By Scott Simmie

Back in 2022 we officially took the wraps off Sentinel – a workhorse robot aimed at remotely inspecting assets like electrical substations.

Before we even designed and built Sentinel, our engineering and sales team put a lot of thought into what would need to go into such a robot. We knew, first and foremost, it had be rugged and capable regardless of terrain. It had to be nearly impervious to inclement weather. It had to be capable of transmitting even dense data from hundreds or thousands of kilometres away from the client. Plus, it had to be equipped with state-of-the-art sensors. Oh yes, it also needed to perform self-diagnostics and send back an easy to read overall health report.

And then our team at Area X.O got to work.

Below: Sentinel

INVENT, ENHANCE, DEPLOY

You may have heard that phrase before. It’s a quote from Founder and CEO Philip Reece that succinctly encapsulates what InDro does. It has since become our tagline, and if you see us at a convention you’ll see it on our branding.

The reason we emphasize this now is because InDro remains committed to this ethos. Once we have a product out in the field, we don’t rest on our laurels. We gather learnings from our testing, deployments, and – most importantly of all – our clients to see if we can make an already good product better.

Sentinel featured high-power onboard compute, a 30x optical PTZ camera (complete with wiper!), a thermal sensor and more. It also carried the ROS1 software library onboard which – among other things – allowed Sentinel to instantly recognise any new sensors that were added or replaced. It came equipped with a high-speed modem for remote teleoperations. And it had a pretty good version of our own InDro Autonomy stack.

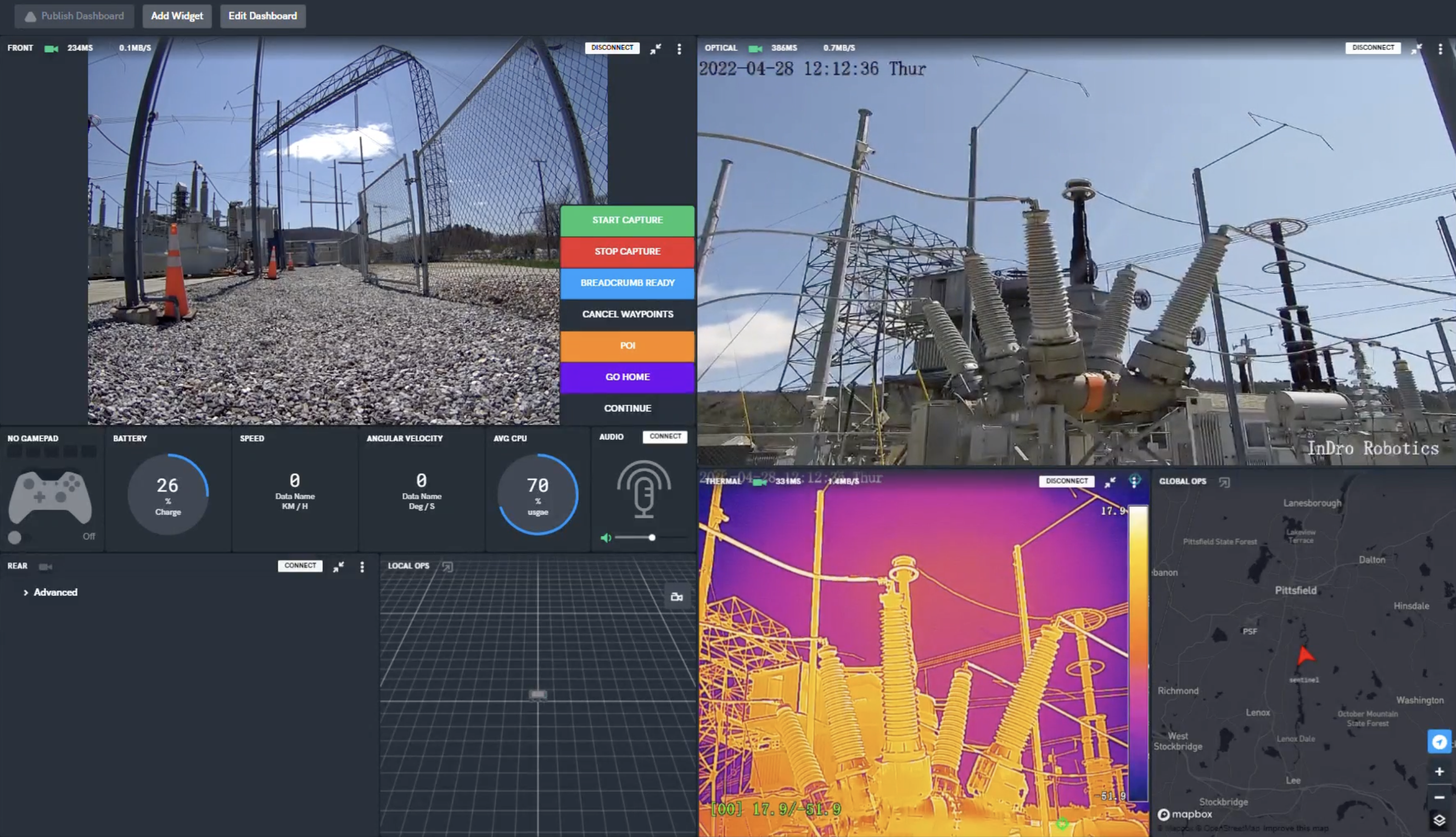

During a demonstration from Washington State we connected over a 5G network to Area X.O in Ottawa. The two locations were more than 4100 kilometres apart. At the Bellevue end, we had an Xbox controller connected to a laptop. That laptop was logged into a third-party console for remote operations.

At the other end, Sentinel was awaiting instructions. We showed several people the basics of how to operate (and it doesn’t get more intuitive than an Xbox controller) and let them take a spin. You might well think, given the distance involved, there would have been a perceptible lag. There wasn’t (I was there). The response was so instantaneous it was almost like playing a video game. Plus, realtime data – including a video feed – was coming in from Sentinel’s sensors.

THE EPRI DEPLOYMENT

Testing robots – particularly robots like Sentinel – in a real-world environment is crucial. And, since Sentinel was designed for the remote inspection of critical assets like electrical substations, we caught the attention of EPRI – the Electric Power Research Institute. The non-profit organization is constantly doing research, collaborating with more than 450 private companies across 45 countries globally.

EPRI has multiple research facilities, including one in Lenox, Massachusetts. This particular location features an electrical substation that can be energised, de-energised – and can even simulate rain for testing purposes. So we took Sentinel down there and put it through its paces. We ran it through every variation of testing they could throw at it, including nighttime missions (with the substation both energised and de-energised) as well as with and without rain in each of those scenarios. (Yes, we did daytime missions as well.)

The purpose was to see how well Sentinel could perform in that very much real-world setting. It did very well – though we aso learned some lessons. We discovered that gravel could occasionally get caught between the gears and the treads. And, more importantly, we found that capturing and delivering all that data while doing remote ops put a crushing demand on the compute (a Jetson Xaiver NX).

“We were maxing out the CPU,” recalls Head of R&D Sales Luke Corbeth, who was on that mission. “We were at pretty much 99 per cent usage.”

Over the course of subsequent deployments and testing, we began to explore ways to improve Sentinel.

Below: Data flows through the third-party console we were using at the time to monitor missions

UPGRADED INTERIOR, EXTERIOR

We’ve always had a consistent vision for Sentinel and its use-cases.

“The concept has basically gone unchanged since our initial vision,” says Corbeth. “We envisioned certain industries with an emphasis on the value of preventative maintenance. That has remained the focus.”

But as we encountered new environments and challenges, we worked on ways to improve the build. We are now taking advantage of the latest in AI processing, giving these robots the NVIDIA Jetson AGX Orin Developer Kit for compute. It’s capable of up to 275 trillion operations per second (TOPS) – and is a huge leap forward in compute and AI recognition. Plus, you can throw literally everything at it and it doesn’t break a sweat.

“We’re now able to operate – with all data streaming – at about 30 to 40 per cent of the CPU’s capacity,” says Corbeth.

An optional platform upgrade brings us to the Bunker Pro, which has better weather protection (including skirts that prevent gravel from getting stuck) and longer run time. We moved to the latest models of PTZ and thermal cameras to ensure exceptional resolution and the best imagery in low-light situations. We integrated more pinhole cameras for 360° situational awareness and added a second depth perception camera. We can also add a range finder and two hemispherical LiDAR units, pending client needs. (There’s also the option of safety LiDAR units if Sentinel is deployed around people.)

And that’s just for starters. In addition, InDro’s engineering team can add:

- New connectivity module for greater bandwidth and lower latency

- Improved GPS and IMU units

- The latest InDro Autonomy stack

All of these capabilities ensure Sentinel can operate with precision in unfamiliar and GPS-denied environments. It returns to base and recharges wirelessly without any mechanical connection (thus avoiding a potential point of failure). It can capture flawless digital twins of entire facilities.

And InDro is in control of all facets of production.

“With the introduction of InDro Forge, we’ve been able to do all of the design and manufacturing in-house,” says Corbeth.

Below: Sentinel combines brains with brawn

MISSION PLANNING

Remember how we mentioned originally operating Sentinel via a third-party console? Well, despite getting pretty low latency we found some things were lacking. We wanted a more intuitive and powerful system for controlling Sentinel and setting up autonomous missions. We also wanted a console with bulletproof security.

So we built one. InDro Controller both improves the user experience and adds more power and customization features for the client. We asked Luke to walk us through how easy it is for a client to plan a mission.

“So the robot will always begin its mission starting in the doghouse where it’s actively wirelessly charging, ready to deploy at a moment’s notice with full battery. Deployments can be automated and autonomous, or manually operated,” he explains.

Most clients prefer to have autonomous missions. And InDro is happy to help set up optimal mission planning, with specific repeatable actions at various waypoints. The exceptional AI and machine vision onboard means that Sentinel can not only recognise a gauge – it can understand the reading.

“So we help create the most efficient and safest route for the robot to follow. And at each of its specific waypoints, it’s capturing high-resolution photos, video or thermal data. It will remember, for example, to not only stop but to adjust the camera and zoom in on a specific predetermined asset. You’ll get actionable data with every mission,” adds Corbeth.

Watch both Sentinel and InDro Controller at work in the video below

INDRO’S TAKE

There are even more enhancements on the way for Sentinel that we didn’t explore in this post. If you’re curious, you can check out even more features here.

“Sentinel is an exceptionally well-engineered product – where every design decision was made with the client in mind,” says InDro Robotics Founder and CEO Philip Reece. “It has already drawn attention from those seeking a cutting-edge solution to autonomous remote inspections. A US client just purchased several for precisely that use-case, and we’ll be completing those builds shortly.”

Interested in a demo? Get in touch with Luke Corbeth and he’ll set you up.