InDro partners with Montreal’s Chaac on landmine detection project

By Scott Simmie

On a recent day, small green pieces of plastic were scattered randomly across a road at Ottawa’s Area X.O.

They looked harmless. To a child, they might even look like a toy. But these are replicas of a Russian-made landmine known as the PFM-1. They are designed to maim, and will easily blow off a foot or hand if disturbed.

That’s what happened to a Ukrainian boy named Yaroslav in October of 2023. This UNICEF article outlines his injury – which took off the lower part of his right leg. Some children have been killed by these devices, which contain 37g (1.3 oz) of VS-6D or VS-60D liquid explosive.

The mines are banned by a 1997 agreement known as the Ottawa Convention or the Ottawa Treaty. But Russia, the United States and China did not sign the treaty. Ukraine ratified the convention in 2005, but in late June of 2025 issued a decree to withdraw from the agreement, stating that because Russia was deploying mines in the current conflict it had an unfair advantage.

Despite initially signing the agreement, in 2021 it was estimated Ukraine had a stockpile of 3.3M of the devices. Untold numbers of PFM-1s are scattered in the Ukrainian and Russian countryside, dispersed by planes or mortar. Their design allows them to spiral to the ground much like a maple seed.

“After years of war, Ukraine is now one of the most mine-contaminated countries in the world,” states the UNICEF article. “The ongoing fighting has left nearly a third of the country contaminated with landmines and other explosive ordnance, threatening the daily lives of children and families.”

And that, ultimately, is why these harmless replica mines – which look identical to the real thing – have been scattered at Area X.O. They’ve been placed to see if they can be identified and mapped autonomously for the purpose of destruction.

“There’s been a concerted effort by many to figure out a way to remove these from any former battlefield. So that’s why we’re involved with this project,” explains Maxime Phaneuf, Head of R&D with CHAAC technologies.

“We figured this would be a good use-case to try and do feature detection and to train a neural network to find them.”

Above: Chaac’s Maxime Phaneuf (R), with InDro Technologist Tirth Gajera, overseeing a demo. Below: One of the 3D-printed replica PFM-1s used in the project

THE PROJECT

The genesis for this project came from a request for proposals from Innovative Solutions Canada. The agency was looking for companies that could leverage technology for field detection – identifying objects of interest automatically. A Montreal-based company specialising in data, Chaac Technologies, was selected.

With a successful proposal, along with subsequent discussions with the Testing Department from the Department of National Defence, it was determined that a specific application – identifying PFM-1 mines – would be useful. And then Chaac got to work.

The goal was to create software, a neural network with embedded machine vision, that could identify these small devices on the ground automatically and with a high detection rate. Chaac got to work on the programming, but needed a partner with drone and ground robot expertise. The drone would be used to capture aerial photos.

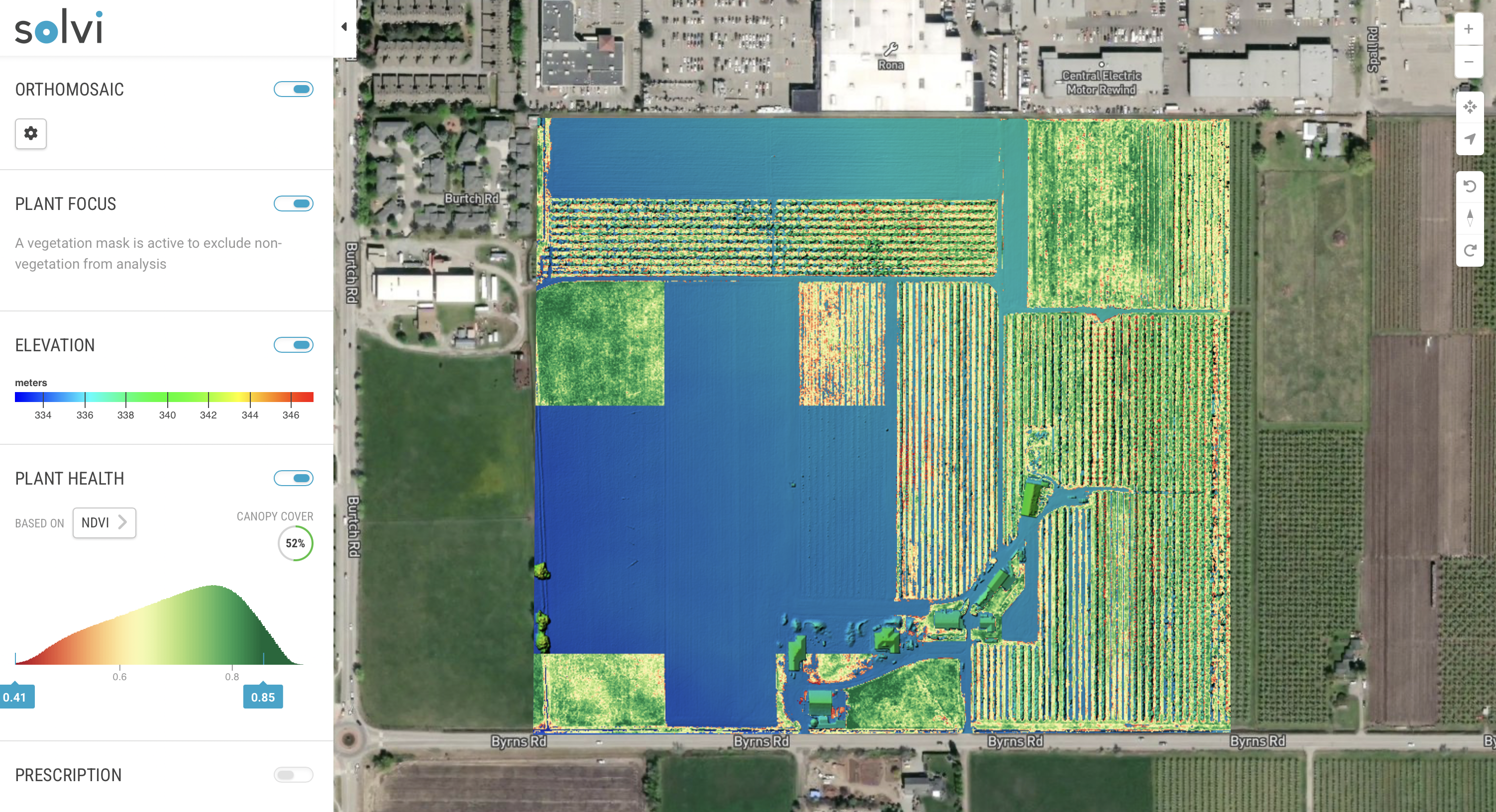

The Chaac software, which had been trained to identify PFM-1s by learning what they looked like in various positions on the ground, would automatically ingest those photographs and stitch them together into a single photogrammetric image. The software would then identify and mark each of those landmines on an orthomosaic – an image that’s geometrically corrected and georeferenced. The result is a map that highlights the location of each landmine, along with a score indicating how confident the neural network is that each feature is indeed a PFM-1. That data is then transferred to an InDro ground robot, which then autonomously navigates to each of the landmines.

“From drone to final map, it’s a fully automated workflow,” says Phaneuf. “That’s our innovation.”

Chaac has named the software SHIELDS – Secured Hazard Identification and Environmental Landmark Discovery System.

“We have a consistent detection rate of between 80 and 90 per cent,” explains Phaneuf. And while landmines are the focus, the software could be applied to any feature detection. “This particular system, we can use to discover any landmark as long as we train the neural network accordingly.”

Below: An InDro-modified drone autonomously captures data from above, sending it directly to Chaac’s neural network software for object identification and precision mapping. Our Sentinel inspection robot then confirms the data by autonomously driving to each detected PFM-1.

THE INDRO CONNECTION

The necessity for a drone and UGV (Uncrewed Ground Vehicle) is what brought Chaac to get in touch with InDro.

“One of the requirements of this project was to have Canadian-owned and operated hardware, not like DJI drones from China. And so we partnered with Indro,” says Phaneuf.

InDro built two Open-Source RTK drones operating with ROS2 (Robot Operating System), which will be delivered to the Department of National Defence as part of the contract. Our third-generation Sentinel UGV, also with RTK, is used as the ground robot. In a real-world deployment, the UGV could be used to detonate the mines, either by driving over them with a hardened shell, or with some other attachment that could trigger the devices.

And the next step for Chaac? Since the company has shown it can detect very small objects, Phaneuf anticipates DND might ask for detection of something else – say, vehicles for example. Chaac hopes its PFM-1 SHIELDS detection system will make it into the real world.

“I would be very happy if we can save some lives with this project and deploy it in in the Ukraine, or maybe after the war in Russia,” says Phaneuf. “We have hopes that this project will bear fruit and can be deployed in an actual combat or post-battlefield situation.”

We share that view.

Below: Chaac CEO Guillaume Nepveu explains the project during a recent episode of our Sound Byte micro-podcast

INDRO’S TAKE

We are pleased to have been brought in as a partner by Chaac on this project. As an R&D company specialising in UGVs and UAVs, it was a perfect fit. We also applaud the use-case, and hope Chaac’s SHIELDS system can one day be used to detect and destroy PFM-1s or other surface landmines.

“Landmines, sadly, continue to pose a threat to soldiers and civilians in many parts of the world,” says InDro Founder and CEO Philip Reece. “There’s no question technology can be, and has been, used to great effect to neutralise this threat. Chaac’s machine vision/neural network approach is a perfect example of combining cutting-edge software and hardware together with a single and positive goal. We look forward to seeing the next steps.”

We’ll keep you updated.