are given the right-of-way. InDro’s UGVs are all electrically powered, meaning zero emissions. InDro also received permission from Victoria’s municipal authorities, who are onboard with this pilot project.

This isn’t InDro’s first collaboration with London Drugs. In an earlier trial carried out in conjunction with Canada Post and Salt Spring Island’s Country Grocer, InDro demonstrated the ability to quickly and securely deliver prescription drugs to remote locations far faster than it would be possible to deliver via ground vehicles or by boat. Such aerial deliveries, especially in medical emergencies, could be life-saving. In that pilot project, drones were the appropriate tool because the locations were remote and did not involve congested urban airspace.

We’re still quite proud of that project, and you’ll see why here:

Roll-E’s a smart machine

Just as you can’t judge a book by its cover, you can’t judge robotic capabilities from the exterior. Roll-E contains the same brains as our proprietary InDro Commander module. This gives Roll-E the capability to eventually carry out fully autonomous missions, including mapping unfamiliar environments as it travels. Even machine learning and machine vision – where, for example, Roll-E is able to detect and act on the signals at a crosswalk – are all possible within this framework.

For now, though, Roll-E will be operated by a careful and conscientious human being working behind-the-scenes. Roll-E will be loaded inside the store for curbside delivery, then make its way to the appointed pick-up spot. It has a range of about nine kilometres on a single wireless charge, but Roll-E won’t be going far from home during this pilot project.

London Drugs has pulled together a great little Q&A, which you can find it here. If you’d like to see the entire news release, it’s here. (And if you’re really into this, you can check out CTV News coverage of the project.)

InDro’s Take

As an R&D company, we take considerable pride in the products we conceive, design and manufacture. It’s no different with Roll-E, which will help London Drugs customers at this particular Victoria location save time on pick-up. We also value our corporate partnerships – so we’re pleased to be taking part in this pilot project. We have a sense that for Roll-E, this is just the beginning.

“London Drugs has a track record of innovation, embracing new technologies that could help with efficiency and customer experience,” says Philip Reece, CEO of InDro Robotics. “We’ve enjoyed great success working with London Drugs and others on our drone trials delivering prescription medications to remote communities. I anticipate that someday in the future, deliveries using robots – whether by air or ground – will be routine.”

If your company might benefit from the use or robots or drones for delivery, inspection, security or data acquisition, don’t be shy. You can reach us here. (And no matter how advanced our technology gets, we’ll always ensure that a real person gets back to you.)