Rogers speaks with InDro CEO Philip Reece

By Scott Simmie, InDro Robotics

Rogers Communications, as you likely are aware, is a leading Canadian telecommunications and media company. Many of us watch television, cruise the internet, text and make phone calls using Rogers systems.

It’s also a leader in the world of 5G networks, which bring a quantum leap in wireless data transmission bandwidth. You can pump a lot of data via 5G, which opens up a lot of new opportunities for technologies like drones. For example, you could transmit crystal-clear 4K video with a drone over 5G. (We’ve already done it.)

What you might not be aware of is that InDro Robotics has partnered with Rogers on a number of projects involving flying drones over its 5G network, and transmitting real-time data back to the ground. InDro sees 5G as something of an inflection point in the world of drones and robots, paving the way for critical missions – even missions that are operated from hundreds or thousands of kilometres away.

A chat with Philip Reece

Because 5G and drones are going to be a big deal, Rogers had one of the writers from its business blog get in touch with InDro CEO Philip Reece. Specifically, they wanted to ask Philip to describe three cutting-edge uses of drone technology.

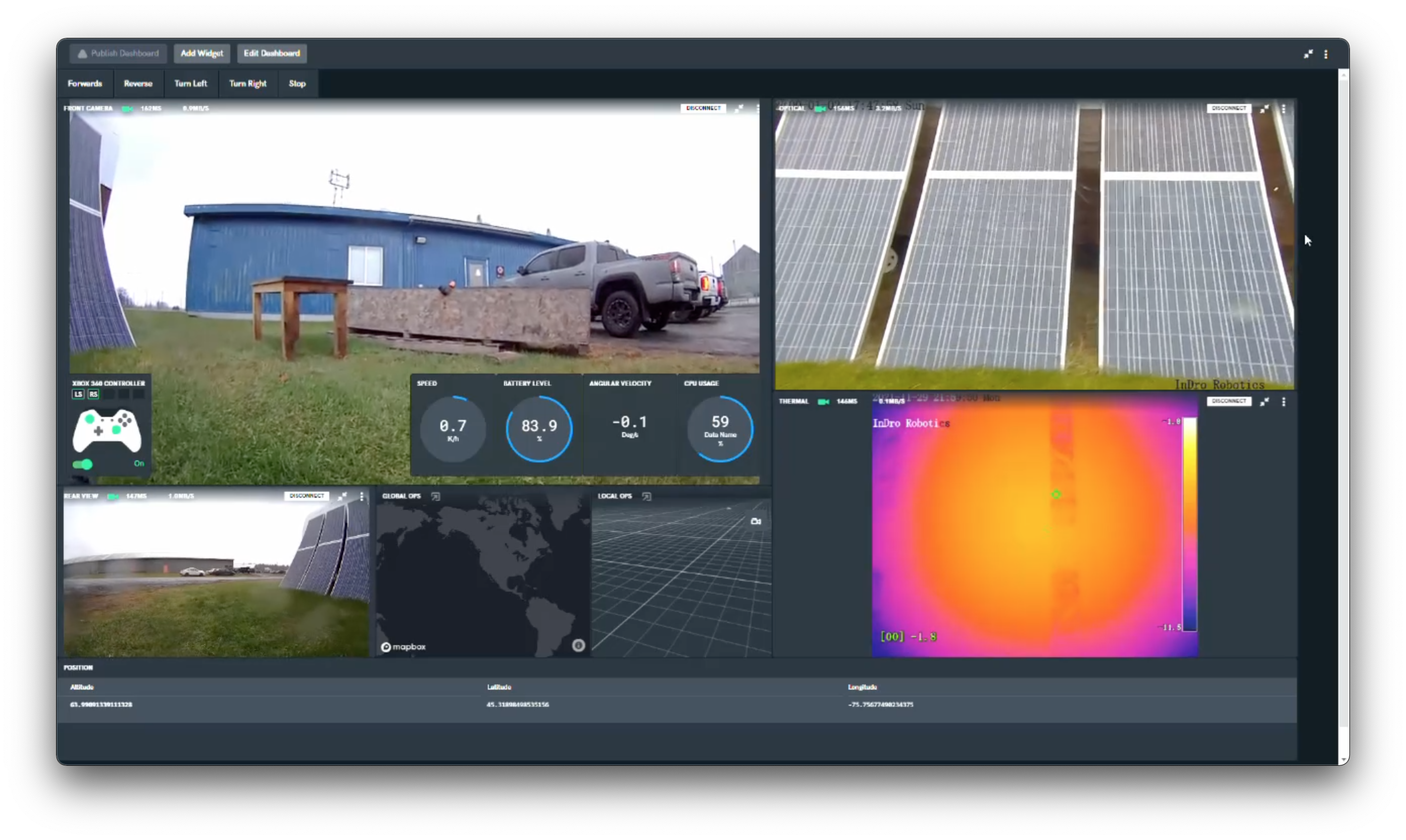

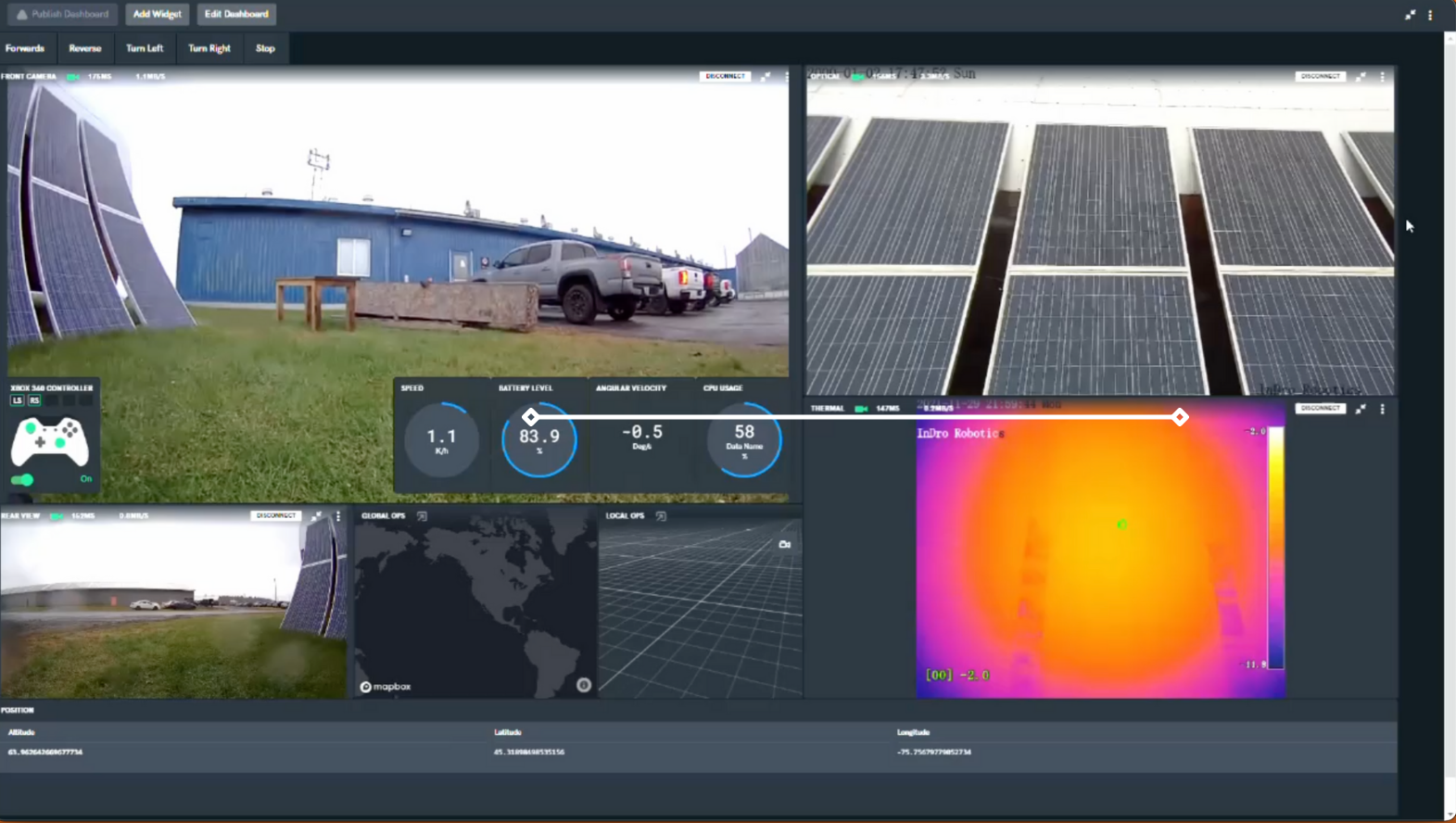

That’s a good question. And Philip was ready with some answers, which now appear on the Rogers For Business blog. Here’s a screen grab from the article:

The three examples…

It’s a good thing Philip (pictured here) was asked for only three examples, because 5G opens the door to a lot of new innovative and positive uses of drones. (InDro, if you weren’t aware, has always been interested in putting drones and robots to work doing good things.)

We don’t want to give away too much from that Rogers blog, but we will flag these three cutting-edge use-cases that Philip explores in greater detail:

- Delivering urgent medical aid

- Flying from public to private networks

- Capturing critical data for First Responders

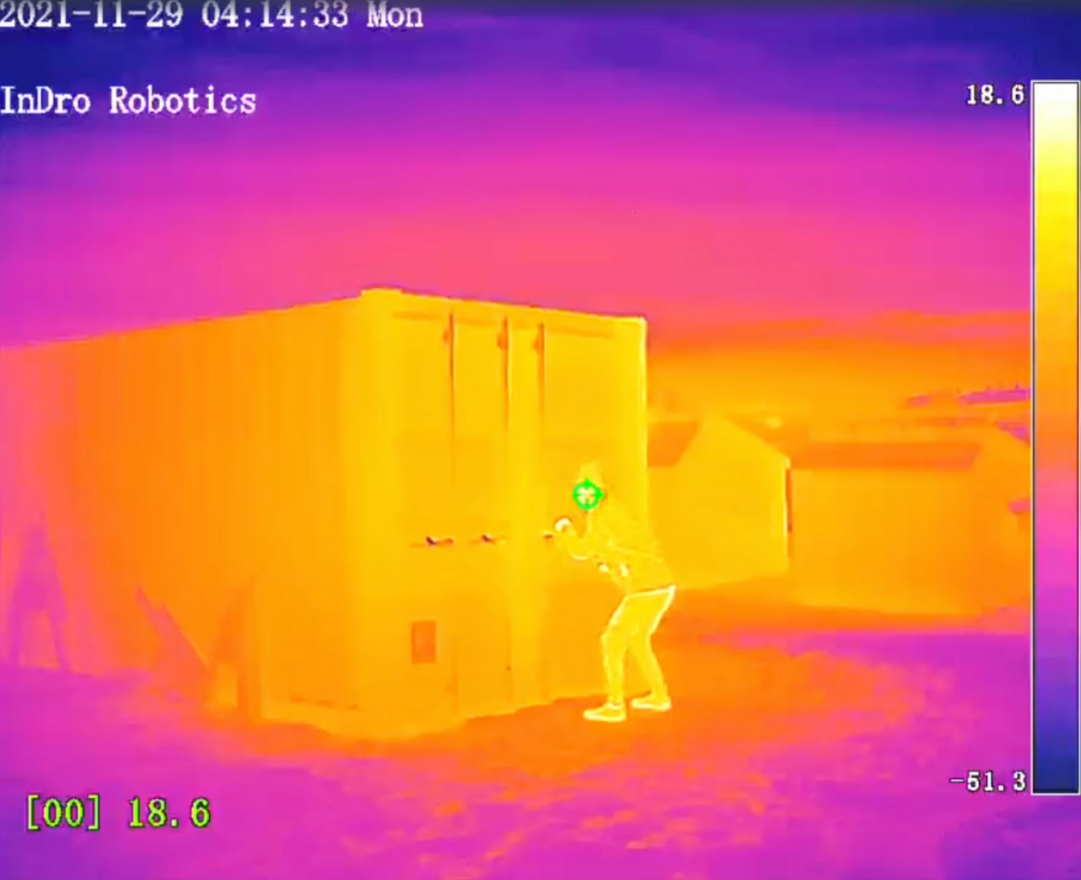

In each of the above examples, 5G plays a role in tremendously expanding the capabilities of drones. With First Responders, for example, a drone could be remotely operated over an incident by an InDro pilot – providing Responders with instant situational awareness, allowing them to focus on the task at hand instead of flying drones.

Check it out…

There’s much more, of course, and Rogers captured it very well. It’s a really worthwhile read, and you can find it right here.