InDro Robotics tapped to fly drone missions at Kelowna fire

By Scott Simmie

As forest fires continue to threaten Kelowna, BC, officials have urged tens of thousands of residents to heed warnings and evacuate from the area. Some 30,000 people are currently under an evacuation order, with another 36,000 being told to stand by and be ready to flee if necessary.

“We cannot stress strongly enough how critical it is to follow evacuation orders when they are issued,” said BC minister of Emergency Management Bowinn Ma on Saturday. “They are a matter of life and death not only for the people in those properties, but also for the first responders who will often go back to try to implore people to leave.”

Now, the City of Kelowna has called on InDro Robotics to assist with the effort by flying drone missions to gather specific data.

Recent footage shows just how close the fire is to the city:

INDRO TO ASSIST

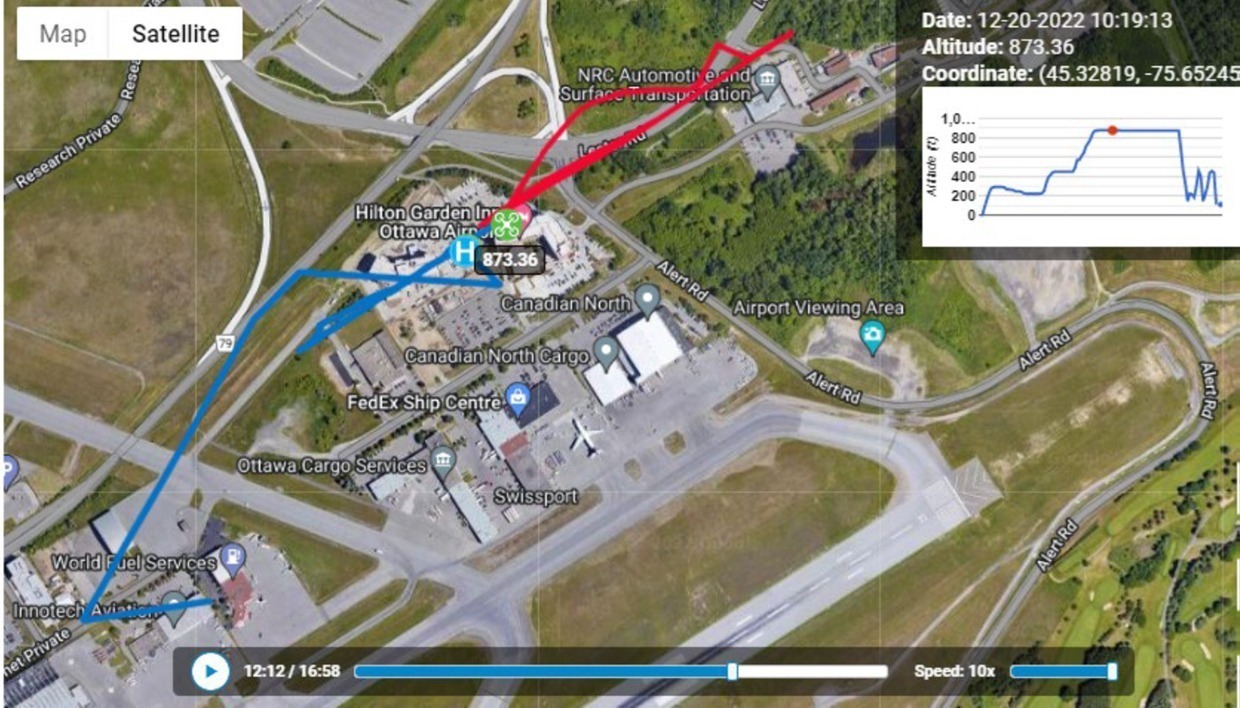

On Friday, InDro Robotics was approached by the City of Kelowna to assist in damage assessment by flying drones in the affected areas and also to carry out thermal missions. The first flights are being deployed today (Monday, August 21, 2023).

InDro is carrying out thermal missions over the city landfill, which is burning beneath the surface. A FLIR sensor will identify hot spots for those involved with fire management.

“With a rapidly changing situation, decision-makers need the best available data,” explains InDro CEO Philip Reece. “The thermal data will be useful – as these subterranean fires, which can smoulder for days and even weeks, are not visible to the naked eye.”

In addition, InDro will be flying missions to assess damage and pull together high-resolution photogrammetry. Plans are to use the Spexigon platform for those missions.

SPEXIGON

The Spexigon platform simplifies the acquisition and processing of high-resolution earth imagery using most popular drones.

The software standardises the capture to produce imagery at scale. The process begins with Spexigon capturing and indexing raw drone imagery. That imagery can then be used by the SpexiGeo software (or other third-party platforms). The imagery below was captured by Spexigon, but processed and viewed on the SpexiGeo app (you can scroll through the imagery and zoom in, revealing the high resolution).

AUTOMATED

Spexigon automates the flights; the pilot’s job is simply to monitor the airspace like a visual observer (though manual control can be taken over at any time). This automation results in greater accuracy when capturing data over targets of interest and produces a database that can easily and securely be accessed by decision-makers.

The Spexi app provides access to multiple features, including:

- Planning tools for efficient and accurate data acquisition

- Autonomous flight using the latest DJI drones

- Secure, cloud-based footage processing and sharing

- Survey work using Ground Control Points

“Obtaining high-resolution photogrammetry requires precise flying – including maintaining a consistent height above ground level,” says Reece. “The automated flights will ensure consistent photos – which will provide decision-makers with a clear picture of what’s been damaged, and to what extent.”

WILDFIRE “TOURISTS”

The spectacle of this raging fire has, unfortunately, drawn some unwanted attention. Officials say unauthorized drones flights have been taking place with people posting video to social media. The presence of drones not directly related to emergency operations is both illegal and dangerous. Water bombers and helicopters are in regular use and drones can pose a threat to those operations.

“Drones are a significant hazard to our air crews fighting fires,” said Bruce Ralson, BC’s Minister of Forests, on Saturday. “Now is not the time to take the footage or photos of active wildfires. Not only is it irresponsible, but it is illegal to fly them in fire areas.”

InDro is working closely with Kelowna emergency operations to ensure any drone flights do not pose a conflict with crewed aviation.

“This will be an ongoing operation and we’ll obviously be taking great care to ensure any InDro-operated flights are well clear of other aerial firefighting operations,” says Reece (pictured below).

INDRO’S TAKE

The wildfires near Kelowna – and Yellowknife – are obviously of serious concern. InDro hopes to make a meaningful contribution to those involved in the emergency response.

“Drone-gathered data – whether thermal or visual – helps those in charge make the best possible decisions in a rapidly changing situation,” says InDro’s Reece. “We will fly missions as long as required, and offer any other assistance we can. We hope the situation for the tens of thousands of people impacted by this disaster returns to normal as soon as possible.”

We’ll provide further updates as missions progress.

Update: Following the completion of our missions, the City of Kelowna provided the following statement.

“The Regional District of the Central Okanagan Emergency Operations Center contracted InDro Robotics to capture drone footage of the Clifton-McKinley fire area. Flights were coordinated and authorized through the Emergency Operations Center.

“The thermal imagery captured by drones improved firefighting by providing precise data on underlying fire threats. Marking specific hotspots on maps where the ground temperature exceeded safe levels allowed responders to pinpoint exactly where fires were burning underground, ensuring a more effective and targeted response. In addition, the footage allowed Emergency Operations Center staff to share imagery with directly impacted property owners, allowing them to understand the magnitude of the damage before it was safe to allow re-entry.”

Credit for feature image: Murray Foubister via Wikimedia Commons