By Scott Simmie

There’s nothing we like more than success stories – especially when technology is involved.

So we’re pleased to share news that a team of bright young engineers from the University of Pennsylvania were the winners of a prestigious competition sponsored by SICK, the German-based manufacturer of LiDAR sensors and industrial process automation technology.

The competition is called the SICK TiM $10K Challenge. The competition involves finding innovative new uses for the company’s TiM-P 2D LiDAR sensor. Laser-based LiDAR sensors scan the surrounding environment in real-time, producing highly accurate point clouds/maps. Paired with machine vision and AI, LiDAR can be used to detect objects – and even avoid them.

And that’s a pretty handy feature if your robot happens to an autonomous garbage collector. We asked Sharon Shaji, one of five UPenn team members (all of whom earned their Masters in Robotics this year), for the micro-elevator pitch:

“It’s an autonomous waste collection robot that can be used specifically for cleaning outdoor spaces,” she says.

And though autonomous, it obviously didn’t build itself.

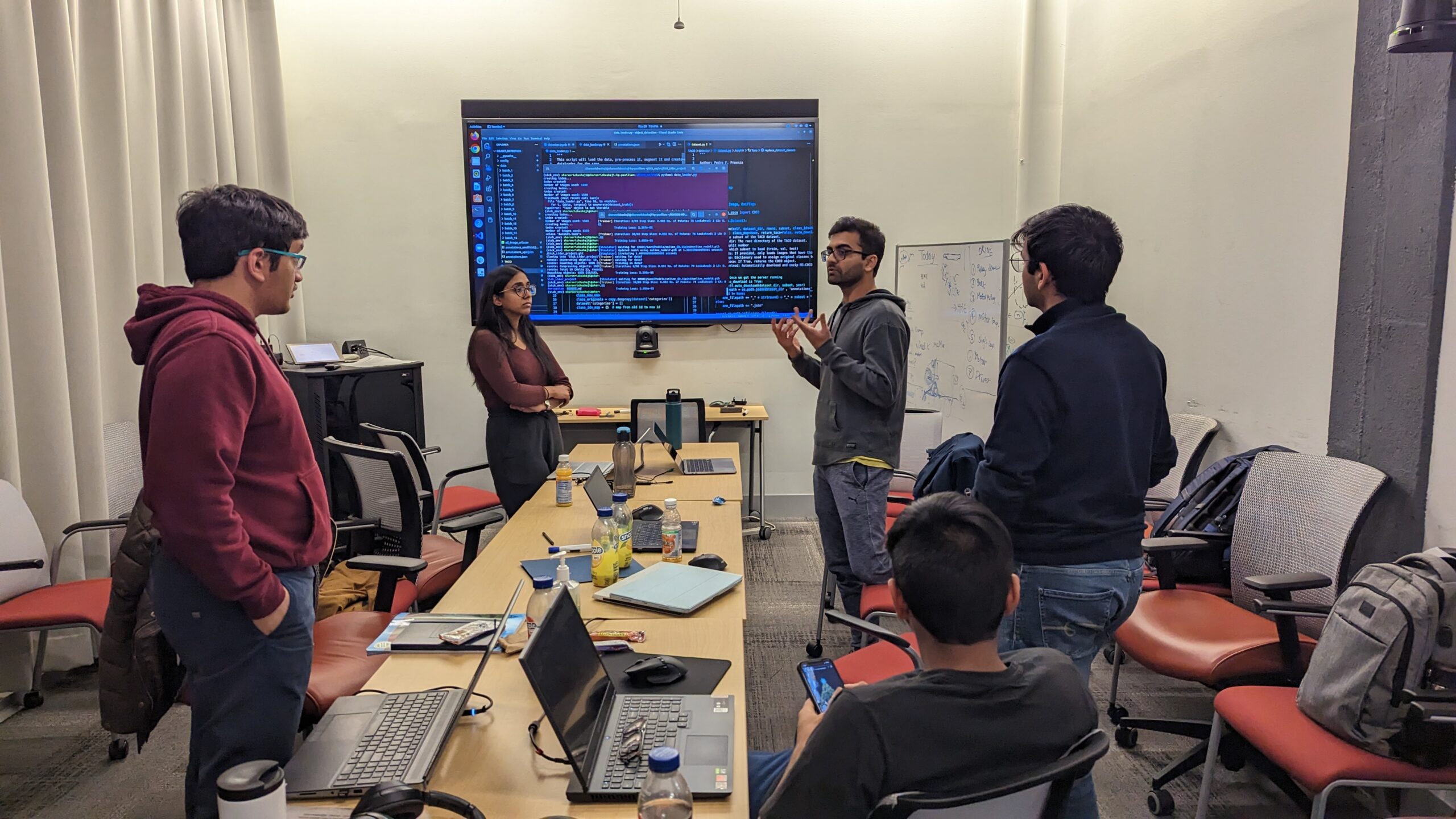

Below: Members of the team during work on the project.

THE COMPETITION

When SICK announced the contest, it had a very simple criteria: “The teams will be challenged to solve a problem, create a solution, and bring a new application that utilizes the SICK scanner in any industry.”

SICK received applications from universities across the United States. It then whittled those down to 20 submissions it felt had real potential, and supplied those teams with the TiM-P 270 LiDAR sensor free of charge.

Five students affiliated with UPenn’s prestigious General Robotics, Automation, Sensing and Perception Laboratory, or GRASP Lab, put in a team application. It was one of three GRASP lab teams that would receive sensors from SICK.

That Lab is described here as “an interdisciplinary academic and research center within the School of Engineering and Applied Sciences at the University of Pennsylvania. Founded in 1979, the GRASP Lab is a premier robotics incubator that fosters collaboration between students, research staff and faculty focusing on fundamental research in vision, perception, control systems, automation, and machine learning.”

Before we get to building the robot, how do you go about building a team? Do you just put smart people together – or is there a strategy? In this case, there was.

“One thing we all kept in mind when we were looking for teammates was that we wanted someone from every field of engineering,” explains Shaji. In other words, a multidisciplinary team.

“So we have people from the mechanical engineering background, electrical engineering background, computer science background, software background. We were easily able to delegate work to every person. I think that was important in the success of the product. And we all knew each other, so it was like working with best friends.”

GENESIS

And how did the idea come about?

Well, says the team (all five of whom hopped on a video call with InDro Robotics), they noticed a problem in need of a solution. Quite frequently on campus – and particularly after events – they’d noticed that the green space was littered. Cans, bottles, wrappers – you name it.

They also noticed that crews would be dispatched to clean everything up. And while that did get the job done, it wasn’t perhaps the most efficient way of tackling the problem. Nor was it glamorous work. It was arguably a dirty and dull job – one of the perfect types of tasks for a robot to take on.

“Large groups of people were coming in and manually picking up this litter,” says Shaji.

“And we realised that automation was the right way to solve that problem. It’s unhygienic, there are sanitation concerns, and physically exhausting. Robots don’t get tired, they don’t get exhausted…we thought this was the best use-case and to move forward with.”

Below: Working on the mechanical side of things

GETTING STARTED

You’d think, with engineers, the first step in this project would have been to kick around design concepts. But the team focussed initially on market research. Were there similar products out there already? Would there be a demand for such a device? How frequently were crews dispatched for these cleanups? How long, on average, does it take humans to carry out the task? How many people are generally involved? Those kinds of questions.

After that process, they began discussing the nuts and bolts. One of the big questions here was: How should the device go about collecting garbage? Specifically, how should it get the garbage off the ground?

“Cleaning outdoor spaces can vary, because outdoor spaces can vary,” says team member Aadith Kumar. “You might have sandy terrain, you might have open parks, you might have uneven terrain. And each of these pose their own problems. Having a vacuum system on a beach area isn’t going to work because you’re going to collect a lot of sand. The vision is to have a modular mechanism.”

A modular design means flexibility: Different pickup mechanisms would be swappable for specific environments without requiring an entirely new robot. A vacuum system might work well in one setting, a system with the ability to individually pick items of trash might work better somewhere else.

The team decided their initial prototype should focus on open park space. And once that decision was made, it became clear that a brush mechanism, which would sweep the garbage from the grass into a collection box, would be the best solution for this initial iteration.

“We considered vacuum, we considered picking it up, we considered targeted suction,” says Kumar. “But at the end of the day, for economics, it needed to be efficient, fast, nothing too complicated. And the brush mechanism is tried and tested.”

Below: Work on the brush mechanism

SAUBERBOT

The team decided to call its robot the SauberBOT. “Sauber” is the German word for “clean”. But that sweeping brush mechanism would be just one part of the puzzle. Other areas to be tackled included:

- Depth perception camera for identifying trash to be picked up

- LiDAR programmed so that obstacles, including people, could be avoided

- Autonomy within a geofenced location – ie, the boundaries of the park to be cleaned

There was more, of course, but one of the most important pieces of the puzzle was the robotic platform itself: The means of locomotion. And that’s where InDro Robotics comes in.

THE INDRO CONNECTION

Some team members had met InDro Account Executive Luke Corbeth earlier in the year, at the IEEE International Conference on Robotics and Automation, held in Philadelphia in 2022. Corbeth had some robotic platforms from AgileX – which InDro distributes in North America – at the show. At the time the conference took place, the SICK competition wasn’t yet underway. But the students remembered Corbeth – and vice versa.

Once the team formed and entered the contest, discussions with InDro began around potential platforms.

The team was initially leaning toward the AgileX Bunker – a really tough platform that operates with treads, much like a tank. At first glance, those treads seemed like the ideal form of locomotion because they can operate on many different surfaces.

But Luke steered them in a different direction, toward the (less-expensive) Scout 2.0.

“He was the one who suggested the Scout 2.0,” says Udayagiri.

“We actually were thinking of going for the Bunker – but he understood that for our use-case the Scout 2.0 was a better robot. And it was very easy to work with the Scout.”

Corbeth also passed along the metal box that houses the InDro Commander. This enabled the team to save more time (and potential hassle) by housing all of their internal components in an IP-rated enclosure.

“I wanted to help them protect their hardware in an outdoor environment,” he says. “They had a tight budget, and UPenn is a pretty prominent robotics program in the US.”

But buying from InDro begs the question: Why not build their own? A team of five roboticists would surely be able to design and build something like that, right? Well, yes. But they knew they were going to have plenty of work on their own without having to build something from scratch. Taking this on would divert them from their core R&D tasks.

“We knew we would do it in a month or two,” says the team’s Rithwik Udayagiri. “But that would have left us with less time for market research and actually integrating our product, which is the pickup mechanism. We would have been spending too much time on building a platform. So that’s why we went with a standalone platform.”

It took a little longer than planned to get the recently released Scout 2.0 in the hands of the UPenn team. But because of communication with Luke (along with the InDro-supplied use of the Gazebo robot simulation platform), the team was able to quickly integrate the rest of the system with Scout 2.0 soon after it arrived.

“The entire project was ROS-based (Robot Operating System software), and they used our simulation tools, mainly Gazebo, to start working on autonomy,” explains Corbeth. “Even though it took time to get them the unit, they were ready to integrate their tech and get it out in the field very quickly. That was the one thing that blew me away was how quickly they put it together.”

It wasn’t long before SauberBOT was a reality. The team produced a video for its final submission to SICK. The SauberBOT team took first place, winning $10,000 plus an upcoming trip to Germany, where they’ll visit SICK headquarters.

Oh, and SauberBOT? The team says it cleans three times more quickly than using a typical human crew.

Here’s the video.

A CO-BOT, NOT A ROBOT

Team SauberBOT knows some people are wary of robots. Some believe they will simply replace human positions and put people out of work.

That’s not the view of these engineers. They see SauberBOT – and other machines like it – as a way of helping to relieve people from boring, physically demanding and even dangerous tasks. They also point out that there’s a labour shortage, particularly in this sector.

INDRO’S TAKE

We’re obviously pleased to have played a small role in the success of the UPenn team. And while we often service very large clients – including building products on contract for some global tech giants – there’s a unique satisfaction that comes from this kind of relationship.

“It’s very gratifying,” says Corbeth. “In fact, it’s the essence of what I try to do: Enable others to build really cool robots.”

The SauberBOT is indeed pretty cool. And InDro will be keeping an eye on what these young engineers do next.

“The engineering grads of today are tomorrow’s startup CEOs and CTOs,” says InDro Robotics Founder/CEO Philip Reece.

“We love seeing this kind of entrepreneurial spirit, where great ideas and skills lead to the development of new products and processes. In a way, it’s similar to what InDro does on a larger scale. Well done, Team SauberBOT – there’s plenty of potential here for a product down the road.”

If you’ve got a project that could use a robotic platform – or any other engineering challenge that taps into InDro’s expertise with ground robots, drones and remote teleoperations – feel free to get in touch with Luke Corbeth here.