By Scott Simmie

Have an idea for a prototype? InDro Forge has got you covered.

The company can take a napkin sketch, turn it into a full-fledged design – and then produce a single prototype or limited manufacturing run.

But the Ottawa-based facility, equipped with multiple machines for additive and subtractive manufacturing and an A-level team of engineers and support staff, is now capable of much, much more.

If you happened to miss this story, here’s the headline: Back in September, InDro Robotics took over operations of what was known as the Bayview Yards Prototyping Lab. Previously run by Invest Ottawa, InDro could see the synergy of running this in conjunction with its R&D headquarters (based at Ottawa’s Area X.O).

But the acquisition has involved much more than a name change. Under the guidance of Stacey Connors (Head of Strategic Innovations) and Joel Koscielski (Senior Manager, Design and Fabrication), a longer-term plan for growth quickly began to form. Soon, there were new hires in engineering and sales. There was a comprehensive review of the existing market to identify gaps.

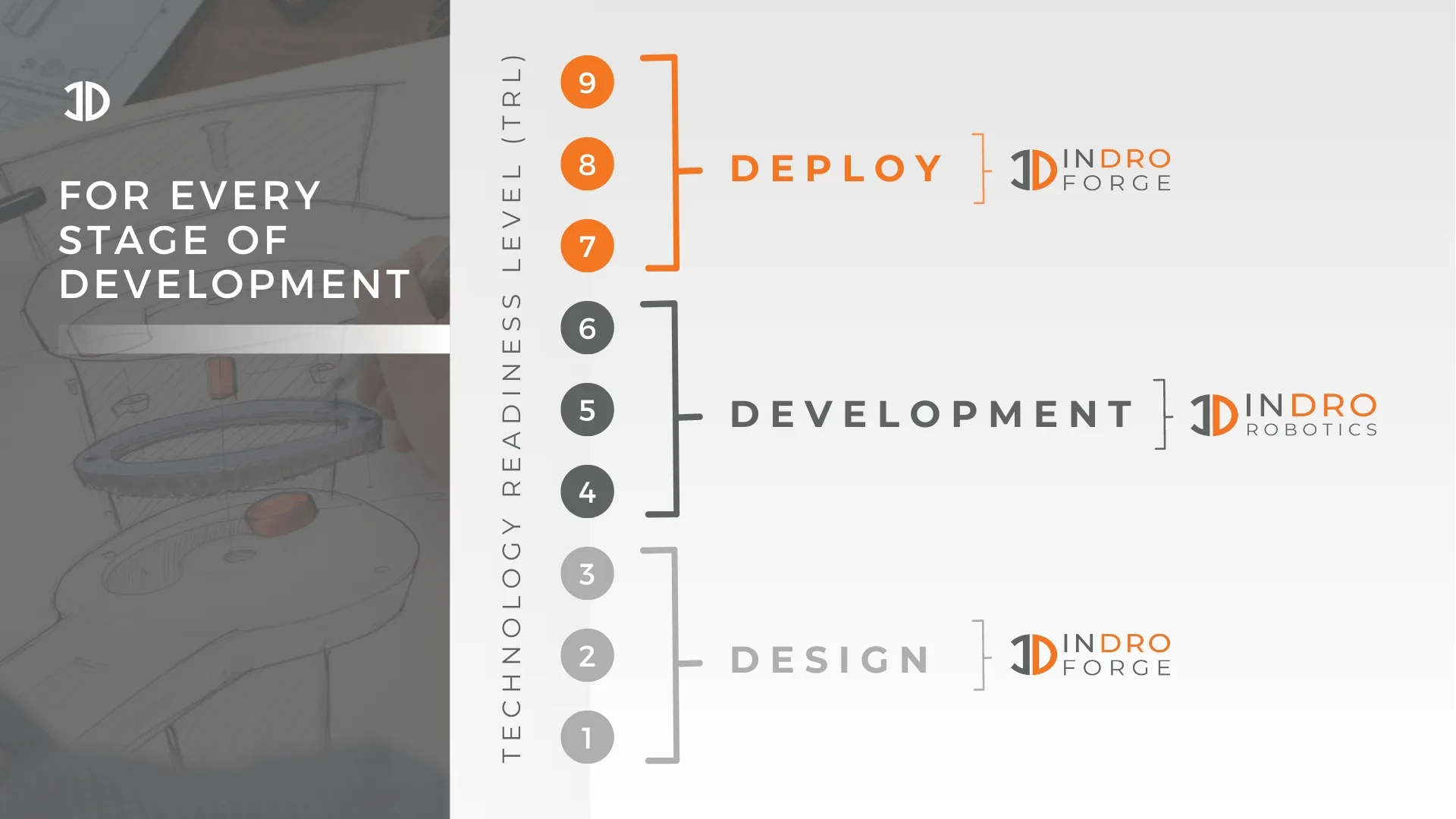

And, ultimately, a new roadmap for the future. Though prototypes will still be an important part of the core business operation, InDro Forge now has the expertise and capacity to be of service to companies with products anywhere along the Technology Level Readiness (TLR) scale.

“I was initially excited about the synergies with robotics,” says Luke Corbeth, Head of R&D Sales with InDro Robotics.

“But after seeing the all-star cast, I’m also excited for its potential as a standalone alongside InDro Robotics. There are so many other industries we can touch. I feel so confident, talking to anyone and knowing that wherever they are in their journey we’re going to be able to help. I know we can take it on – and that’s super exciting.”

It is. Now, let’s find out why – and how.

Below: The water jet table at InDro Forge. Using a fine slurry under immensely high pressure, it can slice through steel up to 2″ thick

NEW STAFF

It was clear at the outset that InDro Forge would be able to tap into the expertise of InDro engineers who work at the Area X.O site. But it was equally clear that InDro Forge would also benefit from additional full-time engineers at its own location.

We were fortunate in finding Matthieu Tanguay, a Mechatronics Engineer with a deep background in robotics, along with experience in forestry and oceanography. Tanguay also worked for four years with another Canadian robotics leader, Clearpath. He helped design, validate and deliver multiple different robots to clients during that period (including a robot custom-built for Antarctica).

“I’ve always described myself as a ‘Jack of all trades'” he says. “I’ve always been a curious person with a wide variety of interests. At InDro Forge I think I will be able to tap in these skillsets acquired through the years to help InDro Forge push through to another level.”

Stephan Tzolov was eager to make the jump from Area X.O to join the growing team at InDro Forge. Tzolov has a degree in Industrial Design – and design is integral to the InDro Forge process. Tzolov also loves learning new skills, and saw a perfect fit with InDro Forge.

“I made the jump to InDro Forge when I wrapped up a large, long-term project,” says Tzolov. “Timing worked out perfectly in that we had just announced the new expansion into Forge and the cool new opportunities for a dedicated mechanical engineering/design team. With the new skills and technical know-how I’d acquired via that large project, I decided to push my abilities even further by helping build up the team.”

Tzolov already had experience with a range of production tools. For the past few months, he has immersed himself in learning new ones.

“There were already quite a few machines and tools I’d familiarized myself with via my university education. However, in recent months it’s been quite the deep dive on these machines and processes – including operating the waterjet cutter and CNC.”

Below: Stephan at the controls of the waterjet cutter

THE PATH TO PRODUCTION

Prior to becoming InDro Forge, the lab specialised in designing and producing prototypes. And while that will still be part of its business model, the company is positioning itself to take on clients with products that are anywhere along the TRL scale. Perhaps you’ve already got a prototype – but it doesn’t have quite the look and feel desired. Maybe you have a functioning product that has some bugs. Or perhaps you’re looking for a polished, finished product that can be shown to your own clients or displayed at a conference. InDro Forge does it all.

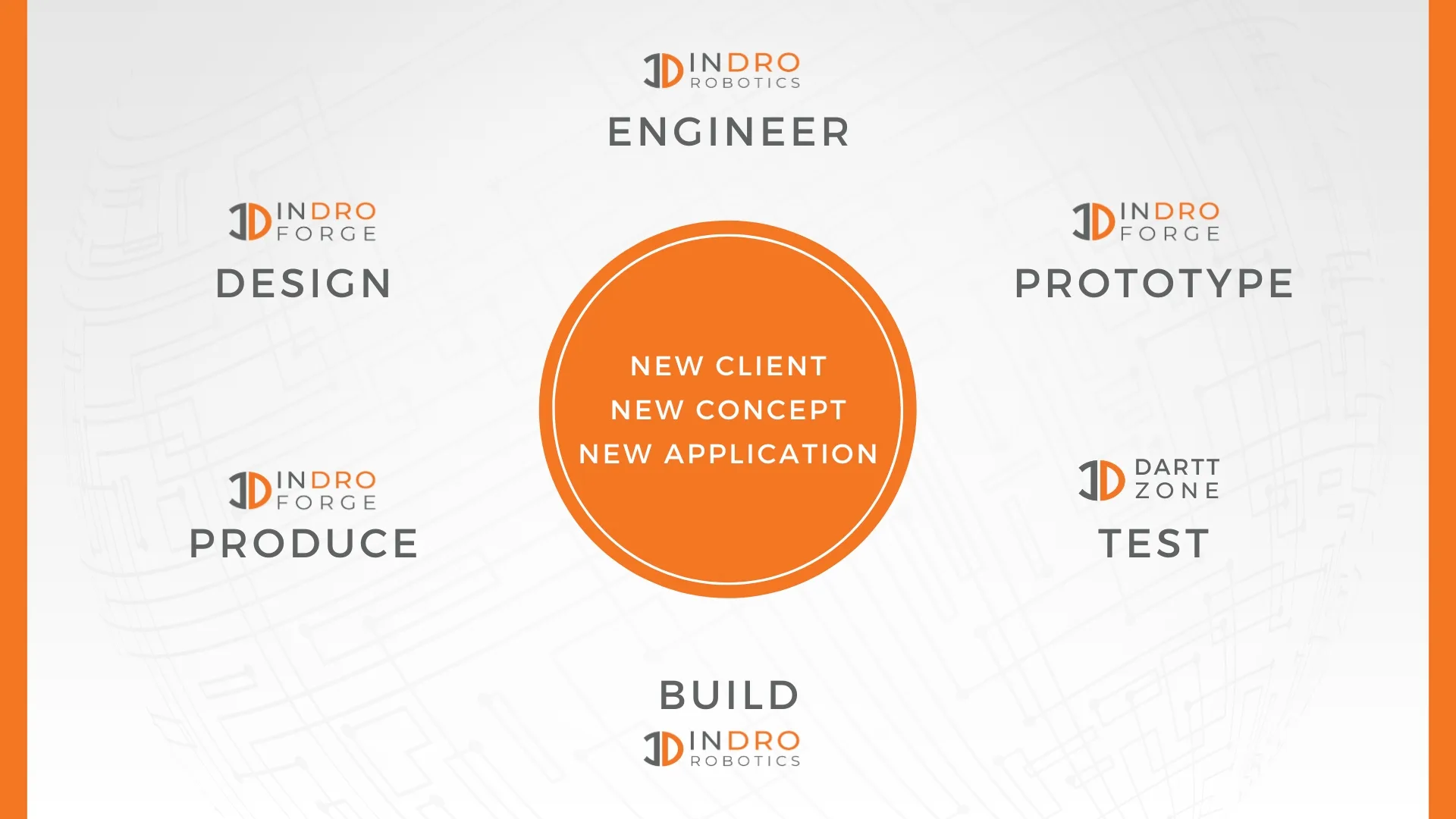

“Our initial conversations with industry partners have helped us identify, these are the things that matter,” explains Connors. “We can help customers wherever they are on the TRL.” Offerings include:

- Design

- Production

- Builds

- Prototypes

- Testing/validation

- Engineering

Whether it’s a new client, a new concept – or a completely new application – InDro Forge can shape the path to a finished product. And while there are other companies out there (and some doing very good work), we believe that the synergy of InDro Forge’s leadership and staff – combined with the R&D expertise of InDro Robotics and our state-of-the-art production tools – sets us apart.

“We are leading with technical expertise – that’s our strongest differentiator,” says Stacey Connors. “We work closely with clients – with recommendations, collaboration and consultation – every step of the way. And we really have a wide array of equipment.”

Below: How the relationship between InDro Forge and InDro Robotics works for clients

NEW SUPPORT

Companies need clients. And clients need knowledgeable staff who truly understand their needs – people who understand both the technical requirements and the customer journey. InDro Forge is fortunate to have newly hired Account Executive Callum Cameron. With a Bachelor of Commerce degree from the University of Ottawa – and a passion for understanding the technical side of things – Callum isn’t simply after sales. He is dedicated to helping customers find the precise solution to their needs, along with keeping them in the loop throughout the process.

“InDro Forge provides clients with end-to-end prototyping services that can turn any idea into a ready-for-market product,” he says. “Our services help businesses of all sizes accelerate their time to market and pathway to profitable growth.”

As part of getting settled into the role, Callum researched other companies offering similar services, drilling right down to the capabilities and machines at those facilities. And he’s reached some conclusions.

“InDro Forge offers a range of specialized services that competitors simply can’t replicate. We have the technical expertise and a state-of-the-art facility that allows clients to choose different levels of involvement along their prototyping journey. Furthermore, our team has years of experience in every phase of rapid prototyping, which allows us to guide our clients in the right direction every step of the way.”

INVESTMENT

In the transition to InDro Forge, great emphasis was put on identifying areas – and hires – that would allow for greater capacity going forward. Senior Manager of Design and Fabrication Joel Koscielski, who was previously with the Bayview Yards Prototyping Lab, sees that as a significant step forward.

“InDro made an immediate investment in building the Forge team by adding new capacity. We now have an Applications Engineer to help clients develop a solution tailored to their needs, plus a Mechatronics Engineer to bring a greater technical expertise in the integration of mechanical, electrical and code into a single solution.”

The other significant difference is the new ability to tap into the broad expertise of the InDro Robotics engineering team, based at Area X.O.

“The InDro Robotics engineers being included in design reviews or in a design consulting capacity during projects ensures higher quality output from Forge – and the opportunity for more creativity in solutions. The InDro team also has a large number of industry contacts including trusted suppliers and partners which pre-date the InDro Forge. These contacts have served to bolster the list of partner companies which Forge draws from to deliver great prototypes when the needs exceed our in-house capacity or current equipment capabilities.”

In addition, the InDro Forge team all share a trait that’s reflected in their work ethic, and ultimately the finished product: Passion.

“The best part of starting a project from scratch is being able to breathe life into something that was originally just an idea, maybe just a sketch on a piece of paper,” says Stephan Tzolov.

“Taking that spark of innovation from an idea to reality never gets old. So, I’d say those beginning steps of concept development and iterative design are the most rewarding.”

Below: InDro Forge’s new Mechatronics Engineer, Matthieu Tanguay

INDRO’S TAKE

We obviously felt there was a synergy in developing InDro Forge. And while the Bayview Yards Prototyping Lab was known for its excellent work, we wanted to both expand in-house capabilities and leverage the expertise of our Area X.O engineering team. The result, we believe, is a solution we intend on refining until it is unrivalled in the country.

“Expanding the core team at InDro Forge, and creating a roadmap under the guidace of Stacey Connors, was the first step,” says InDro Robotics CEO Philip Reece.

“We now have outstanding in-house capabilities, with more hires to come. That, in combination with the ability to tap additional expertise from our Area X.O team, positions InDro Forge for a truly exciting path forward – both for InDro Robotics and for InDro Forge clients.”

Interested in learning more? Feel free to contact Account Executive Callum Cameron here.