Taking flight: Onboard a BETA Technologies electric-powered aircraft

By Scott Simmie

It’s one thing to hear about new and transformational aircraft that will blaze the path toward an Advanced Air Mobility future. It’s quite something else to see them up close – and even get the chance to fly in one.

But that’s precisely what happened during a recent trade mission organised by Canadian Advanced Air Mobility (CAAM), which included visits to Unither Bioélectronique in Bromont, Quebec – and BETA Technologies in Burlington, Vermont.

Both companies are pushing the envelope in this sector. Unither is working on a hydrogen-powered helicopter for sustainably and rapidly moving organs for transplant. And BETA Technologies is already manufacturing (and taking orders for) fully functioning electric aircraft that are in the process of FAA certification.

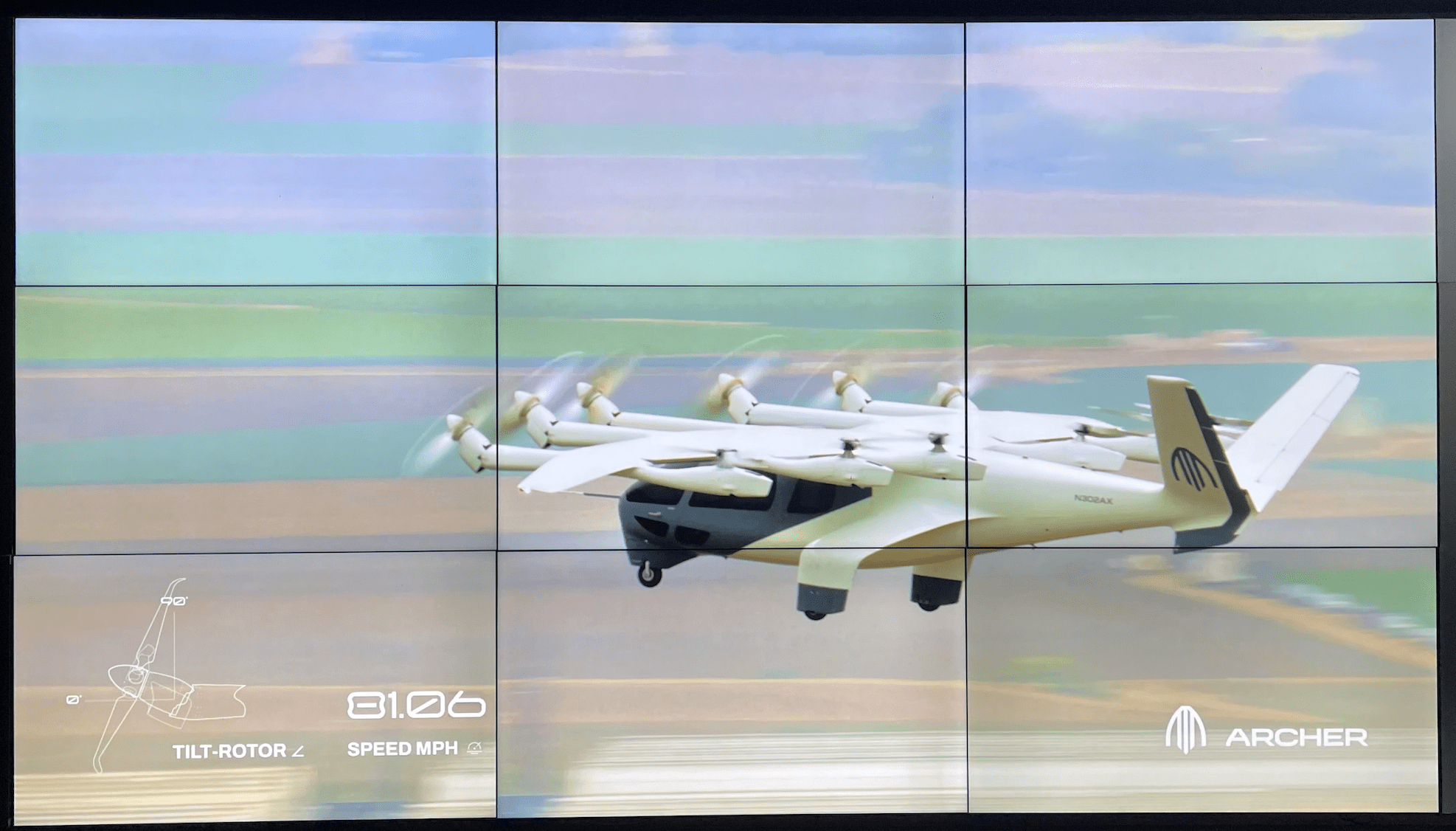

“BETA is building an aerospace company to make aviation more sustainable,” Chief Information Officer Blaine Newton told the CAAM delegation. And it’s not just the aircraft (BETA has both an eCTOL – an electric Conventional Take Off and Landing fixed-wind aircraft – and an eVTOL that takes off and lands vertically but transitions into forward, efficient, fixed-wing flight).

“We’re here to change the future of aviation,” he said. And after seeing BETA’s factory (including its incredible battery technology and charging system) – and experiencing a flight in its ALIA CX300 eCTOL – that doesn’t feel like hyperbole.

Below: The CX300 CTOL in flight, followed by the factory floor at BETA Technologies in Burlington, Vermont

THE AIRCRAFT

What would become BETA Technologies was, literally, the brainchild of its Founder and CEO, Kyle Clark. An engineer and Harvard grad, he wrote his graduate thesis on a high-wing pusher aircraft, and even built a flying scale model. Then the real work began.

“I pitched it to everyone who would listen from 2004 to 2017. I pitched it for 13 years.”

But then United Therapeutics Founder and CEO Martine Rothblatt got onboard. She has an interest in efficient and sustainable aircraft for transporting human transplant organs. The company gave BETA Technologies a $48 million US contract.

That was just the beginning. Now, with multiple eCTOL aircraft manufactured and its first production eVTOL just coming off the line (a full-scale prototype had already been built and flown), the company has an impressive trajectory and no shortage of capital.

“With an established customer base for both eCTOL and eVTOL aircraft, and more than 600 aircraft in the backlog, BETA is funded by military contracts, firm deposits, charging sales, federal financing from the Export-Import Bank of the United States (EXIM) and equity investment,” states its website. Those partners include GE Aerospace, which is investing $300 million to co-develop a hybrid-electric turbogenerator to extend range for broader use-cases.

Incorporated in 2017, BETA Technologies now has some 850 employees and is growing rapidly. With an impressive manufacturing facility, much of the aircraft is vertically integrated. It designed and builds its own motor. The company holds 440+ patents and has more than 50 charging sites in the US (including one in Canada). The CX300 eCTOL can be charged in less than an hour and has shown a maximum demonstrated range of 336 nautical miles.

“We have built and are flying five aircraft, joining the family of our existing fleet of three prototype aircraft,” says BETA’s Kristen Blodgett. These include four CX300 eCTOLs and an A250 eVTOL – with the assembly of several others underway.

And the cost of these sustainable flights? BETA says the eCTOL version is 67 per cent less expensive to operate per hour than a comparable conventional aircraft. What’s more, that aircraft has an incredible glide ratio of 17:1. And with its electric engine, it’s quiet.

“It’s about the same noise as going down the highway,” said Clark.

THE EXPERIENCE

During the tour, BETA Technologies offered three seats for a spin in its ALIA eCTOL CX300, which comes in both a five-passenger version (pilot and passenger in cockpit, four in the rear) and a cargo version. Other than the removal of four seats in the rear for cargo, the two aircraft are technically identical.

The lucky passengers were Red Deer Regional Airport CEO Nancy Paish, Langley Regional Airport Manager Patrick Sihota, and InDro’s Scott Simmie. We eagerly signed waivers we didn’t take the time to read – knowing an ALIA CX300 eCTOL had already flown across the US on a cross-country tour – then buckled up. The seats were comfortable and there was plenty of legroom. Large windows on each side of the passenger section offered an incredible view.

We taxied toward the runway with minimal noise. Unlike a combustion engine, the electric power plant noise was barely perceptible. With BETA pilot Christopher Caputo at the controls and Paish riding shotgun, Caputo let the electrons loose (394 kW on takeoff). Acceleration was immediate and smooth; the FAA-Certified five-blade propeller (built specifically for electric aircraft) is fixed pitch, so there wasn’t that additional burst of noise as pitch position changed. Small vents were open in the cockpit and rear windows. The only sound was that propellor slicing the air, the increasing air flowing through the vents, and a slight runway rumble.

Soon we were wheels-up, with Caputo controlling the aircraft through a fly-by-wire system (which could, in future, be used for autonomous flights). We flew between 4,000 and 7,000′ AGL. Caputo told us over the headphones he’d give us a demonstration of its aerodynamics. He pulled a 70° bank in one direction, then the other. The response was instantaneous and incredibly smooth. It was, in a word, precise.

“Flying in the BETA eCTOL was an incredible experience – the rush of speed, the simplicity of the aircraft, and the quietness of the cockpit where all you hear is the wind,” says Nancy Paish. “I was struck by how responsive the aircraft was and how steadily it held its position, so different from conventional flying. Experiencing this technology first-hand truly inspired me.”

After quick spin over a bit of Burlington and Lake Vermont, it was back for a smooth landing and taxi. When it was all over, Caputo simply hit a couple of switches and everything was shut down and the CX300 was ready for charging. It felt, for all passengers aboard, as if we had just been given a glimpse of the future.

“Advanced Air Mobility is not a distant concept – it is real, and it has the potential to make a meaningful difference in the aviation industry,” added Paish, who is in the midst of an ambitious expansion at the Red Deer Regional Airport with sustainable, regional aviation clearly on her radar.

“My key takeaway from this trip is clear: the future of aviation is changing, and Red Deer Regional Airport is ready to play an important role in that journey.”

Langley Airport Manager Patrick Sihota was similarly impressed.

“Witnessing BETA’s technology firsthand isn’t just inspiring; it proves the future of sustainable aviation is within reach. For Langley Regional Airport (YNJ), this is a game-changer. Aircraft like the eCTOL are perfect for connecting our communities across the Lower Mainland and the island with minimal noise and environmental impact.”

Below: InDro’s Scott Simmie about the BETA Technologies CX300 eVTOL during flight. There’s a reason he’s smiling. Image two: A view of the fly-by-wire cockpit from behind

INDRO’S TAKE

We’ve long been advocates of the coming world of Advanced Air Mobility and applaud both the sustainability – and the use-cases. There’s a real need to move critical cargo and people to regions underserved by the traditional aviation model. And, to say we were impressed with the BETA Technologies design, approach and culture would be an understatement. It’s clear why Vancouver’s Helijet chose BETA when it decided to expand into the world of electric aircraft.

“BETA Technologies is truly at the forefront of the coming wave of eCTOL and eVTOL aircraft,” says InDro Robotics Founder and CEO Philip Reece. “We were incredibly impressed not only by the thoughtful design, but the incredible amount of vertical integration we saw at BETA. We look forward to seeing the CX300 flying from Vancouver in the not-so-distant future – and on missions elsewhere in Canada as well.”

There’s much more we saw on this trip – including its impressive charging system/network, which not only charges its aircraft but can also charge EVs. The company is brimming with innovations, and we look forward to telling you more down the road.