By Scott Simmie

At InDro Robotics, our engineering team is known for being creative. That’s how we come up with innovative solutions – whether they’re inventions like InDro Commander or InDro Controller, or designing and integrating a ground-up robotic solution based on a client’s needs. That’s technical creativity – and every member of the InDro team has that skill in spades.

But there’s another type of creativity – one that involves a truly artistic sense of design; the ability to visualise a beautiful but functional form, design it, and bring it to life. When it comes to those kinds of tasks, we inevitably turn to InDro Forge Project Manager Stephan Tzolov. He’s truly gifted in this realm.

What makes his story particularly interesting is that he initially had plans to become a doctor – and studied biochemistry at Carleton University en route to that goal. He found the topic fascinating, but it was also somewhat dry. It involved (as you can imagine) a lot of memorisation of cold, hard facts – followed by more cold, hard facts. By the time he was in his third year, he was starting to wonder if this truly was his passion.

“I was pretty close to graduating, and I thought: ‘Oh my gosh, this isn’t it.’ It was fascinating, but it wasn’t fulfilling,” he recalls.

That’s when he started doing some soul-searching, and sat down with a good friend. In a nutshell, that friend told him something Tzolov intuitively knew: “‘You’re not built for medicine – you’re too creative for that.’ And then he showed me Industrial Design, and it really was a perfect fit, kind of mixing engineering with creativity.

“I thought: I’d rather be a little unhappy now than unhappy forever. So I pulled the plug.”

He switched to Industrial Design, learning everything from the basics (like how to sketch out an idea) through to a full complement of rendering skills and manufacturing techniques. He loved it, immersing himself in acquiring every possible skill to take something from an idea to a real-world product.

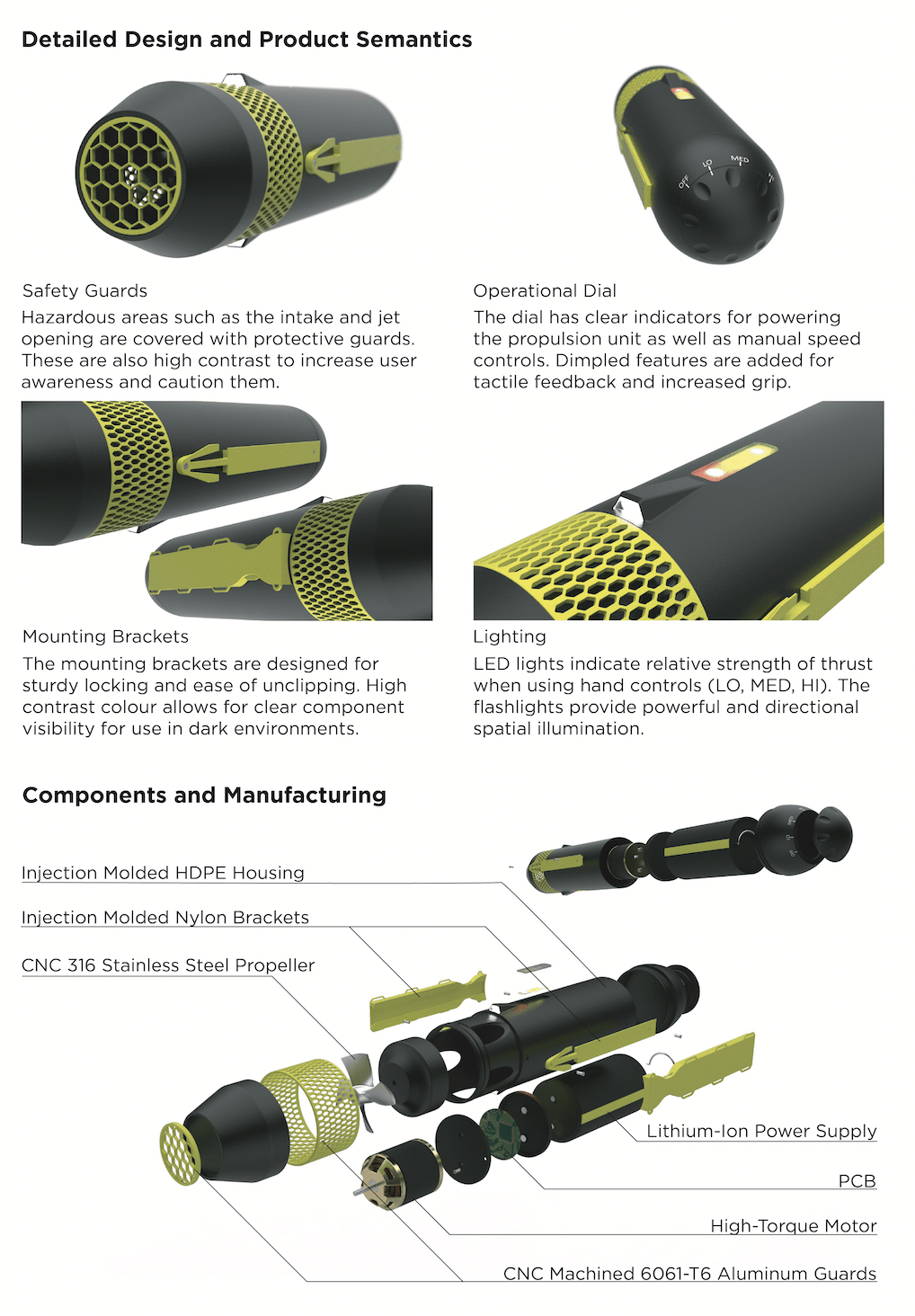

His eight-month capstone project in the course (completed during the peak of the pandemic) was designing and then manufacturing a fully functional propulsion system for SCUBA divers. These images are taken from his graduate presentation. (No, that’s not Stephan in the underwater shot – though people commonly make that assumption. In fact, Stephan deliberately chose someone who kind of looked like him for the image.)

DESIGN CAREER COMMENCES

Stephan’s work at Carleton was impressive. So impressive, that one of his professors (who had also become a mentor) told him he had a job waiting the moment he was done school. And so Stephan jumped in at Ottawa’s Studio 63, a small but award-winning design studio that, says its website, “helps businesses and entrepreneurs make some of the most futuristic and innovative products on the planet.”

If you think about it, virtually every single consumer product in the world (and, potentially, on other planets) involves Industrial Design. Whether it’s a coffee mug or a passenger jet, someone with Industrial Design chops is involved. At Studio 63, Stephan was involved in helping to design everything from high-end audio equipment and automobile features right through to – wait for it – sex toys. Most of these tasks involved not only working with clients on the form factor, where he could unleash his creativity with spectacular designs and renders, right through to electronics and integration.

Then, luckily for InDro, there was a fortuitous bit of synchronicity. InDro Engineering Lead Arron Griffiths knew the head of Studio 63. He had a design project for them which required a high-end shell for a very large ground robot. That robot was being produced for one of the world’s biggest tech companies, so it had to be *perfect.* (We’d love to tell you more, but can’t due to NDA).

Long story short, Stephan produced a shell so sleek and curvaceous and beautiful that it would look right at home in a Batman movie.

“The client loved it,” says Stephan. (In fact, this project turned into a multi-year contract with many of these robots produced, each one covered in that slippery, stealthy grey shell.)

HARD BODY VS SURFACE

In the engineering world, there are basically two styles of design: hard body and surface.

“So hard body – think of cubes and hard shapes,” explains Tzolov. “Surface modelling is more like organic, it’s more sculptural, it’s more soft. Think of the exterior of a car – it flows, it has a shape, there’s rarely a right angle. It’s all curvature.”

And that shell? Its design flows like a liquid.

Stephan’s abilities and personality impressed Griffiths. Right around that time, things had slowed a bit at Studio 63, partly due to the ongoing pandemic. Stephan’s boss gave him his blessings if he wanted to look around. Soon there was a conversation directly with Griffiths – who saw an ideal fit.

“Stephan was exactly the person we were looking for,” he says. “His shell design was outstanding, and he had exceptional knowledge of production techniques. Plus, he’s just a great person to work with.”

And so, two years ago, Stephan made the jump to InDro, hired as Production Engineer. His skillset quickly became apparent to the entire team. He was not only stellar at rendering, but knew how to take those renders to reality.

Below: A couple of Stephan’s renders – A B1 robot with the InDro Backpack, and an InDro holiday greeting card

THE FORGE CONNECTION

When InDro took over operations of what was known as the Bayview Yards Prototyping Lab (in collaboration with Invest Ottawa), our manufacturing capabilities took a quantum leap. InDro Forge is stocked with state-of-the-art tools for additive and subtractive manufacturing. We have a CNC machine, an OMAX water jet table, the BigRep ONE large format 3D printer – and a host of other machines and capabilities. Whether it’s producing prototypes or parts for clients, or manufacturing components for InDro Robotics projects, this facility has it all.

It was a perfect fit for Stephan. He already had expertise in multiple manufacturing techniques, and was eager to learn more. He moved over to the Forge facility with the new job title of Applications Engineer, and has since been promoted to Project Manager. He’s now overseeing the Big Picture, often working on the design and fabrication of parts and the integration of electronics and sensors, frequently hand-in-hand with the engineering team at Area X.O.

“The project management side covers things like organizing tasks, keeping keeping track of people’s capacity and who’s available for what at what time. So basically integration is what I’m covering. And when I delegate, I’m often delegating to myself.”

All, while working closely with Lead Engineer Arron Griffiths.

“There’s a lot of cross-pollination,” says Stephan.

But don’t worry, despite his promotion he still gets his hands dirty with all of the tools at Forge (though his hands stay pretty clean while carrying out renders).

ONE ROBOT STANDS OUT

Stephan has been integral to a lot of projects. That shell for the tech robot remains his highlight.

But one other project also stands out. Prior to Tzolov’s transition to InDro Forge, a client (another global tech company), wanted InDro to produce a robot capable of navigating in spaces crowded with people. It would be deployed in crowded spaces like boardwalks, malls – anywhere there were people around. It was part of a long-term project at that company about autonomous navigation and the human-robot interface. It also had to be tall, with sensors at roughly head height.

Stephan immediately got to work on the renders, as the client was under a tight deadline. But then something happened that made that deadline even more pressing: Engineering Lead Griffiths was taking a couple of weeks off to get married. And he had a tiny request before leaving: Could you please have the robot finished by the time I return?

The task would fall to Stephan, who would be lead on the project, working in conjunction with technologist Ujas Patel. The pair had worked closely together on the aforementioned large ground robot, and the synergy between the two of them was spectacular.

“We had worked shoulder-to-shoulder on that project and were very familiar with each other’s workflow,” says Stephan. “It’s almost like we communicate telepathically.”

Though he’s not a software expert, Stephan had the manufacturing and electro-mechanical chops for the task. In conjunction with Patel’s considerable skills, the two worked long (and we mean long) hours while Arron was away. The project had to be done. And, when the newlywed arrived back at the office, it was. What’s more, the client was unbelievable happy when it received the end product. Head of R&D Sales Luke Corbeth, who had put the deal together, received an absolutely glowing email from the client: They loved the design, the form factor, the functionality. It was, they said, perfect.

“That was just the cherry on top,” says Tzolov.

Below: Stephan working on the robot, under the gun. Image two: Stephan with Area X.O colleagues Ujas Patel (left) and technologist Tirth Gajera (also known in the shop as “T”)

A PERFECT FIT

Stephan Tzolov has had quite the journey. (If we want to go way back, he was born in Canada but spent his early years in Bulgaria. When he started school in Canada he spoke only Bulgarian.)

But we’re talking here more about his recent journey – that soul-searching decision to leave medicine and enter Industrial Design. It was exactly the right choice for Tzolov. His enthusiasm for seeing his creations come to life gives him tremendous satisfaction. He literally beams when describing how much he loves what he does.

“It’s freaking awesome,” he says.

“It’s so interesting when you have an idea – it almost becomes its own weirdly living thing. Creating something robotic on a design, mechanical and electrical level that lives and breathes wasn’t something I thought of doing before coming on board with InDro. I absolutely love making things. So this job is really cool. Actually, it’s the coolest ever.”

And those long hours that some projects involve? Not a problem. InDro recognises – and rewards – hard work.

“Arron has always taken care of me when it comes to work. It’s like, you work hard – and you get to rest hard. You put in crazy overtime and it gets noted, and you’re compensated in one way or another. There’s a mutual respect and appreciation for one another at InDro. I have never complained to my partner about work politics or interpersonal stuff, because there’s never any issue. Everyone here is on the same page.”

Below: That crowd-avoiding robot, completed to an exceedingly tight timeline

INDRO’S TAKE

Like all InDro employees, Stephan Tzolov is a valued team member. And like his colleagues, he has specific skills that contribute immensely to what InDro produces. We plan on profiling other members of Team InDro in the future, but wanted to take a moment to acknowledge Stephan’s particularly creative skillset.

“Everyone at InDro has specific strengths and knows how to work well in a team environment toward our common goals,” says InDro Robotics Founder and CEO Philip Reece. “That’s one of the things I believe truly sets InDro apart. Stephan’s creativity, along with his manufacturing knowledge and electrical and mechanical capabilities are a valuable asset to InDro Forge and InDro Robotics as a whole. I’m sure he would have made a great doctor, but we’re definitely pleased he opted for that career change.”

Every single InDro employee brings something special to the company. This time, it was Stephan’s turn to be highlighted. We look forward to introducing you to other members of Team InDro down the road.