By Scott Simmie

We always like to pause at this time of the year and reflect; to look back on the year that was and celebrate the milestones and innovations achieved by Team InDro. It’s an exercise that’s always both satisfying and somewhat surprising, as we routinely forget just how much we managed to pack in.

2024 was a very good year for InDro Robotics, as well as InDro Forge – our rapid prototyping and limited production run facility based at Ottawa’s Bayview Yards.

Before we get into outlining all the specific projects and breakthroughs we’ve enjoyed during the year, it’s worth mentioning that while the focus of this story will largely be the engineering work carried out at our Area X.O research and development headquarters, InDro Robotics also has employees elsewhere in Canada, including Toronto, London, Alberta and British Columbia.

And – as you’ll see – they do cool stuff, too.

Below: The newest iteration of our Sentinel inspection workhorse

THE BIG PICTURE

The high-level view is a good one, and it’s this: InDro excelled in 2024 at putting complex robots and drones into the hands of clients across North America. These clients include others engaged in the R&D world – particularly universities and academics – as well as corporate clients and even global technology companies.

We’ve always done that. But there were two key factors that made for a difference in 2024. The first was that InDro Forge, our rapid prototyping and limited production run facility, truly came into its own. Forge, located at Ottawa’s Bayview Yards, is now our go-to for custom metal work, 3D printing and platform enclosures. (On the 3D printing front, we can fabricate objects up to one cubic metre.) The fit and finish of the products emerging from InDro Forge, whether for us or other clients, is exceptional.

The other big news from 2024 is about InDro’s growth and trajectory. We continued to expand our engineering team at Area X.O – and now have multiple high-level specialists in every sector of engineering: Mechanical, electrical, mechatronics, front-end software developers – the list goes on. So InDro scaled significantly in 2024 and has plans to continue in 2025.

We also developed new products in 2024 we’re confident will be commercially successful. As a result, there’s a shift coming in 2025. Yes, we’ll continue to do all the great R&D and custom robotics we’ve built our reputation on. But we’ll also be in a position, in conjunction with InDro Forge, to become a fully-fledged manufacturer.

Yes, we’ve manufactured before – sometimes designing and building multiple robots for a single client, or building our ever-popular InDro Commander. But we haven’t really manufactured at scale. This year, we’re confident we have the products, the capacity, the team and the vision for this to take place.

With all that context out of the way, let’s take a look at what we accomplished in 2024, starting with InDro Cortex – one of the products that has already generated significant interest and which we will manufacture in 2025.

Below: Rosie the dual manipulator robot – one of many complex builds for clients we carried out in 2024

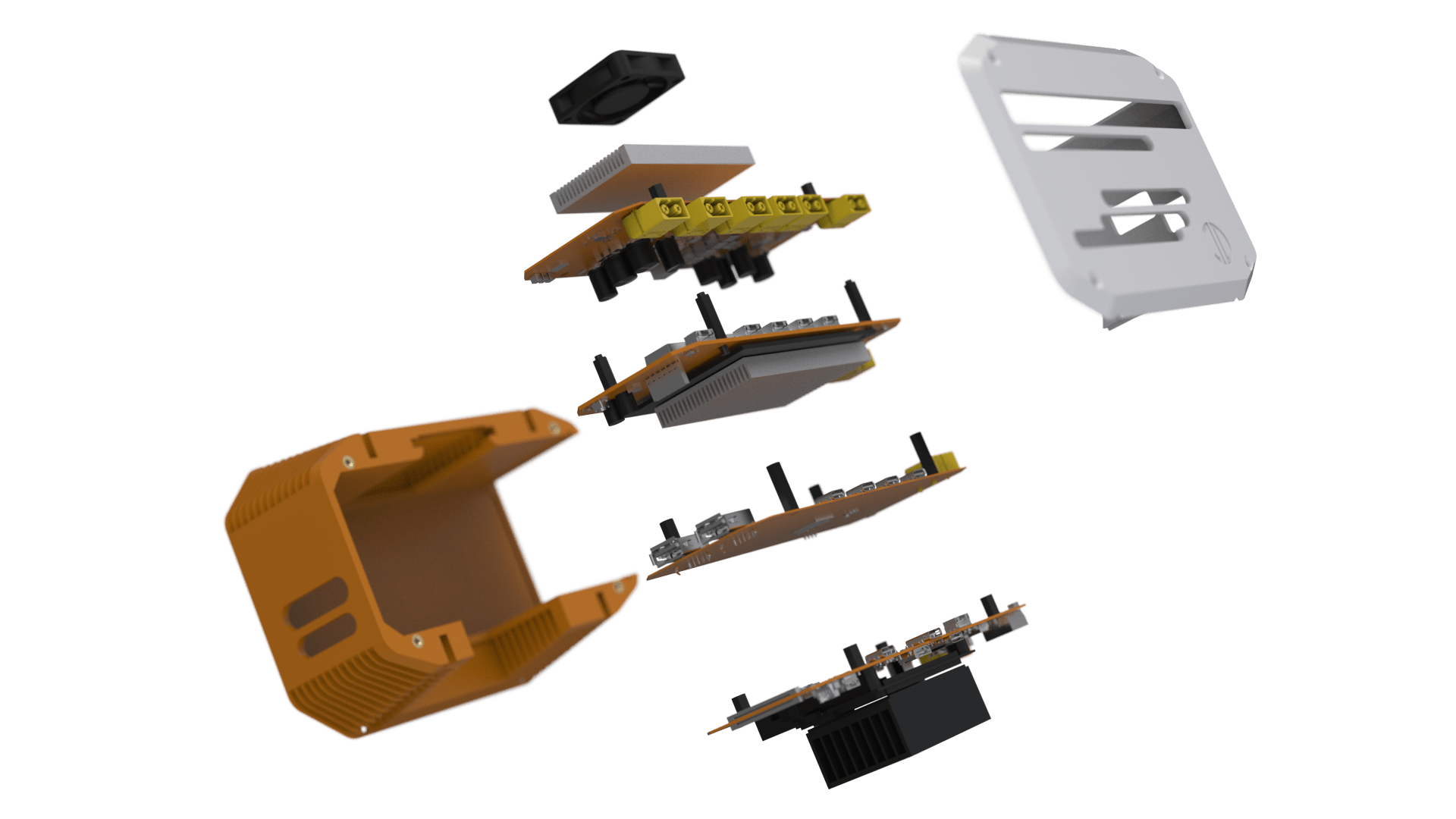

INDRO CORTEX

InDro Cortex is a very small, very smart box that will elevate the capabilities of any robot or drone. It’s also the logical successor to our popular InDro Commander. That product also made robots smarter – and far easier for anyone with even modest robotics knowledge to integrate.

Commander contains high-power AI compute. Cortex takes that up a significant notch. Its brains reside within the NVIDIA Jetson AGX Orin Developer Kit, rated at 275 TOPS – that’s 275 Trillion Operations Per Second. Both the 8GB and 16GB versions will be integrated into Cortex, pending client needs.

In addition, Cortex contains a high-speed 5G/4G modem and antenna for remote teleoperation, GPS, the ROS1 and ROS2 (Robot Operating System) software libraries, along with multiple USB slots for rapid sensor integration and power supply. Someone purchasing a robotic locomotion platform could simply add Commander or Cortex – and then rapidly integrate multiple sensors. Those sensors are automatically detected, so it truly is a “plug & play” device. Pretty much every custom robot we build for clients has one of these boxes, and many clients purchase Commander as a standalone in order to simplify and speed their own integrations.

Because our motto is “Invent, Enhance, Deploy” we couldn’t stand on our laurels. As newer AI compute and other components came along, we knew it was time to improve an already-good solution.

“InDro Cortex grew out of the idea of making a general purpose backpack/module that any OEM could put on their motorized product – everything from a ground robot to even a golf cart, drone, car, truck or RC platform,” says Engineering Lead Arron Griffiths. “That single module makes any platform ROS-enabled, AI-ready and 5G connected.”

And it’s small. We designed four circuit boards to ensure smooth integration, top-speed remote teleoperation and even secure WiFi.

“It’s tiny so it fits on everything – whether that’s a ground robot or a drone,” says InDro Vice President Peter King. “So basically we can turn any platform into a very powerful robot without all the time and hassle.”

There’s been incredible interest in Cortex already. We plan on manufacturing and shipping to clients in Q3. Pre-orders are being taken now by Head of R&D Sales Luke Corbeth.

Below: An exploded view of InDro Cortex – the brains for your next robot, followed by our V1 enclosure

INDRO CONTROLLER

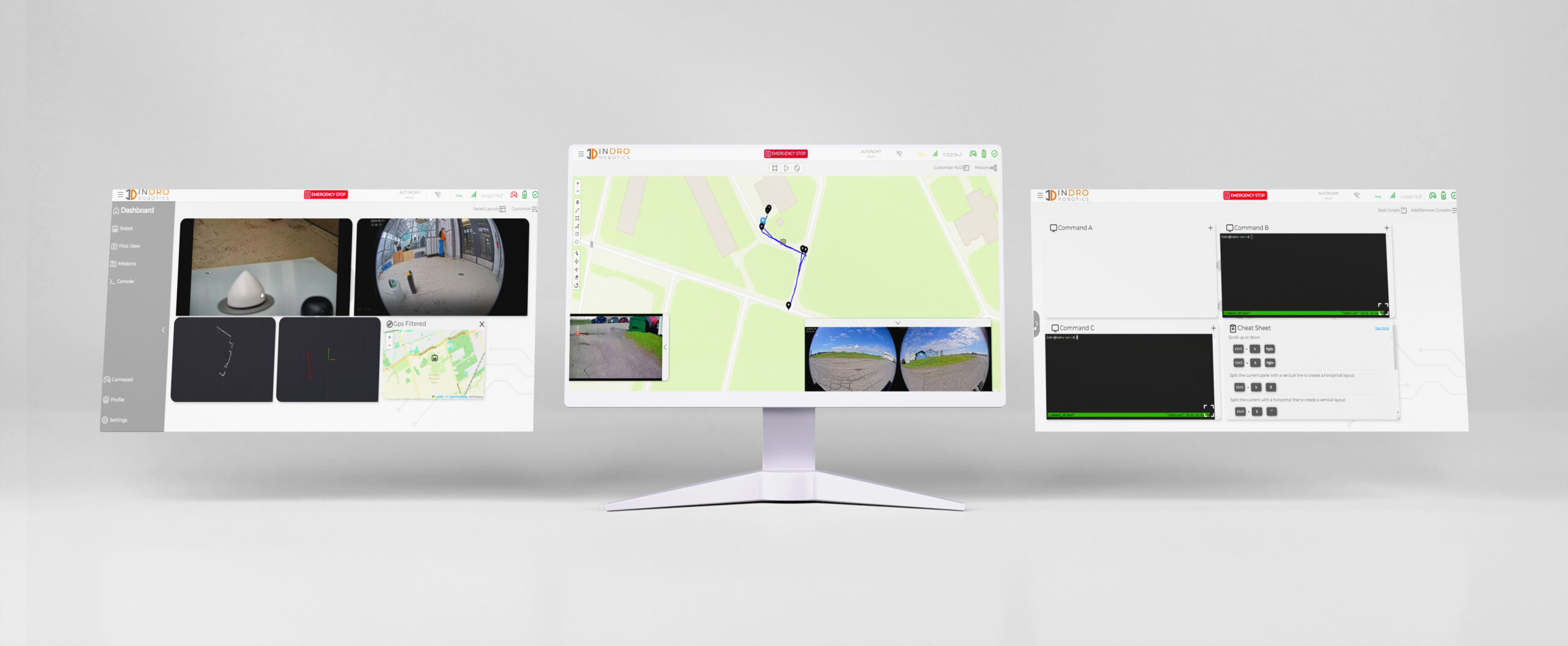

Another highlight of 2024 was on the software side. Our clients were asking for an intuitive and secure mission planner/controller, something that would make it easy to plan even highly complex autonomous missions.

InDro Controller is a powerful desktop UI for operating any robot. With a highly secure data connection, InDro Controller automatically senses all key parameters of any robotic device. It detects any sensors, providing a data feed from all of them with minimal latency. It also checks out overall robot health and provides instant feedback for the operator.

“It can handle all sorts of data,” says Lead Software Engineer RJ Bundy. “It doesn’t matter if the robot has standard or custom sensors, InDro Controller can automatically detect and visualize them. For example, if you added a radar unit to an existing robot, the system will pick up on that immediately.”

We’re not simply talking about missions that go from waypoint to waypoint. InDro Controller will remember any specific actions carried out during a mission and save and repeat them. For example, imagine you have a pressure gauge on site that needs to be monitored. The first time that mission is planned, the operator would position the pan-tilt-zoom camera on that asset and capture the image. The next time your robot goes out? InDro Controller will recall all parameters and position the camera, zoom and shoot autonomously. The system can even be programmed to fire an alert if a parameter on that gauge is being exceeded (or if a component exceeds thermal limits, etc.).

A basic version of InDro Controller ships with every robot we produce for clients. The Enterprise version can be leased at an affordable price, with continuous upgrades down the road at no additional cost.

Oh. We also made incredible strides with our InDro Autonomy software stack. With this on board, you can carry out Simultaneous Localization and Mapping (SLAM) missions in completely unfamiliar environments. Even GPS-denied locations can be navigated with ease.

Below: A look at InDro Controller – which pairs perfectly with InDro Cortex-enabled robots but is itself robot-agnostic

OTHER MILESTONES AND HIGHLIGHTS

Truth is, were we to spend even a couple of paragraphs on each of the many things accomplished in 2024, you’d be reading an opus that would take you well into 2025. We know your time is as valuable as ours, so we’ll touch on the highlights as briefly as possible, with links to complete posts if you’d like more information.

Let’s start with clients. These are some of the many robots we built and shipped in 2024. Some of them were one-off creations, while some orders were for multiple robots.

- Rosie the Robot: A dual-arm manipulator robot built for the Intelligent-Cyber Physical System Lab, or I-CPS, at Polytechnique Montréal

- Four swarm robots for North Carolina State University’s Department of Mechanical and Aerospace Engineering

- The Street Smart Robot, built to autonomously detect and report anomalies on bicycle paths during winter to help keep cyclists safe

- A total of 28 robots or platforms for Polytechnique Montréal‘s MIST Lab (Making Innovative Space Technology). Their team, using our platforms, was even featured on CNN

- Multiple custom inspection robot builds for a major US client we cannot name at this time

- The new Sentinel inspection robot for remote teleoperation in even the harshest of environments

There were more, but these hit the high points in terms of robots out the door that we can reveal without violating NDAs.

We also put in a lot of time with our partners at Cypher Robotics. Cypher is a separate company, but InDro is the technology incubator, assisting Cypher with challenging builds and testing. We are very proud of our work in helping to bring its cycle-counting/precision scanning Captis solution from plans to reality. This autonomous robot has been tested in massive Canadian warehouses, and picked up a ton of buzz at the MODEX and AUTOMATE conferences. Cypher Robotics was even invited to New Zealand, and has partnered with that country’s leading telco provider Spark.

Similar to our technology partnership with Cypher Robotics, InDro has also been assisting the great team at Real Life Robotics – a startup making great inroads in last-mile delivery services. Real Life’s engineering team drew up plans for its newest version of delivery robot “Bubbs” – and InDro Robotics and InDro Forge executed those plans. The result? An autonomous delivery robot that’s been making the rounds (and receiving a lot of coverage) delivering food for animals at the Toronto Zoo.

BUSY BUSY BUSY

While most eyes seem to be on our work at Area X.O (where we invent, design and build robots), InDro is always busy on multiple fronts. We are constantly involved in research for such bodies as the National Research Council, the Ontario Vehicle Innovation Centre, and more. One of the many interesting projects we began in 2024 (and which continues in 2025), is carrying out precision agriculture missions at cherry and peach orchards in British Columbia. It’s a collaboration between InDro Robotics and the City of Kelowna (enabled with funding from Agriculture and Agri-Food Canada’s Agriculture Clean Technology Program).

Yes, we’re using a drone to capture multi spectral data. But – in what we believe is a Canadian first – we’re also deploying ground robots to capture additional plant health data. The missions and analysis are being carried out by our Chief of Flight Operations Dr. Eric Saczuk (who holds a PhD in remote sensing and runs BCIT’s RPAS Hub).

“This is a way of doing ground-based validation of what we’re seeing from the air,” says Dr. Saczuk.

And that’s just one of many interesting projects we were (and are) involved in. These include:

- Joining a consortium selected to take part in Phase 2 RPAS Traffic Management trials for Transport Canada

- Attending GITEX and high-level meetings with some of the largest companies in Dubai as part of a trade mission

- Carrying out complex missions and offering technical expertise to startup SkyScout AI

- Entering the marine robotics sector

And yes, there’s more.

Our own Kate Klassen, Canada’s most well-known drone instructor (she’s also a multi-engine rated flight instructor with traditional aircraft) continued her exceptional training and advocacy work. She carried out seminars (including a recency session at the Aerial Evolution Association of Canada’s annual conference in Ottawa), took part in highly complex RPAS missions, and even expanded offerings on her already-comprehensive online drone instruction portal, FLYY.

The newly launched Compass Series of courses is geared to help those who are recently certified to “find direction” or “get their bearings” (we see what you did there, Kate). Based on interviews across her network of experts, you can now learn the fundamentals of what it means to use drones in forestry, C-UAS, LiDAR, AAM and photogrammetry – with more to come!

Klassen (and InDro) are looking forward to new Transport Canada regulations that will enable non-complex BVLOS missions in 2025 without the need for a Special Flight Operations Certificate (SFOC). InDro, if you’re not aware, was the first company to obtain a blanket BVLOS SFOC from Transport Canada, and was the first company to obtain a drone cargo license from the Canadian Transportation Agency. So drones are a deep part of InDro’s DNA.

But so is fun. And to that end, we partnered with the immensely popular Hacksmith YouTube channel – providing a pair of robotic arms that were, well, integrated onto a human. You can catch all the laughs (and challenges) in the video below. Part II is coming this year!

INDRO’S TAKE

We have to say it’s pretty satisfying to reflect on the year that was. Team InDro has gone above and beyond once again, hitting multiple significant milestones for ourselves and our clients. What’s more, we had fun doing it.

“I’m immensely proud of all the hard work carried out by our team,” says InDro Robotics CEO and Founder Philip Reece.

“And while it’s an impressive list of accomplishments, the big story is really about growth. InDro has scaled significantly and is now poised to start expanding with manufacturing in 2025. There’s already significant demand for Cortex, and we look forward to seeing that box come off production lines later this year.”

And a quick personal note from the author. I always enjoy interviewing our engineers and learning more about our latest projects. But I also like to focus on InDro’s people from time to time. Two of the stories I really enjoyed this year are these profiles of two team members who made their way from India to InDro…and this look at Head of Engineering Arron Griffiths. Oh – and let’s not forget about Artist-in-Residence Stephan Tzolov.

We look forward to 2025, which – in more ways than one – promises to be an exciting New Year.