Bipedal robots step into the scene

By Scott Simmie

There’s been a lot of buzz over bipedal robots in recent years.

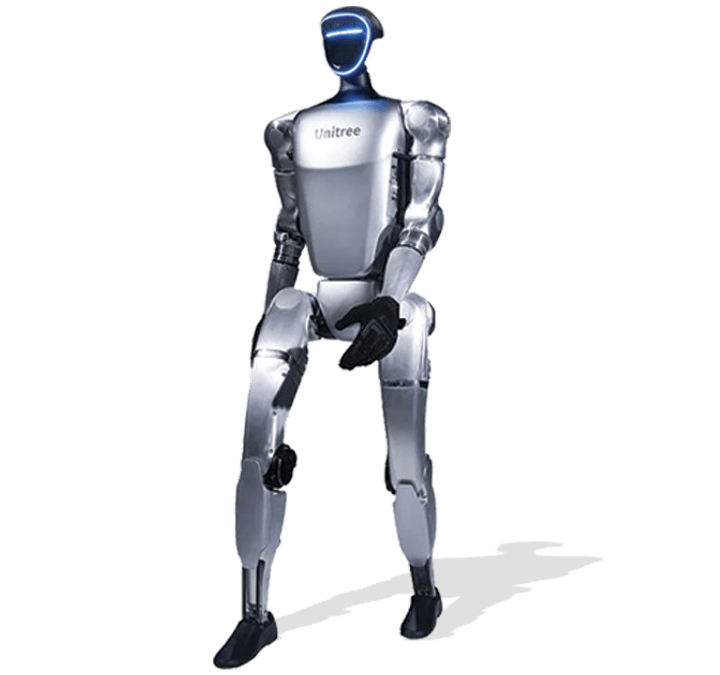

Companies like Boston Dynamics, Agility Robotics, Unitree and others have developed powerful algorithms and leading edge hardware to make what was once science fiction a reality. There are now an increasing number of walking (and sometimes talking) upright robots that get around on two legs. These tend to be humanoids, but they are bipedal.

There’s a certain cool factor to seeing robots that walk like people. But the push for bipedal robots is also driven by infrastructure: Factories and other settings where such devices might be deployed have been built for people. So robots that can walk and are roughly human size can work in such spaces without infrastructure changes.

“With the automobile, we had to build roads,” said Jonathan Hurst, Chief Technology Officer of Agility Robotics, in an explanatory video. “With legged robots we’ve already built the infrastructure. Legged robots are going to change the world as much as the automobile did.”

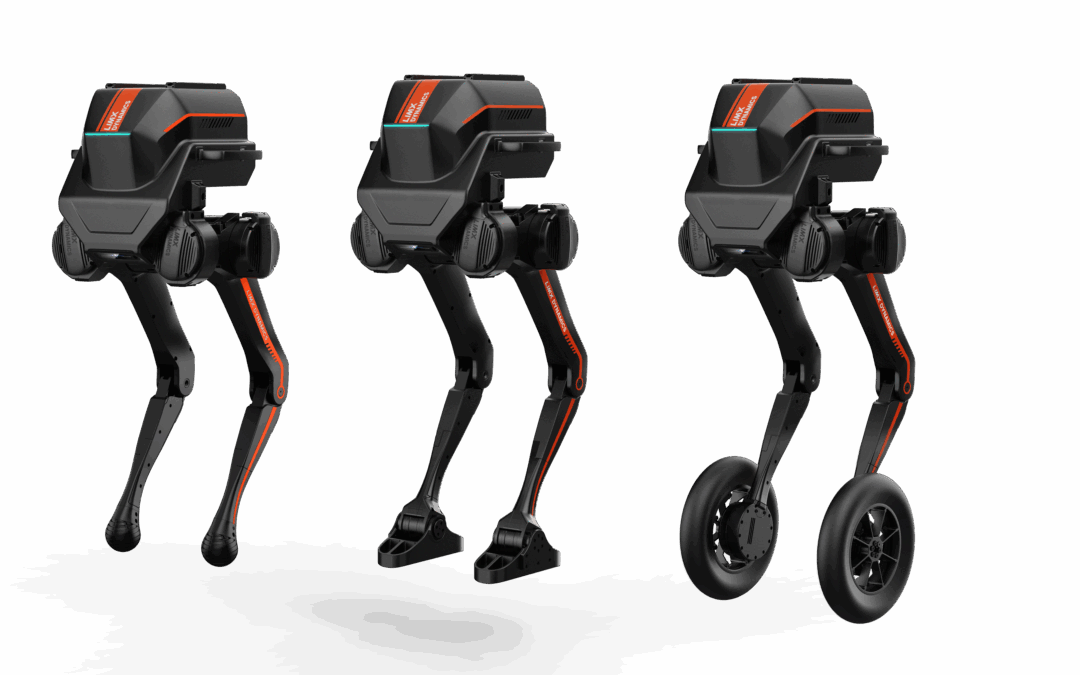

As the saying goes, time will tell. But before we proceed, it’s worth mentioning that bipedal doesn’t necessarily mean humanoid.

“A humanoid typically mimics the human form – so it has a head, torso, arms and legs,” explains Luke Corbeth, InDro’s Head of R&D Sales.

“Bipedal simply means it walks on two legs, but it doesn’t need to look human. So while most humanoids are bipedal, not all bipedal robots are humanoids.”

Below: Agility’s Cassie – a bipedal, non-humanoid robot. Immense R&D went into developing this machine, with many of the lessons learned applied to its current Digit humanoid

THE BIPEDAL-HUMANOID CONNECTION

As the video illustrated, bipedal robots aren’t necessarily humanoid (though they can be). But since the non-humanoid versions don’t have arms or manipulators, what are the use-cases?

First off, they’re critical tools in the R&D space. Before any company attempts a full-blown humanoid, it needs to perfect locomotion, balance and gait. That, of course, requires intensive hardware and software development. Many in the research space don’t have the time or resources to build from scratch. By starting with an existing bipedal robot they can rapidly start working on improving algorithms, adding autonomy stacks, machine vision, etc.

“Achieving stable and efficient bipedal locomotion is really the first critical milestone – so it involves doing things like balancing the gait, being very energy efficient and knowing how to recover from various disturbances,” says Corbeth. “But once that’s dialed in, you can build advanced capabilities on top of it, things like manipulation or autonomous navigation. So starting with a bipedal platform can help clients achieve their ultimate goals much sooner”

Not surprisingly, clients for bipedal, non-humanoid platforms are often in the R&D space.

“For anyone specifically researching bipedal locomotion, these devices make sense,” he adds. “It allows them to really focus on research and control, computer vision and AI applications. It’s an accessible platform for labs to really accelerate their work on humanoids.”

In other words, perfecting a bipedal platform is critical in the development of full humanoid robots.

RISE OF THE HUMANOIDS

We recently took a dive into humanoids here.

To recap briefly, humanoids are on the rise because their form factor allows them to integrate with existing infrastructure. With arms and manipulators/end effectors, they can carry out many of the tasks that humans perform. Bipedal design means they can climb stairs or navigate other obstacles. Even humanoids with wheels or tracks can now carry out these manoeuvres.

“Humanoid robots have become one of the most frontier topics in the field of robot research [1],” states this research paper. “Owing to the human-like structures and strong environmental adaptability [2], biped robots can directly operate the tools and vehicles used by humans, showing wide application prospects in fields such as home service, industrial manufacturing and environmental detection [3]…Ongoing research…shows great potential in human–robot collaboration and autonomous operation [6].”

Many of the tasks bipedal robots will eventually carry out aren’t even fully known yet, as these new commercial products are very much – despite some really impressive machines – in the early stages of adoption and deployment. It’s a safe bet that every company currently selling bipedal or humanoid robots is hard at work in the lab on the next generation. There’s a lot of development in the pipeline.

We hit up AI for some thoughts on where these machines are going. It concurs that the full benefits of bipedal robots have yet to be realised.

“While bipedal robots offer unique advantages, it’s worth noting that they are still under development, and their efficiency and practicality in certain applications are still being evaluated. For example, wheeled robots might be more energy-efficient for certain tasks on flat surfaces. However, for navigating complex, unstructured environments and interacting with human-scale tools and spaces, bipedal robots offer a promising solution.”

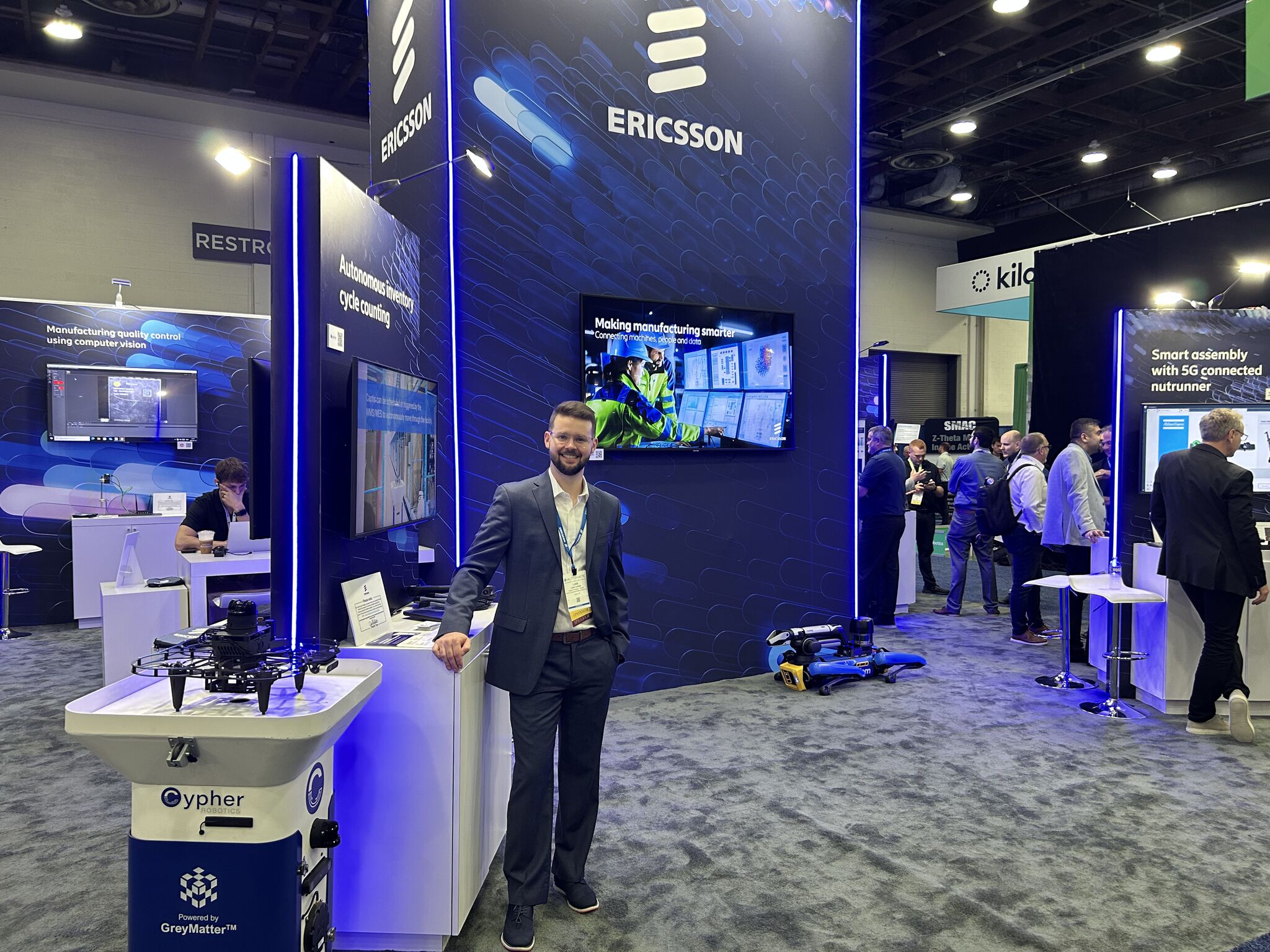

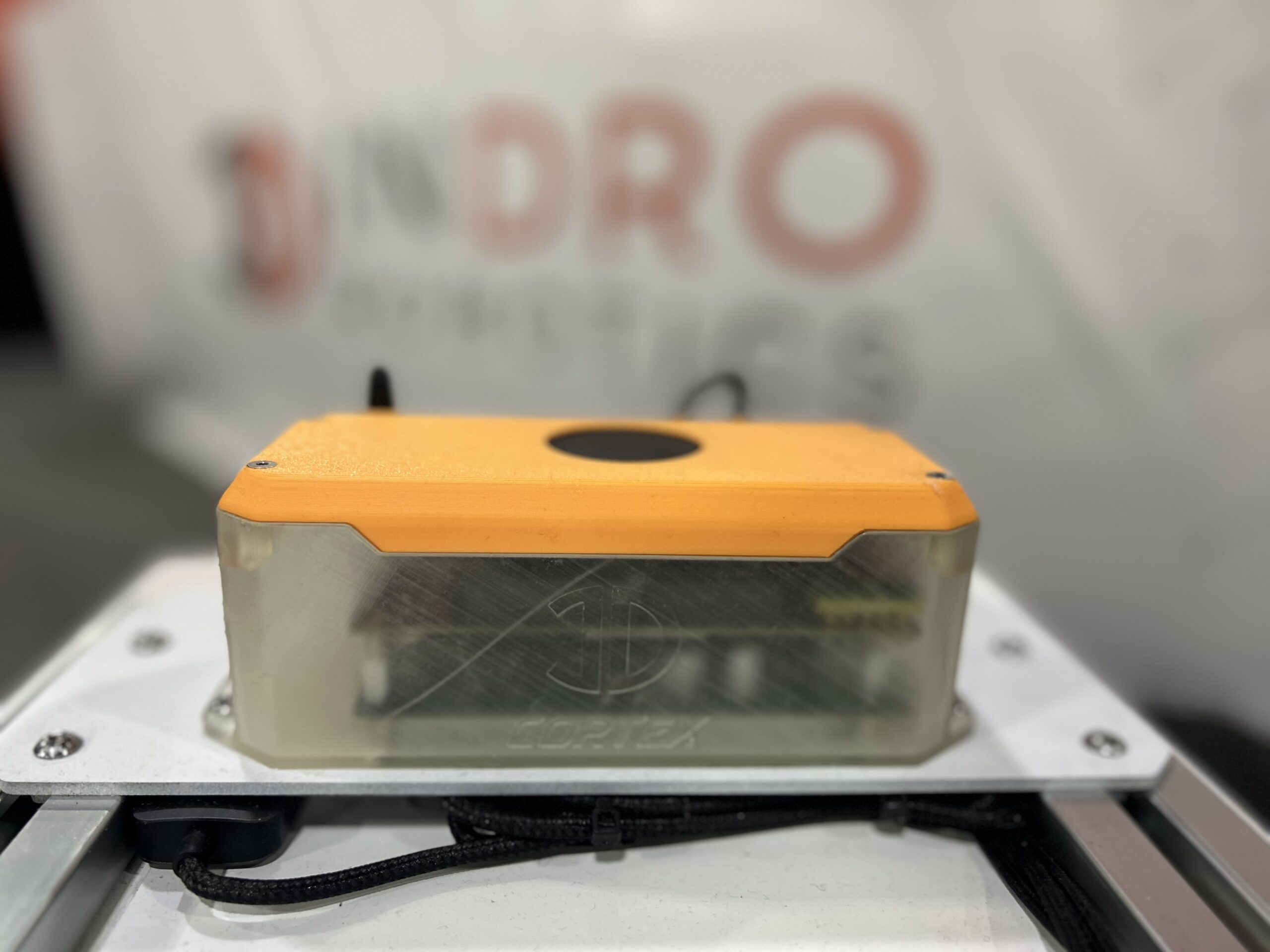

In addition to humanoids, InDro now offers a strictly bipedal, non-humanoid platform primarily for R&D. As with most platforms, our engineers are currently working on expanding its capabilities to enable it more fully for R&D and industrial clients. We will soon be integrating InDro Cortex, a brain-box that enables everything from remote teleoperation and sensor integration to fully autonomous and/or easily programmable missions.

“We’re looking to add our Cortex solution – the hardware and the software and the autonomy – to our humanoids and bipedal robots,” says Corbeth. “We see opportunities to integrate advanced autonomy, teleoperation and perception pipelines into this equipment…making them a turnkey solution for advanced humanoid development and real-world testing.”

Below: A great video explanation of the bipedal advantage, followed by the bipedal robot InDro now has available

INDRO’S TAKE

Bipedal robots are the precursor to full-blown humanoids. Not only does the humanoid form factor work well in existing infrastructure, they’re seen by many as the ideal collaborative robots, or co-bots. People seem more at ease with something that looks vaguely human (with the notable exception of Terminator’s T800).

“The human form factor is just intuitive for people to interact with – and the similar size helps them use human tools and really fit in well in workspaces,” says Corbeth. “Some may argue as well they also kind of build trust, which is crucial for collaborative robots operating around or with people.”

And for those in the R&D space looking for a bipedal-only platform, we’ve got you covered.

We look forward to sharing more about our bipedal and humanoid robots in future, particularly once we’ve supercharged them with InDro Cortex. If you’re curious to learn more, feel free to contact Luke Corbeth.