How Stereolabs ZED X Cameras Helped InDro Robotics Revolutionize Autonomous Navigation

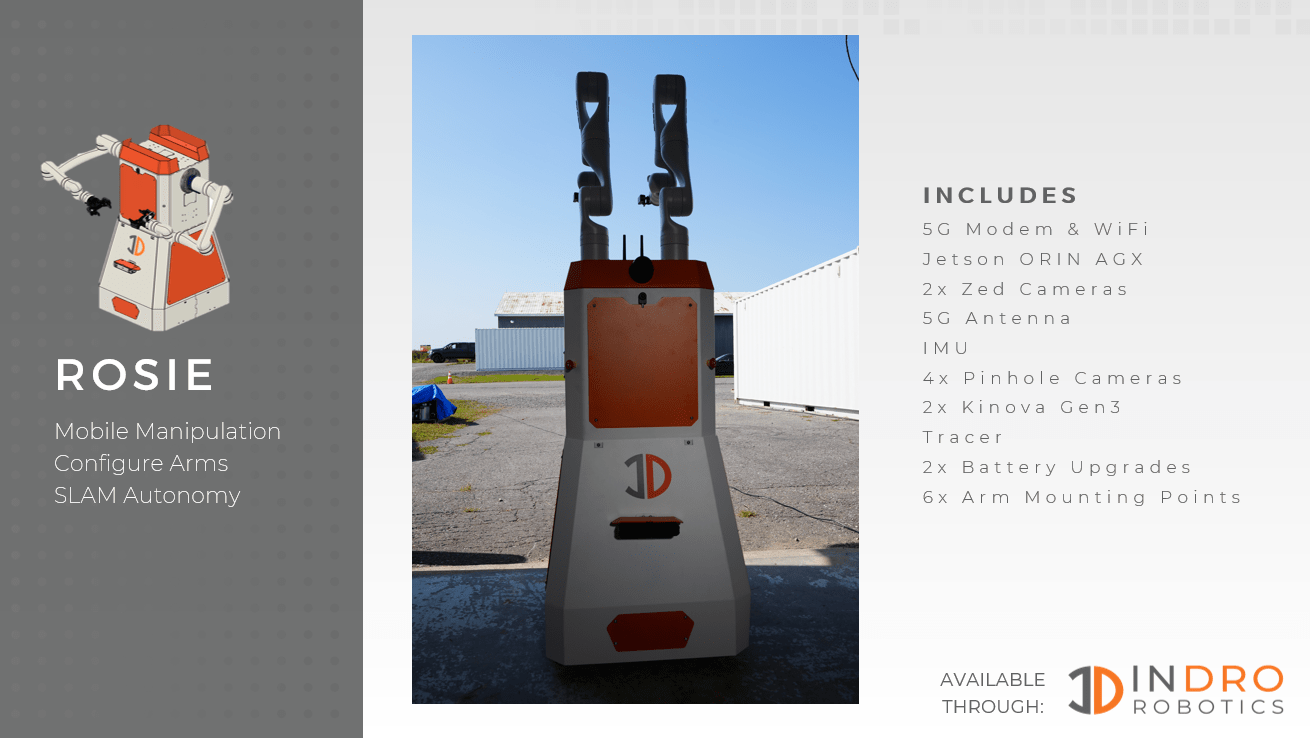

At InDro Robotics, we specialize in cutting-edge autonomous systems, including our flagship Sentinel inspection robot. We needed a vision-based perception system that could deliver high-performance 3D mapping (SLAM) consistently across diverse and challenging environments—from indoor facilities to high-speed outdoor operations—all while maintaining an efficient budget.

We found our solution in the Stereolabs ZED X camera system. After four years of leveraging Stereolabs technology, the ZED X has become a core component of our advanced autonomous fleet.

The Impact on Our Robotics

The integration of the ZED X directly addressed our core engineering challenges and delivered significant, measurable benefits:

- Exceptional Performance-to-Cost: The ZED X offers the ideal balance of powerful visual SLAM capabilities and cost-efficiency, allowing us to deploy advanced technology without compromising our budget.

- Enhanced Outdoor Capabilities: The integrated polarized lens was essential for our outdoor Sentinel Security Robot, drastically improving visual clarity and reliability in complex lighting conditions.

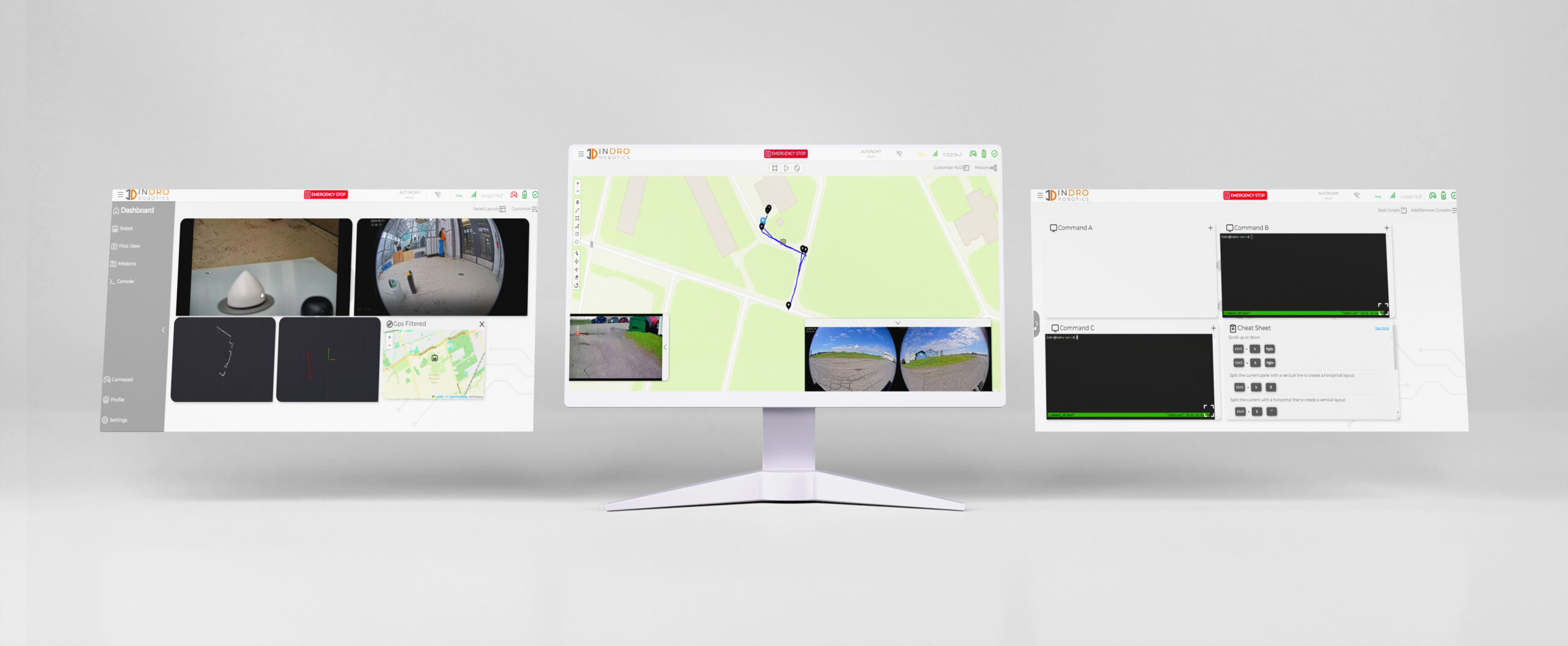

- Faster Deployment Times: Measurable improvements in mapping speed and accuracy directly lead to reduced deployment times for new robotic systems, accelerating our project turnaround.

- Accelerated Development Cycles: Robust ROS 2 SDK support and simplified integration enabled our engineering team to focus on innovation and advanced autonomous behaviors, rather than vision system troubleshooting.

As our Director of Engineering, Arron Griffiths, notes, the ZED X represents “a significant leap forward in performance and integration,” proving the value of strategic technology partnerships in driving innovation.

Read the full story HERE to learn how our partnership with Stereolabs enhanced the functionality and reliability of our autonomous robot fleet.