InDro’s Kate Klassen gives briefing to lawyers on drones and AAM

By Scott Simmie

Want a quick overview on drones? One with a specific emphasis on the state of Canadian regulations and where things are headed – including Advanced Aerial Mobility?

Well, the bad news is that you missed an excellent presentation by InDro’s Kate Klassen February 7th. Klassen was invited by the Canadian Bar Association, BC Branch (CBABC), to present on precisely that topic. The event was a meeting for the CBABC Air Law Section and was titled: Drones, Robotics and Advanced Air Mobility Confirmation. CBABC Members gathered in Vancouver, and broadcast the meeting live to an online audience.

The good news? We watched it. And, because Klassen works for InDro Robotics, she kindly passed along the deck used in the presentation. By simply reading this story, you’ll get the high-level low-down on the following topics:

A BIG TOPIC

That’s a lot of information to go through, but Klassen is a pro. Plus, we’re not going to dive into absolutely everything she talked about – just the highlights for a busy person like you.

Kate Klassen was one of those people who could see the potential of drones quite early. That’s not surprising, given that she was already a professional in traditional aviation. She’s a Flight Instructor and commercial pilot with ratings for multi-engine aircraft, as well as flying by instruments only (IFR) and at night.

That’s a lot of experience, and her expertise is widely recognised in the aviation and drone worlds. In fact, Klassen has has been consistently active in the sector-at-large: She’s been on the Board of Directors of the Aerial Evolution Society of Canada (formerly Unmanned Systems Canada) since 2018. She’s also served as co-chair of Transport Canada’s Drone Advisory Committee, also known as CanaDAC, as well as with COPA (Canadian Owners and Pilots Association).

“I got into drones about 10 years ago, and it was a pretty traditional route into drones,” she said. “At the time, you were either a really excited hobbyist, you came from (a sector) like defense, or you were working in traditional aviation and then made the jump over to the ‘unmanned’ – that’s what we called it at the time – side.

“I like to joke that everything that I’ve flown has been unmanned,” she quipped.

She also promised “There are some really exciting things on the horizon for the drone industry.”

And when it comes to that…she’s definitely not joking.

Below: Kate, just after completing her seminar

THE BASICS

Klassen quickly jumped into the current regulatory space, outlining the existing rules in Canada. She explained that regulations covering Remotely Piloted Aircraft Systems (RPAS, or drones) are covered in legislation under Part IX of the Canadian Aviation Regulations.

“It’s really regulating three things: The pilot, the product and the procedures,” she explained, adding “Drones are regulated based on risk…it’s the weight of the drone and where you intend to operate it.”

There are currently three classes of drones: Those weighing 249 grams and less (micro-drones), those from 250 grams to 25 kilograms (small drones), and 25.1 kg to 150kg (medium).

Under current regulations, a Transport Canada-issued RPAS Certificate (an operator’s license for drones) is not required if you’re flying a micro-drone. They can be flown over people and even in dense urban settings (pending local bylaws) – providing you use common sense.

“So really there’s only a few rules for micro-drones. There’s the Part VI regulations that apply to all aircraft that say ‘don’t fly in restricted areas like over forest fires’. And then in Part IX there’s only one regulation, and it’s the ‘don’t be an idiot rule’. Don’t be wreckless or cause a hazard to other airspace users or people below you. And those are really the only rules that apply.”

Operating anything 250 grams or heavier requires either a Basic or Advanced Certificate from Transport Canada. A Basic certificate allows you to fly in uncontrolled (Class G) airspace up to 400′ above ground level (with some restrictions that keep you a safe distance from people on the ground). An Advanced Certificate permits flights to the same altitude in controlled airspace – where aircraft are subject to NAV Canada’s Air Traffic Control system – albeit with fewer restrictions. For example, you can fly closer to people.

Under current regulations (subject to change in the not-so-distant future), special permission from Transport Canada is required if you want to fly your drone Beyond Visual Line of Sight (BVLOS, or farther than you can see it with the naked eye), or if you are flying a drone weighing more than 25 kilograms. If you’re flying anything heavier than a micro-drone in controlled airspace, you also need to notify and receive the green light from NAV Canada, which is a snap with the NAVDrone app.

There’s more, of course. If you’re interested in learning the rules in greater depth, we recommend you take a read of RPAS 101, created by the Aerial Evolution Association of Canada in conjunction with Transport Canada. Klassen was one of the key contributors to the document, which you can find (in both official languages) here.

Below: Kate Klassen, in her element.

TRENDS

Remember those micro-drones? They’ve become not only exceedingly popular, but also increasingly powerful. With extended flight times, high resolution cameras – and the ability to fly pretty much anywhere, including dense urban environments without additional permissions – Klassen says they’ve rapidly become an unexpectedly important part of the drone sector.

She specifically pointed to how a company called Spexi Geospatial is leveraging this technology – along with the ability for pilots to fly without a Transport Canada RPAS Certificate – with a specialized software platform. The Spexi software allows pilots to fly pre-programmed flights that capture imagery at scale. The software carries out the flight, including capturing photos at precise intervals so they can be stitched together into a hexagonal ‘Spexigon’. This ability to capture imagery at scale has already been used to create orthomosaics of entire cities in just days. Depending on the mission, pilots who complete certain missions can be paid cash or points (which act as credits for their own Spexi missions) – with potential plans for crypto tokens down the road. In fact, Spexi just announced plans for what it believes is the largest ever drone imagery capture attempted (details here).

“They’re kind of maximising this regulatory structure, the ability to operate micro-drones in environments that would be a lot more challenging if the aircraft were heavier,” explained Klassen. “Someone can take an $800 drone and turn it into a business.”

AI AND MACHINE VISION

With the growth of powerful software, including AI and Machine Vision libraries (where objects can be detected, identified and classified), Klassen said drones have been finding new use-cases. For example, a drone can be sent on a mission where it’s looking for change detection in infrastructure. Do these power line insulators look the same as they did on the last flight? Is there corrosion or cracks in critical infrastructure like bridges? Are any of those bolts sheared or damaged? Is that component too hot?

Drones with the right software and sensors can now detect such anomalies automatically. They can even forecast routes that a missing person is most likely to have taken during Search and Rescue missions based on last known location, heat signatures, path detection, etc. There’s also the business of building inspection, where a drone can automatically detect everything from poor insulation to missing shingles or other damage. There are even specialized drones equipped with sensors for Non-Destructive Testing, where a probe is physically applied to a surface during flight to detect for rust, paint thickness, weld integrity – and more.

So as AI has increasingly been applied to drones, their capabilities and utility have greatly expanded. They’ve also made the job simpler.

“So erecting scaffolding and shutting down sidewalks and preventing work from happening while the inspection’s taking place – you can cut down on a bunch of expenses that way as well,” she says.

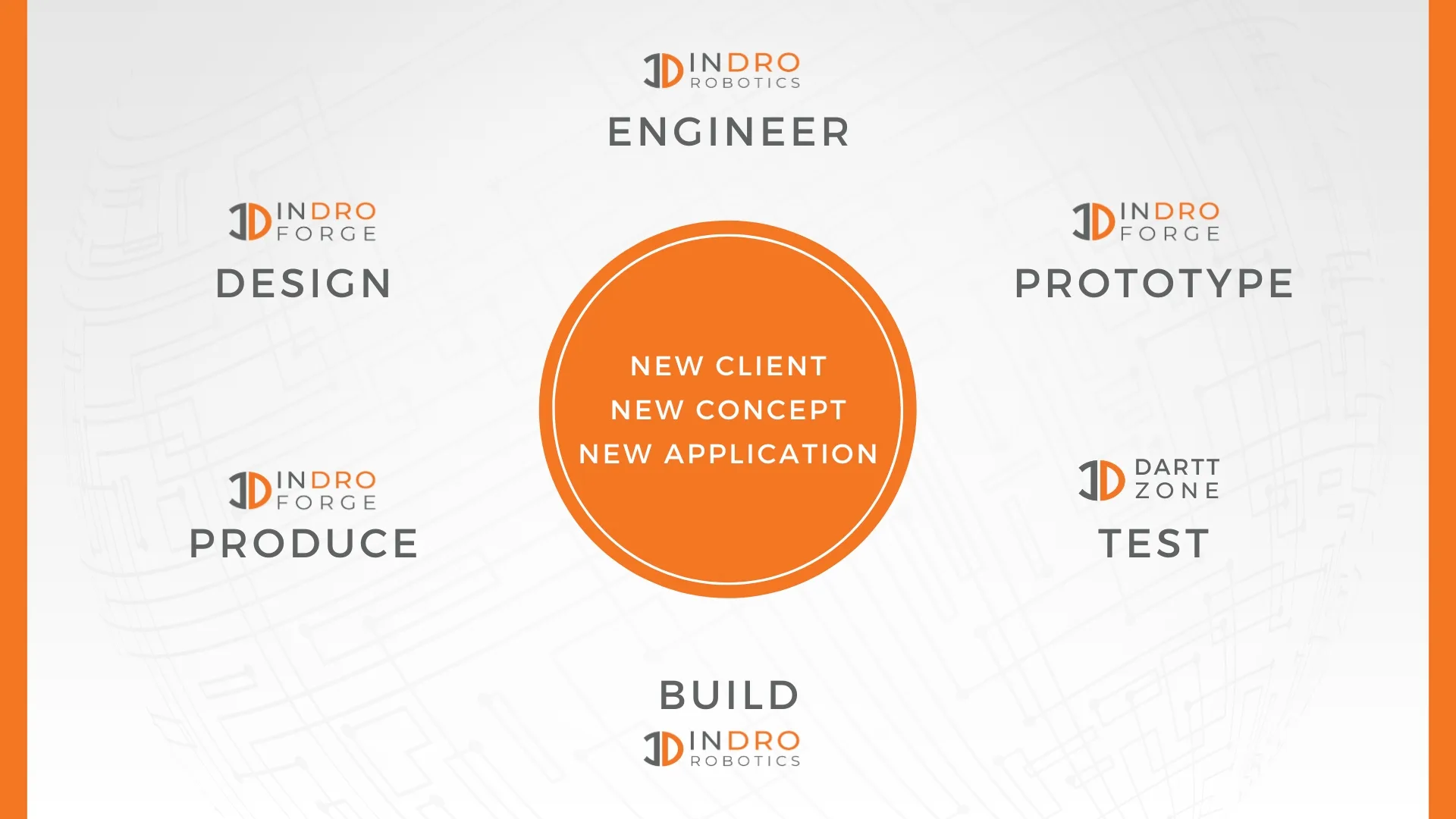

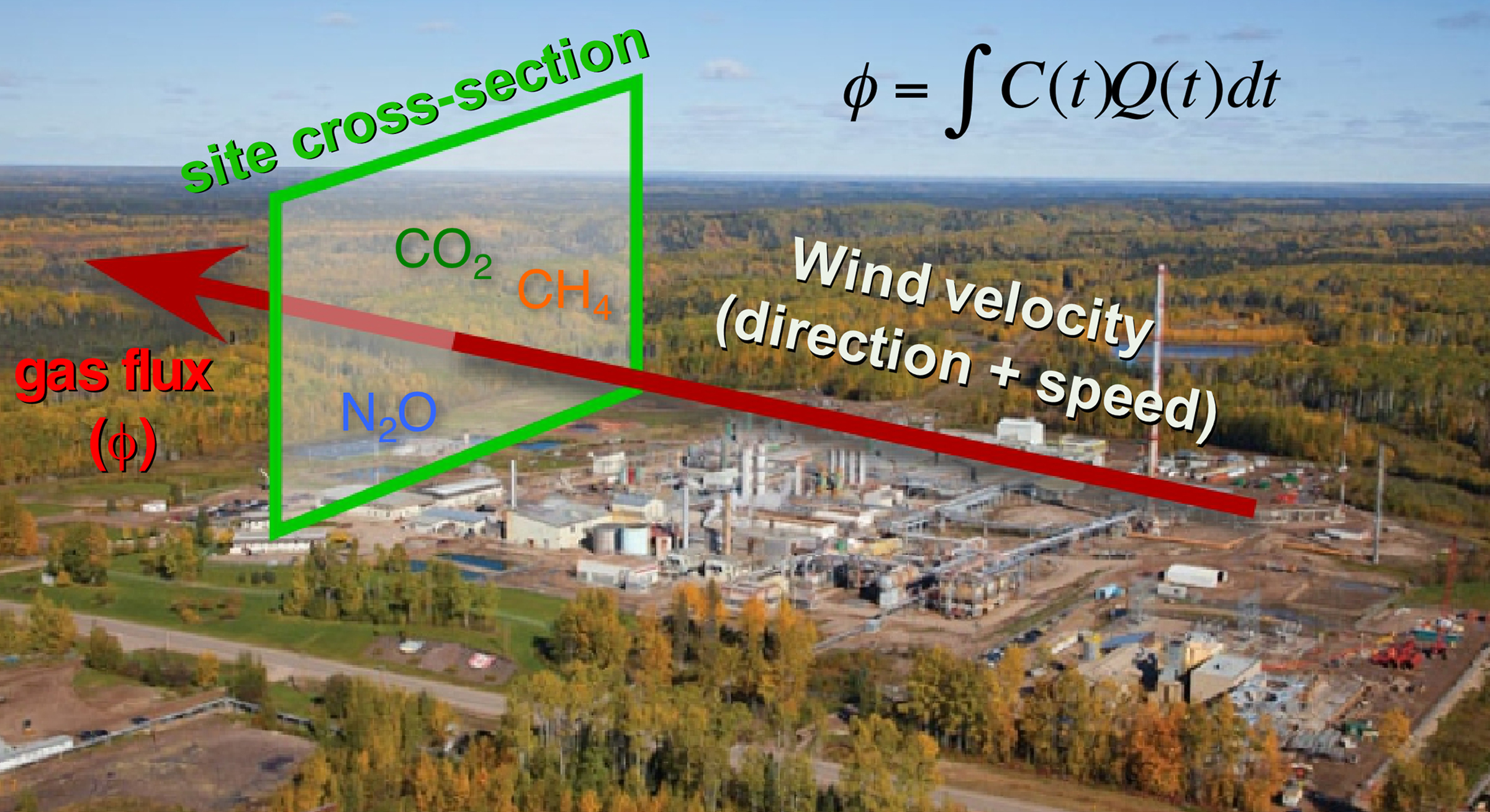

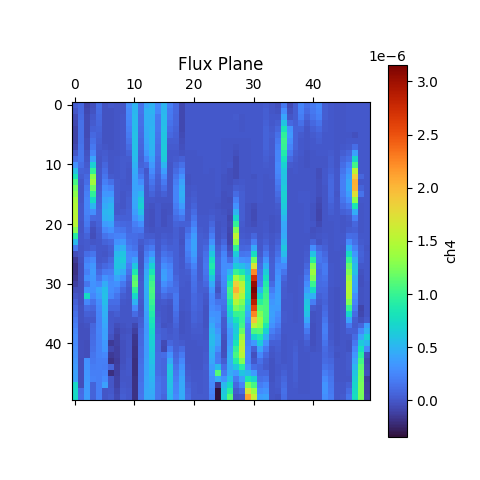

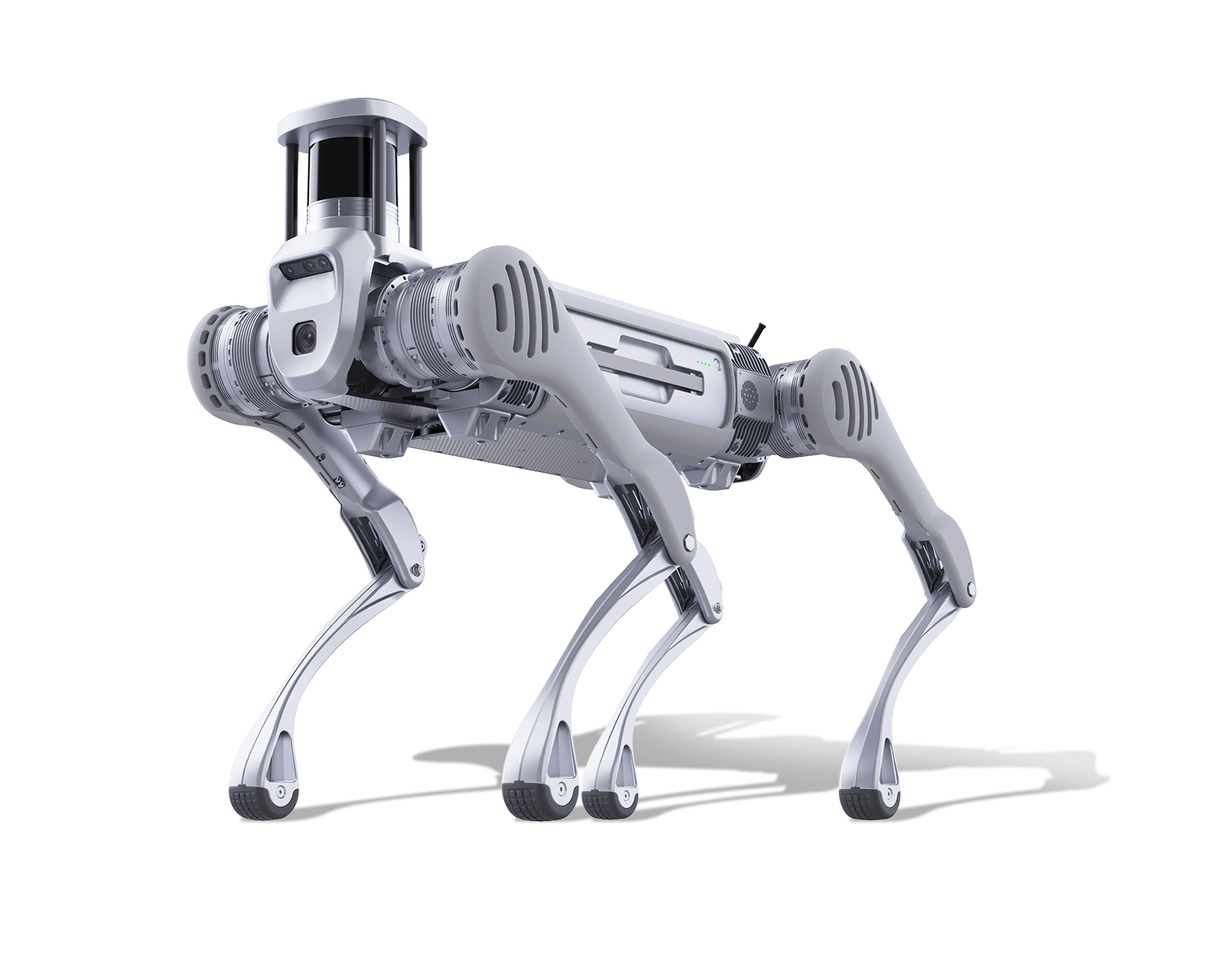

MULTI-STAGE ROBOTICS

This is where ground robots and aerial robots work in concert. And it’s one of the coming trends identified by Klassen.

“This is where you see ground robots and aerial robots working together to achieve different tasks. You can even have a drone…moving through a warehouse scanning tags and giving you live inventory management of that warehouse, which is a job that it turns out humans really hate to do,” she said.

“So it’s a great way to increase the retention of employees they want to keep, and give those dull, dirty, dangerous jobs to a robot.”

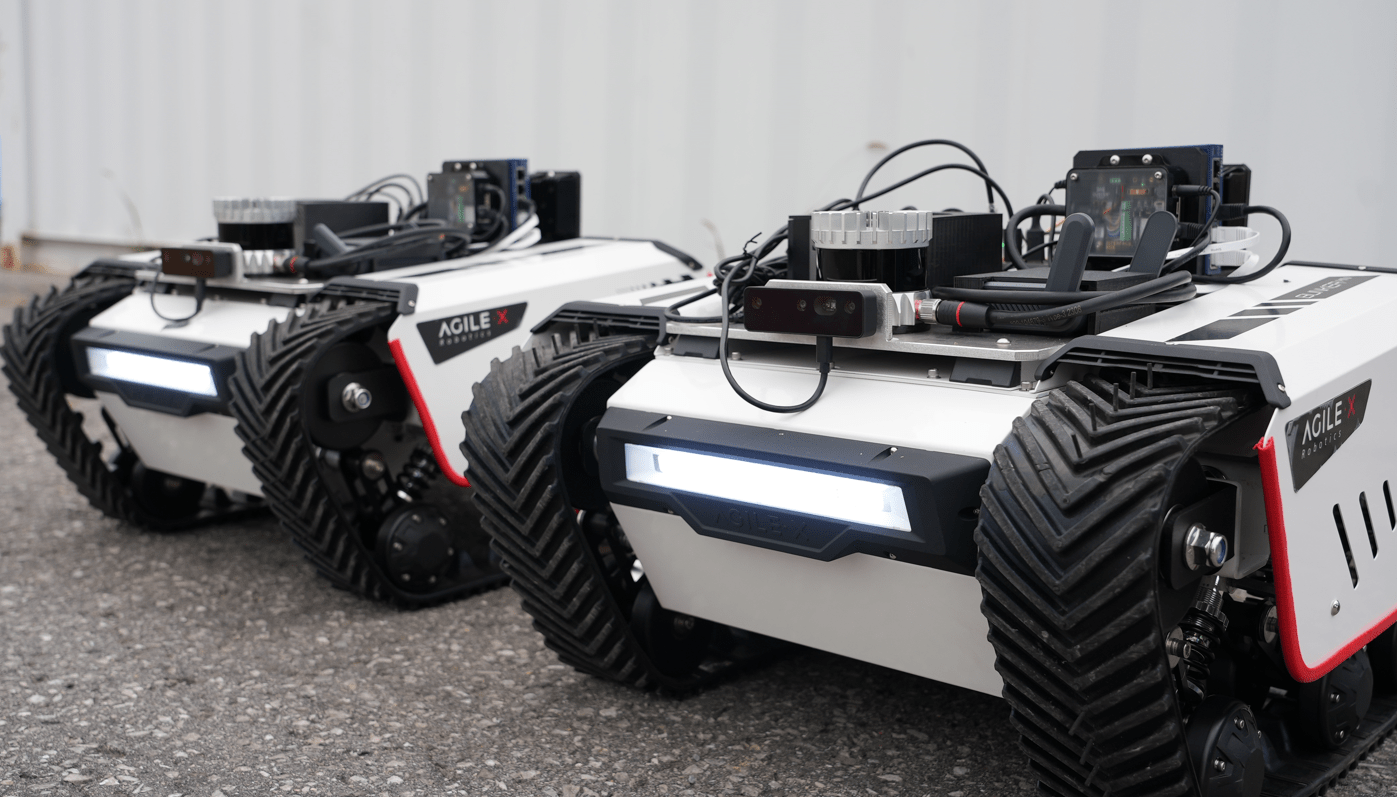

Below: Ground robots, like the InDro Robotics Sentinel, can work in conjunction with drones as a force multiplier

THE FUTURE

The ability to routinely fly Beyond Visual Line of Sight without the need for a Special Flight Operations Certificate from Transport Canada is something the industry has been focussed on for years. Such flights (and there are many carried out with SFOCs currently), permit drones to take on long-range tasks like delivery, inspection of railroads and pipelines – and much more. There’s great demand for such services, but the SFOC process slows things down.

Transport Canada understands this. But, as the federal regulator, it’s rightfully concerned about avoiding conflict with traditional aircraft, as well as people and property on the ground. But newer technology, including specialized Detect-and-Avoid sensors and software (along with parachutes), is paving the way for such flights to become routine.

In fact, Transport Canada is looking at revising Part IX of CARs in 2025 to permit many BVLOS flights without the need for an SFOC. There will also be provisions for drones up to 150 kilograms, meaning significant cargo could be delivered.

“I think it will be a while before you get your pizza delivered or Amazon deliveries via drone,” she says. “But routine BVLOS will be included in a regulatory package that we’re anticipating in 2025.”

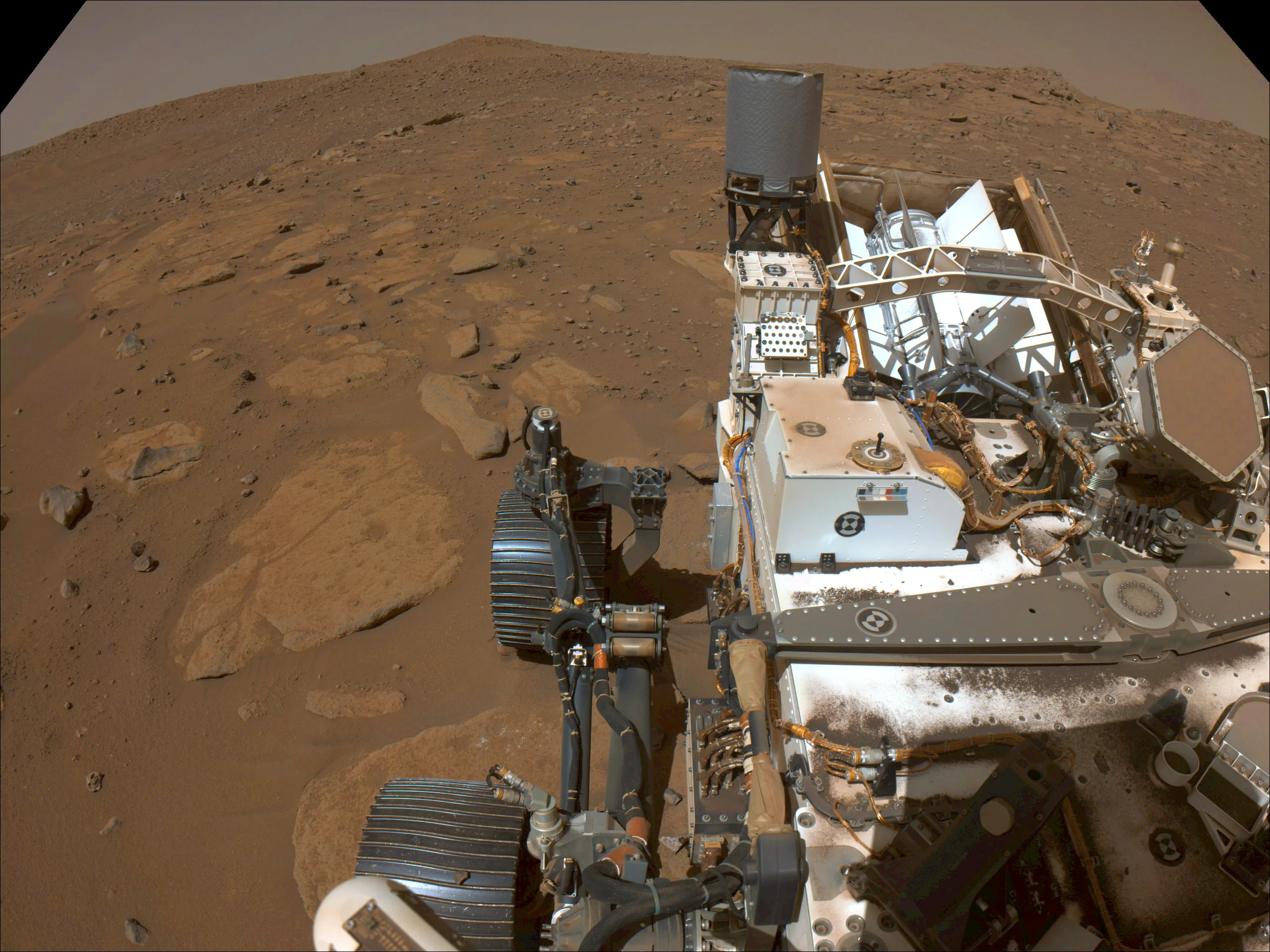

AAM

Another big piece of the future of aviation – globally – is the coming world of Advanced Air Mobility, or AAM. This is where transformative and largely carbon-neutral aircraft will be capable of shuttling people or cargo between locations that have until now been poorly served (or not served at all) by traditional aviation. For example, there are remote communities that do not currently have airports because the economic model just isn’t there. AAM could change that; the goal is for such services to be accessible and affordable – and the vast majority of these aircraft won’t require runways or the other infrastructure (fuel depots, control towers) typical of small airports.

Perhaps the most well-known coming application is that of an air taxi – a Vertical Takeoff and Landing (VTOL) aircraft that can transport people (or equivalent cargo). Such aircraft (many are currently in development and testing) would transit between Vertiports, small pads that will start appearing in major cities and nearby regions in the years to come. Though the regulations have not yet been ironed out, it’s anticipated (and the US Federal Aviation Administration is planning for) such vehicles to fly within specific corridors that keep them safely separated from the routes of traditional aircraft (including helicopters). Initial flights will be carried out by a human pilot actively piloting onboard (Human In the Loop), followed by a human pilot monitoring the flight onboard (Human On the Loop). Eventually, it’s anticipated that these aircraft will be fully autonomous (Human Out of the Loop), with a person simply monitoring the flight – still with the ability to intervene should a problem arise – from the ground.

In fact, we wrote recently that BC’s Helijet has placed the first orders for some of these aircraft – a signal that we are definitely on the cusp of this future. So remember that AAM acronym; it’s coming.

“This is a huge term…and it’s going to be very much the future of aviation,” said Klassen.

Below: The ALIA 250 eVTOL (electric Vertical Takeoff and Landing) aircraft, manufactured by US-based BETA Technologies, has been ordered by Helijet International. The vehicle transitions to forward, fixed-wing flight for greater efficiency once a sufficient altitude has been reached

THE PRESENT

We should mention that AAM is not solely about these larger aircraft; drones will be part of the AAM world, with a high degree of automation coordinating flights between these various automated aircraft.

In the meantime, the drone sector continues to grow, with many successful businesses across the country – ranging from large service providers like InDro Robotics right through to smaller one- and two-person operations. There are plenty of opportunities, with proper training and even a small investment, to start a company.

And that’s where FLYY comes in. Though Klassen only mentioned it in passing, she runs a successful online training operation that takes potential pilots with zero or minimal background with drones or aviation through all of the knowledge requirements to obtain their Basic or Advanced RPAS Certificate (including arranging the Flight Review required by Transport Canada to obtain that Advanced certification). We’ve previously written about this program here.

Klassen is the instructor of the course, which is arranged in logical, bite-sized steps (interspersed with her trademark humour) to keep aspiring pilots engaged. Klassen is passionate about sharing her expertise, and it shows in these courses. If you’d like to take the next step, you can check out her many course offerings here.

There are plenty of online offerings out there. But there’s only one we’re aware of where the person behind it has trained more than 10,000 drone pilots in Canada. Though Klassen doesn’t like to promote herself, we can state with authority that she is immensely respected in the field – both by professional drone operators and by the many people who’s worked with at Transport Canada.

“Our zero to hero package is $599 and includes both ground school, prep for your Flight Review, and the Flight Review itself. A DJI Mini 3 Fly More combo is like $850,” she said.

In other words, it won’t break the bank to gain the right knowledge and get flying. Plus, Klassen is currently working on Micro-Credential courses for students to pick up skills using specialised sensors and data analysis – the kind of skills that can land a job, but are difficult to obtain without one.

Below: Kate Klassen in a screengrab from her FLYY course

INDRO’S TAKE

Kate Klassen is the Training and Regulatory Specialist at InDro Robotics. So you’d expect we’d have good things to say about her. The reality is, we’d have good things to say about her regardless of where she worked. She is a the very definition of a subject matter expert, and she loves nothing more than sharing her knowledge and helping to shape the future of aviation in Canada. (Well, that’s not quite true: She has two young children and a husband who collectively make aviation and drones her second love.)

“As expected, Kate covered a lot of ground in her presentation – and did a fantastic job of providing a clear look at the state of the industry, along with where it’s headed,” says InDro Robotics CEO Philip Reece.

“Klassen is a true professional in every sense of the word. We feel fortunate that she’s on Team InDro, where her vast regulatory knowledge of both traditional aviation and drones is immensely helpful both to our team – and the drone sector at large.”

If you’d like to download Kate’s presentation, you can do so here. And if you’re an educational institute, or a business considering training with multiple students, Klassen is always happy to discuss a break on price. You can contact her directly here.