By Scott Simmie

There’s no denying climate change. Whether it’s the recent and devastating floods in Pakistan, fires in Portugal – or the multiple rivers globally that have dropped to historically low levels – the planet’s equilibrium has been changing.

While carbon dioxide emissions get much of the press, methane is one of the most potent contributors to the problem of greenhouse gases.

“Methane has more than 80 times the warming power of carbon dioxide over the first 20 years after it reaches the atmosphere,” states the Environmental Defense Fund.

“Even though CO2 has a longer-lasting effect, methane sets the pace for warming in the near term.”

That’s a key reason why the detection of methane emissions has become a priority. It’s also a large part of why Aerometrix – a company specialising in methane detection using drones – was formed.

Below: One of the early Aerometrix rigs for methane detection. The sensor is at the forward end of the counter-weighted rod to keep it clear of prop wash.

Aerometrix

Before we get more into what Aerometrix does (and how it does it), we should point out there’s an InDro Robotics connection here. InDro CEO Philip Reece, along with Michael Whiticar, founded the company. Aerial operations for Aerometrix are carried out by InDro Robotics.

“We felt there was a void in the marketplace for the detection of methane and other gases,” explains Reece. “We also wanted to approach this from an engineering-first perspective, ensuring that we were using, and even developing, the best available sensors and workflow.”

Aerometrix uses two different types of sensors for methane detection. The first is the proprietary GasMap sensor, which is capable of detecting methane in parts per billion (ppb). This laser-based sensor had its origins at NASA’s Jet Propulsion Laboratory, where it was developed for Mars missions. Aerometrix has further refined that sensor and has used it to accurately map methane emissions at petrochemical plants, gas wells, landfills – and even on agricultural sites. (Animals, particularly cows, are a significant methane source.)

“GasMap uses laser spectroscopy,” explains Peter Sherk, an electronics engineer with Aerometrix. “It uses the absorption of lasers by methane to detect concentration. And it’s very precise – detecting not only its presence, but how much there is at a given point in time and space right down to parts per billion.”

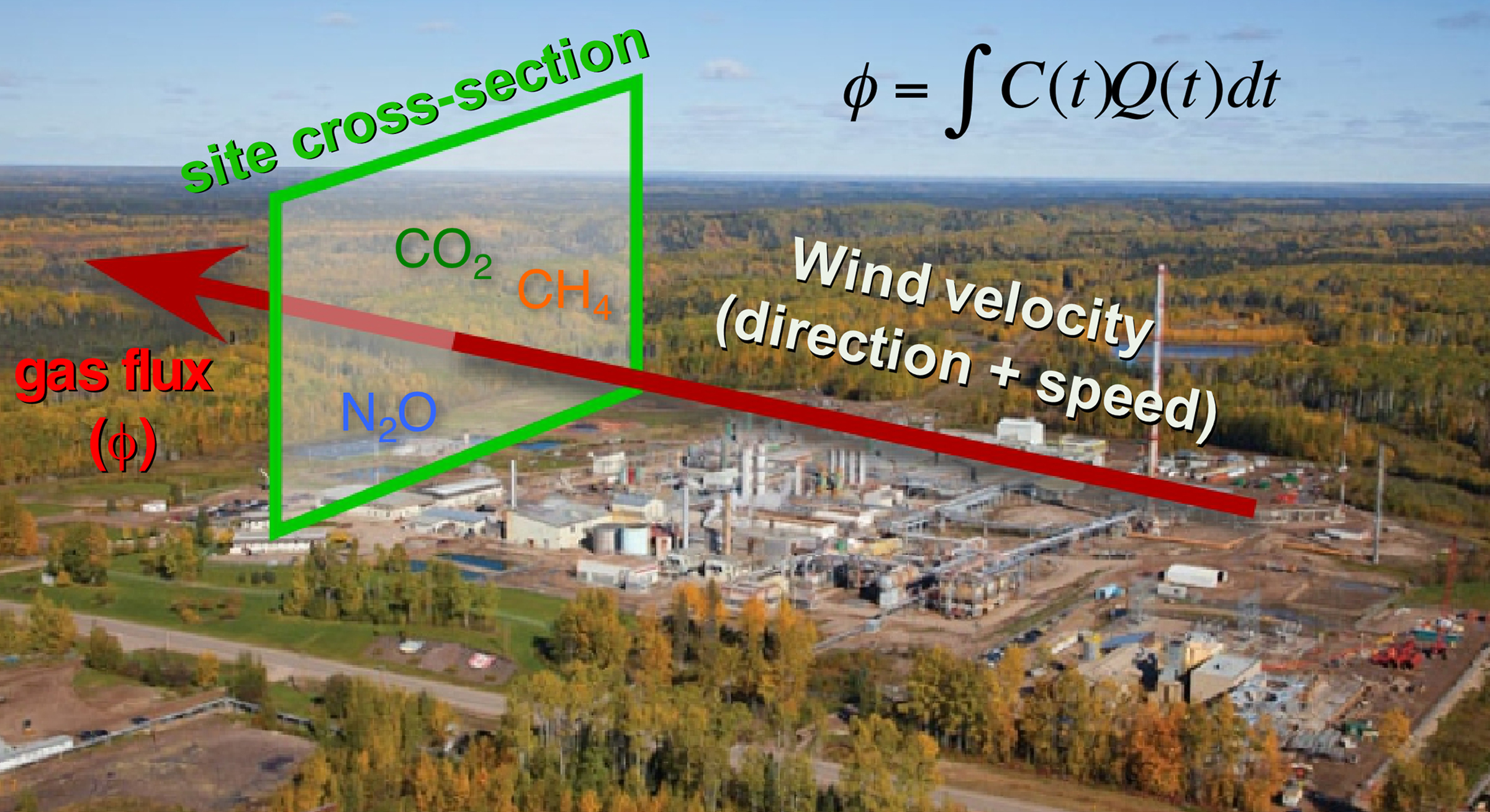

The sensor maps methane (and other gases) by flying horizontally through the plume. When multiple passes at different altitudes have been completed, a “curtain” is obtained. (Don’t worry, we won’t ask you to carry out the calculation – besides, our FluxCurtain software does that.)

Zig-zag

As mentioned, the drone flies horizontally through the plume – with each parallel flight at a slightly higher altitude. The sensor is constantly capturing georeferenced data which Aerometrix then runs through software.

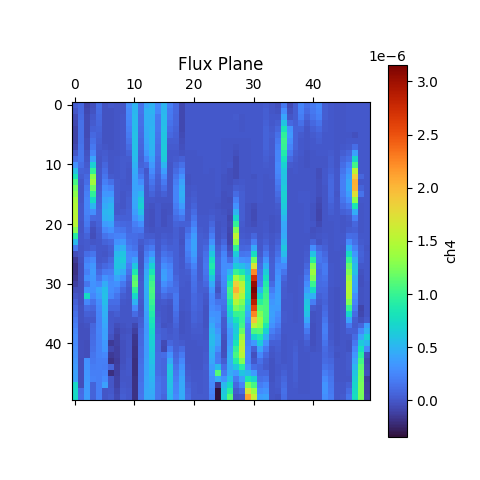

In the images below, you’ll see that zig-zag flight pattern. The blue lines at the bottom indicate methane concentrations. Not surprisingly, those concentrations begin to dissipate at higher altitudes as the methane plume mixes with the surrounding air.

The second image is what’s referred to as the actual “Flux Plane” – where the methane concentrations are represented visually by colour.

Efficiency

Though pipelines and facilities that handle methane are obvious places where detection is required, local city dumps are also interested in detecting – and even capturing – methane produced by buried garbage. But many are unaware of the efficiency and accuracy of using sensors like the GasMap mounted on a drone.

“A lot of landfills are doing methane detection already,” says Sherk, “but they’re using far less convenient methods. A lot of the time there’s someone walking back and forth with handheld sensors. With larger landfills any sort of grid pattern will take days and days – and walking over an old landfill can’t be a really healthy operation.Operating a drone is vastly more efficient. And the GasMap sensor is capable of detecting not only the presence of methane, but its concentration at various altitudes as the gas forms a plume and mixes with surrounding air.

Some landfills have been able to not only capture but exploit methane that was previously escaping. The Capital Regional District on southern Vancouver Island has been running a power generating plant on-site at the Hartland Landfill, fuelled solely by captured methane produced by decomposing garbage. It’s been doing so since 2004, creating enough energy to power 1,600 homes.

Recently, the volume of methane produced by the landfill has increased, and the power plant is nearing the end of its operational life. In 2023, the landfill will switch gears and process the biogas into natural gas – selling the product to FORTIS BC.

Kudos to the Capital Region District for having such foresight; the example also highlights how captured methane can be put to positive use.

Aerometrix has carried out surveys now at numerous landfills hoping to capture or otherwise mitigate methane emissions. Using FluxCurtain software, its reports turn what was previously an invisible problem into clear, actionable data that provide a clear picture of emissions and concentrations.

Another sensor

We mentioned a second sensor also being used by Aerometrix. It’s called the LaserScan, and it’s a very lightweight sensor that also uses laser spectroscopy to detect the presence of methane.

Unlike the GasMap, the newer sensor is able to measure vertically. In other words, the drone can be flying directly above a plume and take a measurement straight down to the ground. While it’s not quite as precise as the GasMap sensor (parts per million, rather than parts per billion), the LaserScan does have an advantage when it comes to speed.

Because it does not rely on flying through the plume, the LaserScan is ideal for detecting emissions over large areas. By simply flying a grid pattern at a single altitude, it can rapidly identify emissions. At an altitude of 98.4′, it’s capable of detecting 500 ppm of methane with a plume diameter of one meter.

“While the Falcon is less precise than the GasMap sensor, it has a definite advantage when it comes to speed,” explains Keegan Richter, a mechanical engineer with Aerometrix.

In cases where greater precision is required, Aerometrix can fly two missions: The first with the LaserScan to rapidly detect the location of emissions – particularly over large landfills – followed by GasMap for parts-per-billion accuracy.

InDro’s Take

We obviously have a special interest in Aerometrix, since InDro’s pilots and drones carry out its aerial missions.

Not surprisingly, since CEO Philip Reece is a co-founder, the mission of Aerometrix closely aligns with InDro’s guiding philosophy: Developing and utilising technology to increase efficiency and – whenever possible – contribute to positive change.

Arguably, the dramatic and apparently escalating shifts we’ve seen to global climate patterns are one of the most pressing problems on the planet. Methane is a key contributor to those changes.

The ability of Aerometrix to accurately detect methane emissions has already helped clients cap leaks and examine other methods for capturing this gas before it hits the atmosphere. Its missions have also meant that human beings are no longer exposed to hazardous environments while capturing data using handheld devices.

In our mind, those are both positive outcomes.

Interested in more information? You can contact Aerometrix directly here.