New drone instruction portal lets new pilots go ‘FLYY’

By Scott Simmie

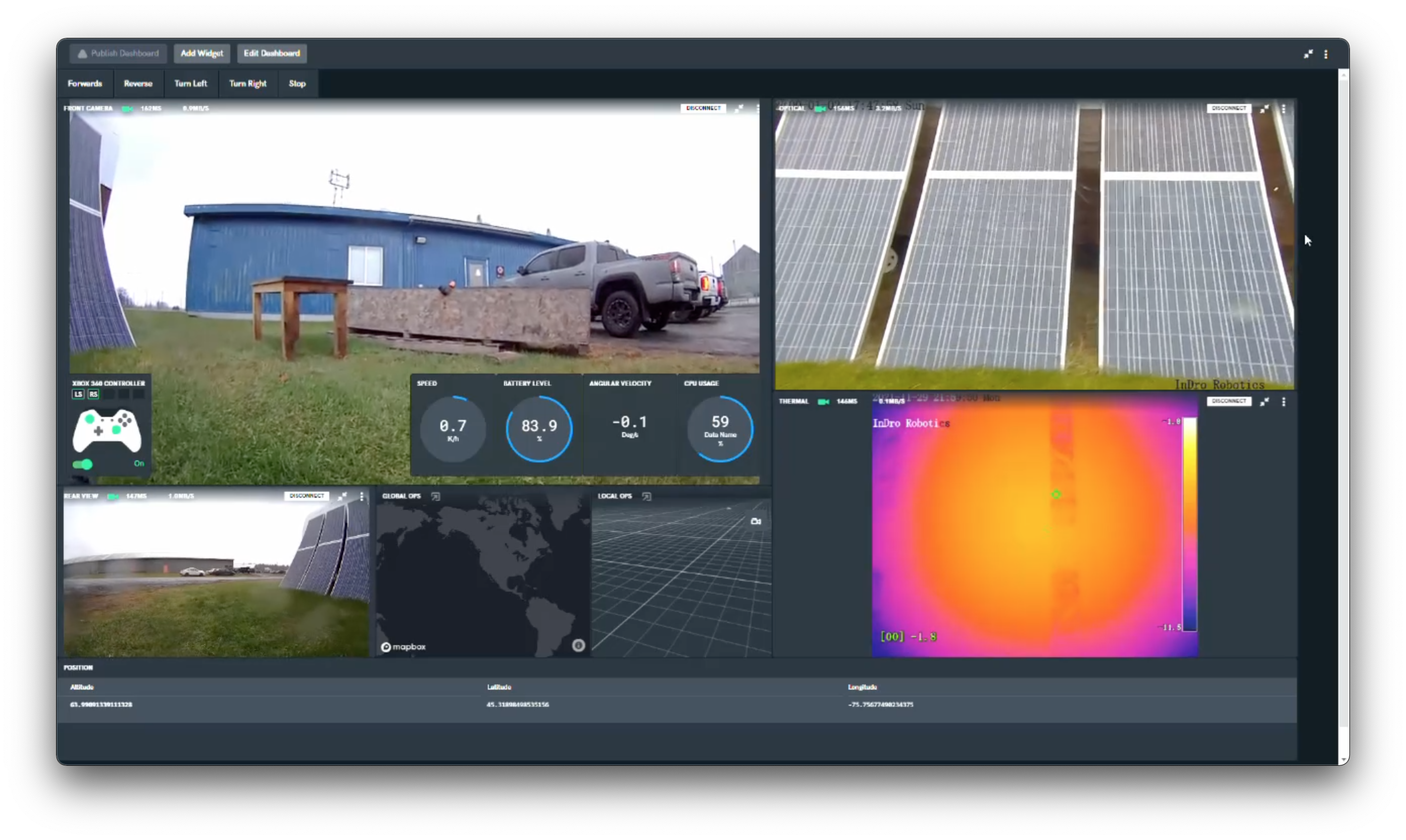

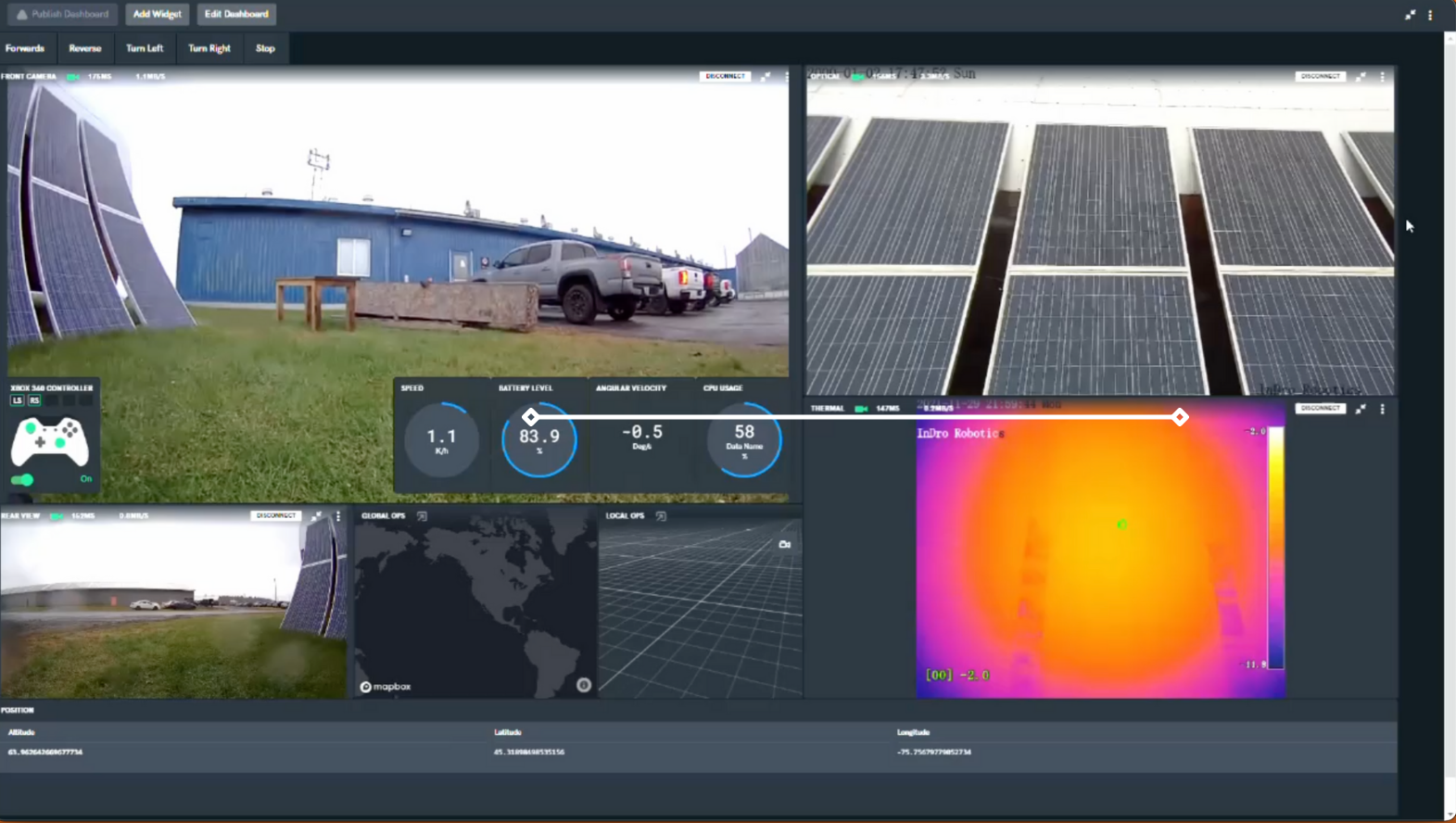

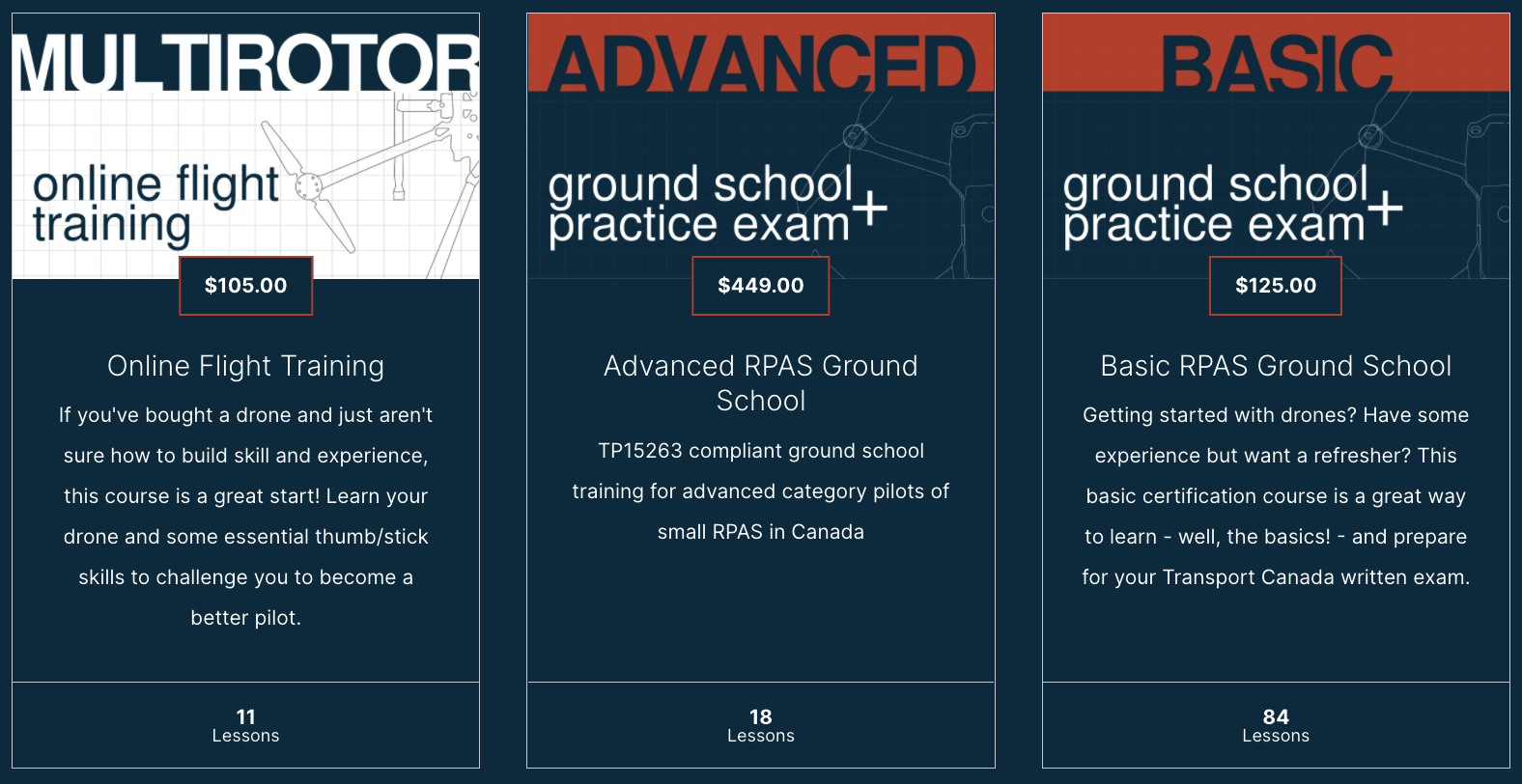

Thinking about earning your Basic or Advanced RPAS Certificate but don’t know where to start? Want some tools to help prep for your Transport Canada required Flight Review? Looking for some answers in a friendly, supportive community of drone pilots?

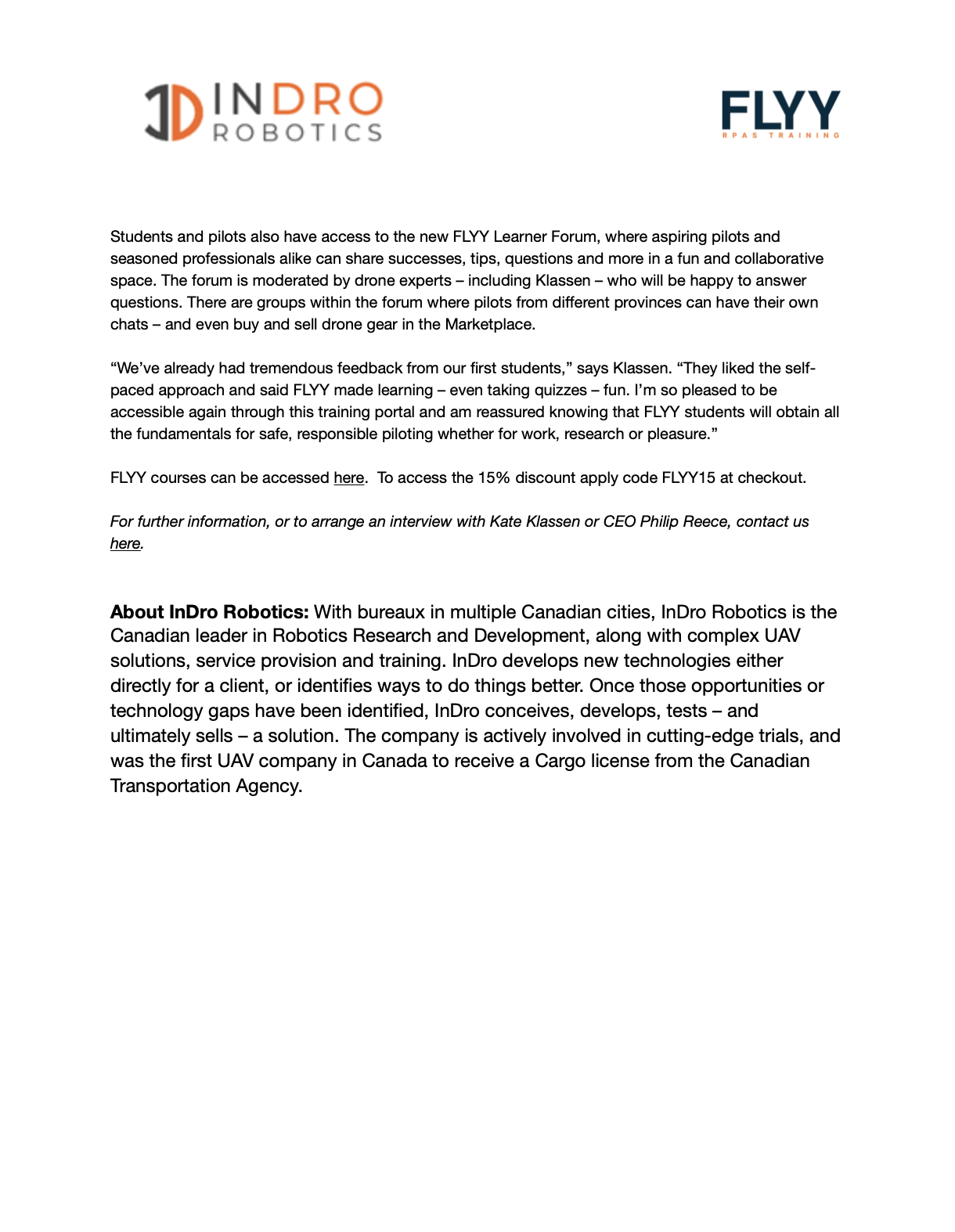

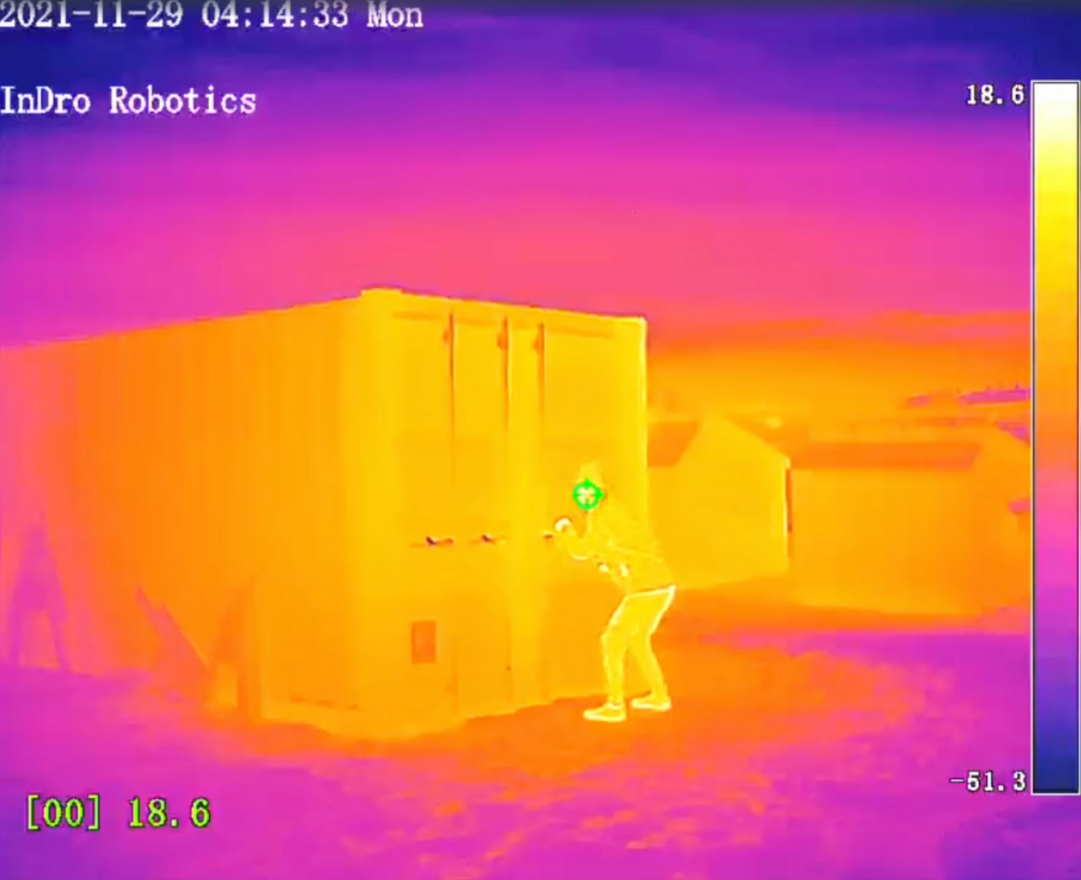

Look no further. InDro Robotics is very pleased to announce FLYY, an online drone learning portal with an incredible amount of offerings and features. What’s more, the person behind this major initiative is none other than InDro’s Kate Klassen, a highly respected professional and instructor in both the traditional aviation world as well as the drone sector.

If seeing that image of Kate in a studio rings a bell, that’s understandable: Kate developed and fronted one of the most successful online drone courses in Canada. Now, she’s taken all of that experience and expertise and put it into a comprehensive learning platform with multiple course offerings. There’s something for everyone, ranging from the absolute beginner to seasoned pros looking to up their game. There’s even a brand new and supportive Forum, where Kate and others can weigh in with helpful tips or answer questions. No trolls here; just a collaborative and growing community eager to learn and share.

We’re excited. And so is Kate.

“I’ve constructed the FLYY courses and guides to ensure success for those seeking to become Basic or Advanced RPAS pilots,” she says. “It was so fun to get back into content creation mode and then into the studio to record this training – no promises my jokes have gotten any better though!”

Special FLYY launch discount

We could go on and on. But we also issued a news release about this – so no point reinventing the rotor! We’ll paste that release in a second so you can see all the details, but wanted to point out that FLYY is offering 15% off until March 1. So if you’re in Canada and want to be ready for spring piloting, hop on over to the FLYY website and take a look at some of the course offerings.

Believe us, there’s something for everyone, including helpful FLYY Guides and even Flight Reviews. Once you’ve made your selection, apply the code FLYY15 at checkout.

The news release

Okay, for those of you looking for even more information, you can see our news release below, or download it here.

Happy piloting…and congratulations, Kate Klassen. Having been through the site, we can tell you she has done an absolutely amazing job with these comprehensive, Transport Canada compliant course offerings.