By Scott Simmie, InDro Robotics

If you’re in the drone industry, you’ve likely heard the phrase: “Drone-in-a-box.” If refers to an autonomous system where a drone nests inside an enclosure for charging and safe harbour – and is regularly dispatched for automated missions. Usually, those missions are pre-programmed and involve inspection, surveillance, or change detection. Manual missions can be carried out when necessary, but the real point is automation.

The idea is that missions are carried out repeatedly, with a human simply monitoring from a remote location. Remotely could mean inside a building on an industrial site where the drone is based. But, because these emerging systems operate using LTE to control the drone and communicate with the software, they can be operated from hundreds or even thousands of kilometres away (providing you have permission to operate Beyond Visual Line of Sight and an available LTE network). With missions carried out automatically and on a regular schedule, this makes for vastly more efficient inspections, surveillance, tracking of construction progress, etc.

It beats requiring a pilot on site, and the drone never suffers from fatigue. The advantages for Enterprise clients are immediately apparent: Inspections, surveillance or general monitoring take place like clockwork, with all relevant data stored for easy access and interpretation. But think also of the edge such systems could provide for First Responders: A drone could be automatically dispatched to the location of a 9-1-1 call or critical incident. Video or thermal imagery can be securely live-streamed to decision makers down the line, regardless of where they’re located. The potential of such systems is unlimited.

At InDro Robotics, we’re no strangers to this concept. In fact, we’ve got a few things under the hood in this regard. But we like to acknowledge and celebrate success in this field. And so today’s post will focus on Percepto – the world’s leader in drone-in-a-box solutions. The company has a proven system, currently deployed in more than 100 locations around the globe. We recently had an opportunity to see a demo of the Percepto system, hosted by Canadian distributors RMUS (Rocky Mountain Unmanned Solutions).

Percepto’s autonomous drone system

The Percepto website outlines its offering with this statement: “Changing the way visual data is collected and analyzed, Percepto AIM is the only end-to-end inspection and monitoring software solution that fully automates visual data workflows, from capture to insights.” AIM stands for Autonomous Inspection and Monitoring, and is the software integral to the overall package.

This Percepto video provides a good overview:

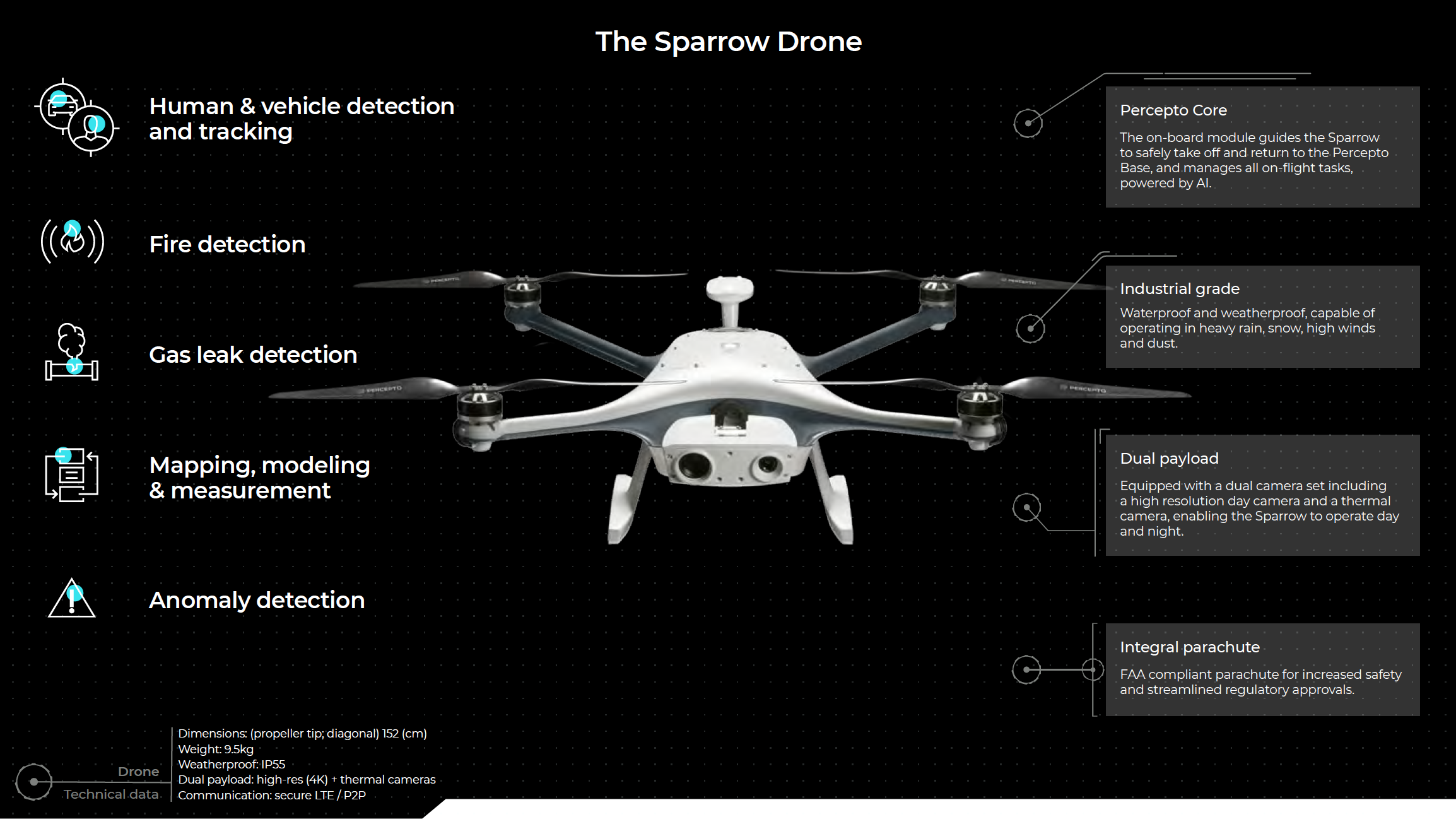

It’s one thing to see a company video, quite something else to see that system in person. We were part of a briefing with Percepto’s Ehud Ollech (Head of Business Development) and Shykeh Gordon (VP Global Sales). They demonstrated the AIM software, the Sparrow drone (which comes with a parachute), and much more.

But they started by explaining that this system is purpose-built for major industrial customers, with clients from the mining, solar, oil & gas/petrochemical and utilities sector. And, they said, don’t think of Percepto as a drone company.

“Basically we are a big data analytics company,” said Shykeh, “offering end-to-end inspection and monitoring solutions.” What kind of solutions? This corporate graphic, supplied by Percepto’s marketing department, helps explain:

Percepto’s AIM software

During the demonstration, Shykeh and and Ehud walked us through the AIM (Autonomous site Inspection and Monitoring) software. It’s a browser-based system that allows you to program missions, monitor flights in real-time, watch a live stream from the Sparrow drone’s RGB or thermal camera, and take a deep dive into meaningful data. The User Interface is simple, and Percepto says a mission can be planned in as little as three minutes. In fact, they flew a brief mission from indoors with visitors watching from a conference room and visual observers outside. Every aspect of the mission, including a live video feed, was delivered in real-time. We could monitor what the drone was seeing, which is part of the point. And Ehud had the option, if something caught his eye, of stopping for a closer look.

RGB and thermal data is continuously captured during missions, then uploaded to the AWS cloud when the drone comes home to roost. Significantly, the AIM software is capable of change detection – a major feature for many clients. Once a baseline capture of a designated area has been stored in the Cloud, if a subsequent mission detects any changes, anomalies will be flagged. These could include thermal changes, issues with solar panels, oil leaks, a broken window – the list goes on. (The thermal data is radiometric, meaning it provides the actual temperatures measured.) The AI does not always categorize the type of anomaly, but even when it doesn’t it will quickly point out the relevant images for the operator to take a closer look. Percepto can also be integrated with Smart Fences or Pan-Tilt-Zoom cameras and dispatched automatically if something seem amiss.

“The heart of our system is our software,” says Ehud.

AIM can also integrate data from ground-based robots, such as Boston Dynamics’ Spot. Even a smartphone photo or other image can be added to the mix, providing it contains geolocation data. The system can produce 3D digital twins, with all photogrammetry stitching done in the Cloud by AIM. (Some solutions for automated data capture rely on third-party software for photogrammetry.) As part of the demonstration, Ehud defined an area of a pile of earth; a volumetric calculation was instantly performed. And this was all while the group was comfortable indoors. We were probably 50 metres from the actual system, but we could have just as easily have been across the planet, assuming LTE connection at the drone end.

Seeing the Percepto drone in a box in action

After the first mission was complete, we went outside to watch the system in person. It began with the clamshell housing – which Percepto says can withstand a Category 5 hurricane, closed. Once the mission was initiated, it opened up quickly and the Sparrow took off. The system is operational in winds up to 40 kph, with a takeoff/landing limit of 27 kph. Winds during the demo were 24 kph; the Sparrow was rock steady.

The system does not have obstacle avoidance, but uses ground-based radar to avoid conflicts with crewed aircraft. Altitude parameters, obviously, are programmed when setting the mission.

“Everyone’s waiting for aerial radar to get cheaper and lighter,” said Shykeh.

More sensors to come

The company already is working on a gas detection sensor (aka OGI camera), and is looking at potential LiDAR sensors as well. Maximum flight time is 40 minutes under optimal conditions, but generally flights are limited to 30 minutes. The next generation battery will offer a 20-30 per cent increase in time and range, and charging time in the station – from zero to full – is about 40 minutes.

InDro’s view

This is a refined and mature system, well-suited for major corporations with the budget for this kind of data acquisition and interpretation. It’s particularly suited for remote sites – especially sites that do not have staff on site but require persistent monitoring for safety, security or other reasons. Percepto has some very high-profile clients on its roster, including FPL, Koch, Verizon and Enel.

We’re strong supporters of drone-in-a-box solutions – and are actively exploring systems that might be helpful to First Responders. Kudos to Percepto…and stay tuned.