2022 InDro Highlights

Wow. Another year has passed.

And for InDro Robotics, it was a year marked by new products, new deployments, and multiple milestones.

We did a deep dive on the year with our Year in Review story, which you can find here. But we realise some people might prefer a condensed version. So here we go, starting with the image above.

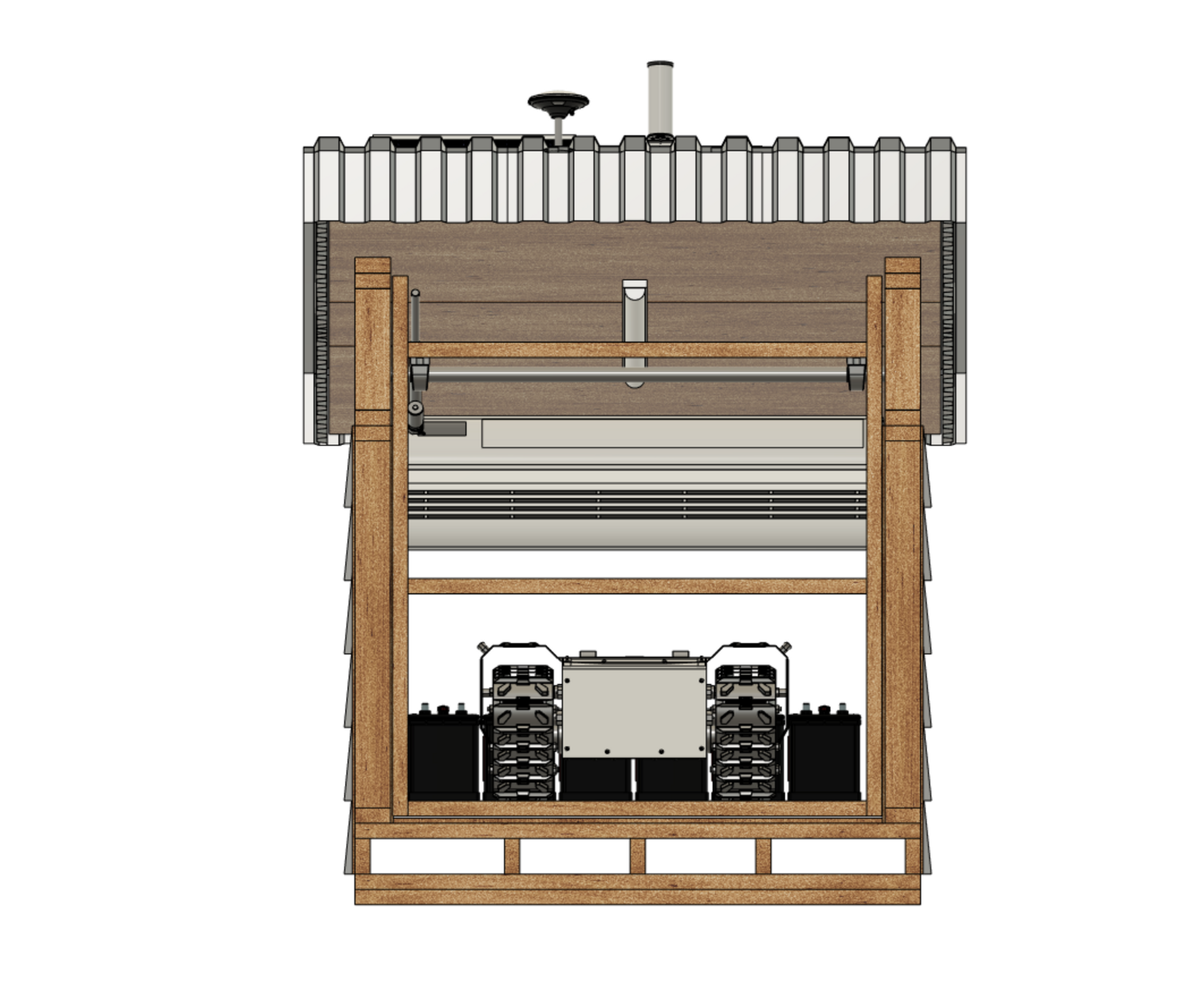

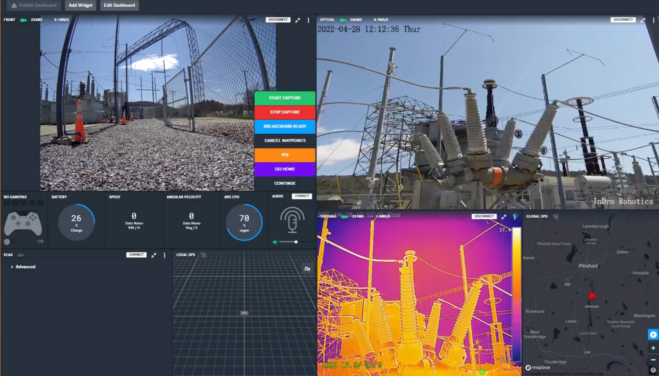

That’s Sentinel, our rugged teleoperated robot for remote inspections. We launched that product at the very beginning of 2022. It’s been designed for remote inspections, carried out over 4G and 5G networks. We customise Sentinel’s sensors based on client needs, but the standard model comes with a 30x optical Pan-Tilt-Zoom camera, thermal sensor, and a high-res wide-angle camera that gives the operator a clear view of surroundings.

Operations are a snap, using an Xbox controller plugged into a laptop with a comprehensive dashboard. Even dense data can be streamed and downloaded in real-time over 5G. In fact, we’ve proven Sentinel’s minimal-latency capabilities from more than 4,000 kilometres away. (That took place from Bellevue, Washington State, where we were invited to demo our system by T-Mobile.)

It didn’t take long for word to get around. A couple of months after Sentinel’s launch, we were invited to put it through its paces at the Electric Power Research Institute, or EPRI. Check out this next image – it’s a frame grab from the Sentinel dashboard, and was captured during a mission at an EPRI testbed electrical substation in Lenox, Massachussetts.

There’s a lot we could tell you about Sentinel but we’re trying to keep this tight. If you’d like more in-depth details you can read this story, or reach out to superstar Account Executive Luke Corbeth here.

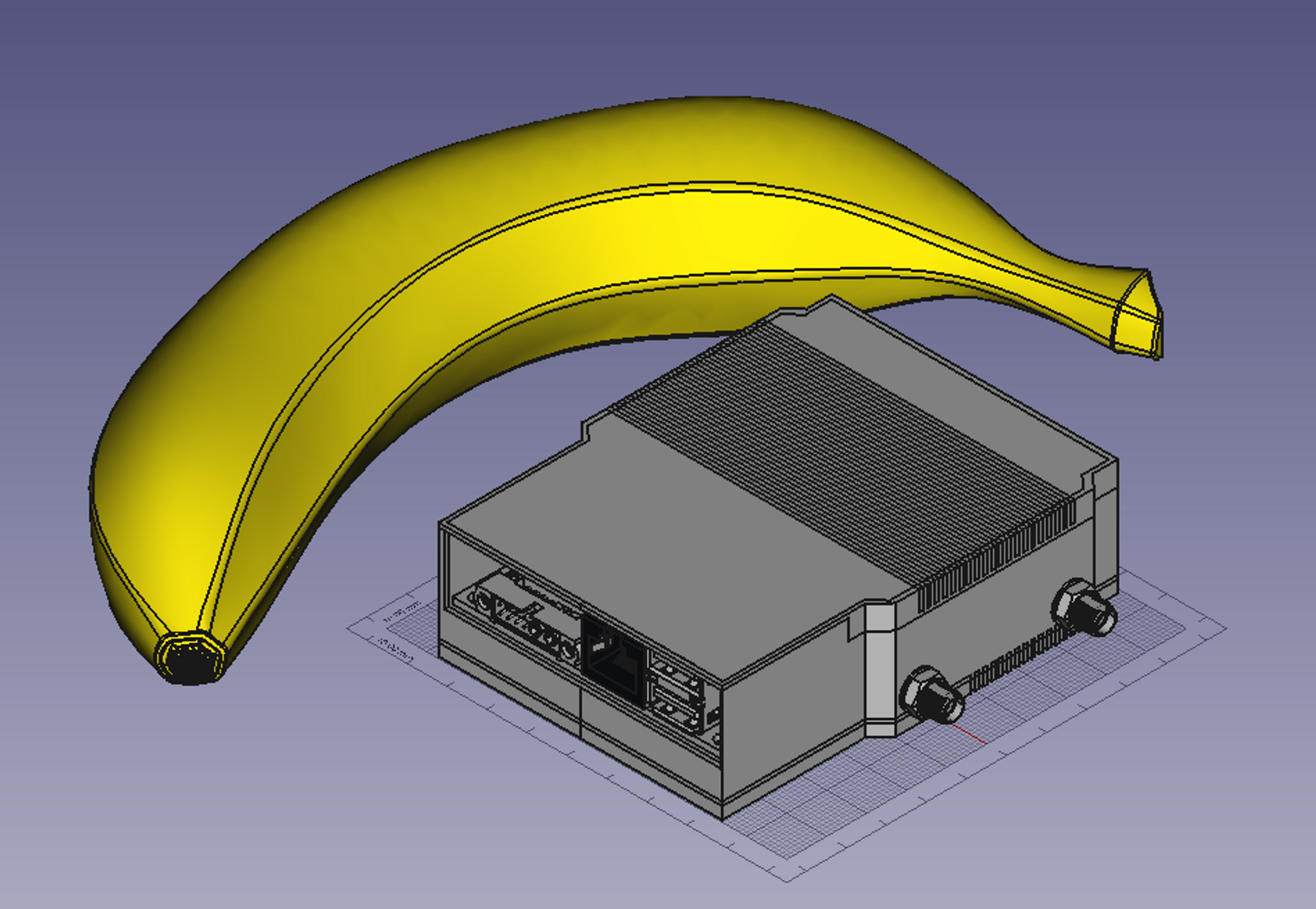

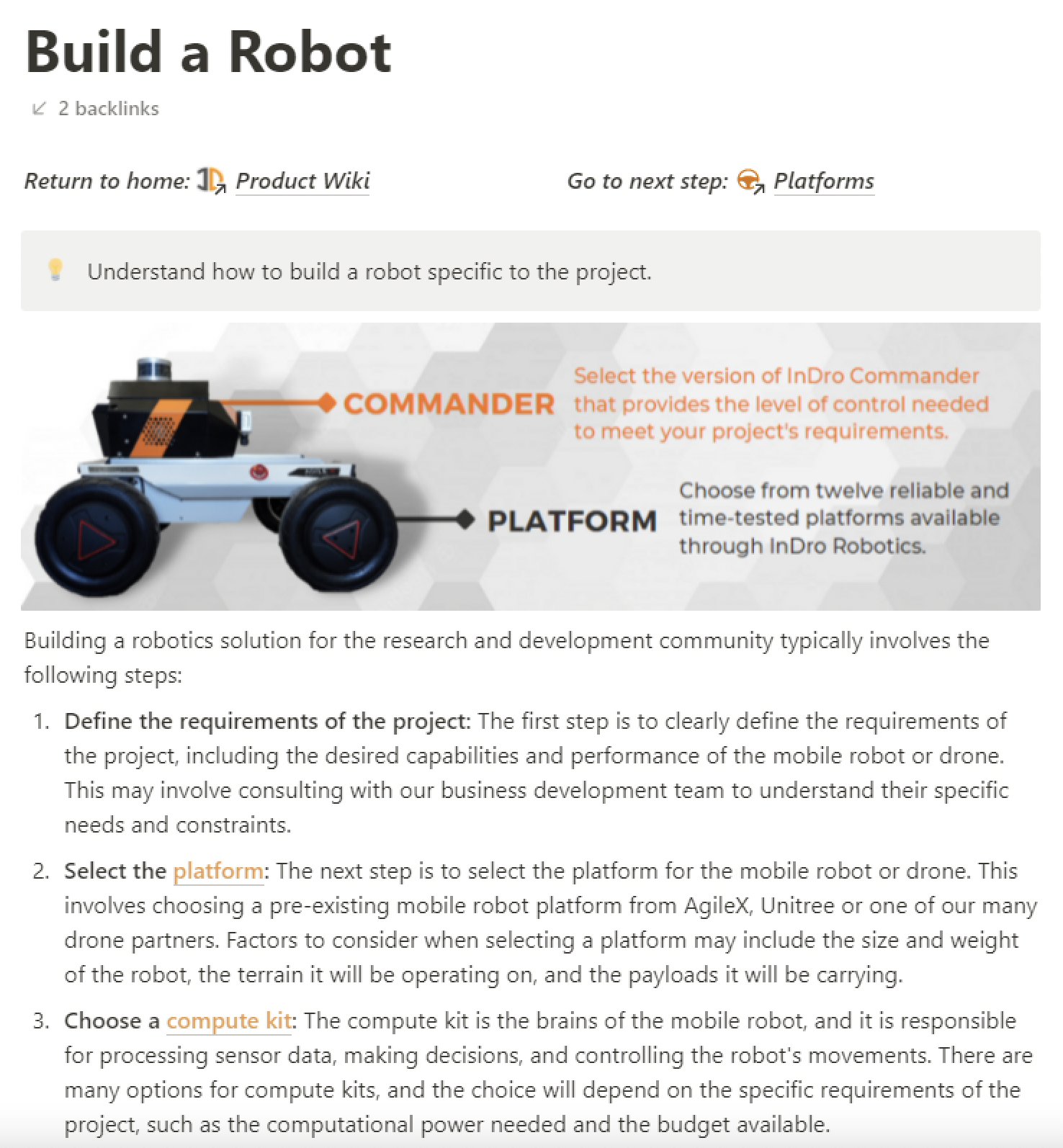

INDRO COMMANDER

A significant part of what gives Sentinel its various superpowers is an innovation we call InDro Commander. It’s a bolt-on box that contains a camera, EDGE computer, a 4G- and 5G-compatible modem and the ROS1 and ROS2 software libraries. That means it’s a snap for clients to add any additional sensors they’d like without the hassle of coding.

You can operate any InDro Commander-enabled platform using an Xbox controller over a highly intuitive dashboard on your desktop or laptop. FYI, that box you see just above the InDro Logo (and just below the camera) in the image below? That’s InDro Commander.

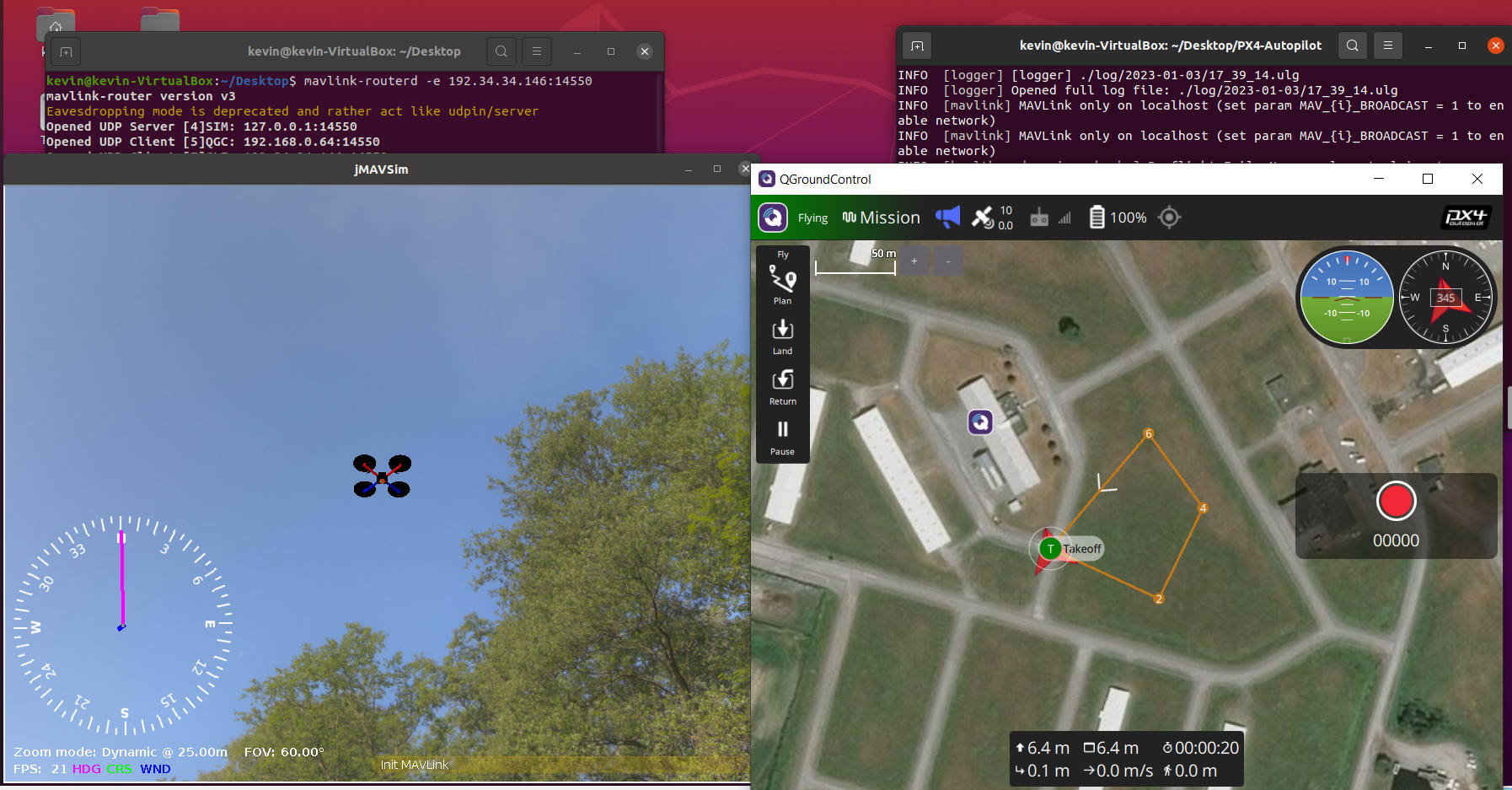

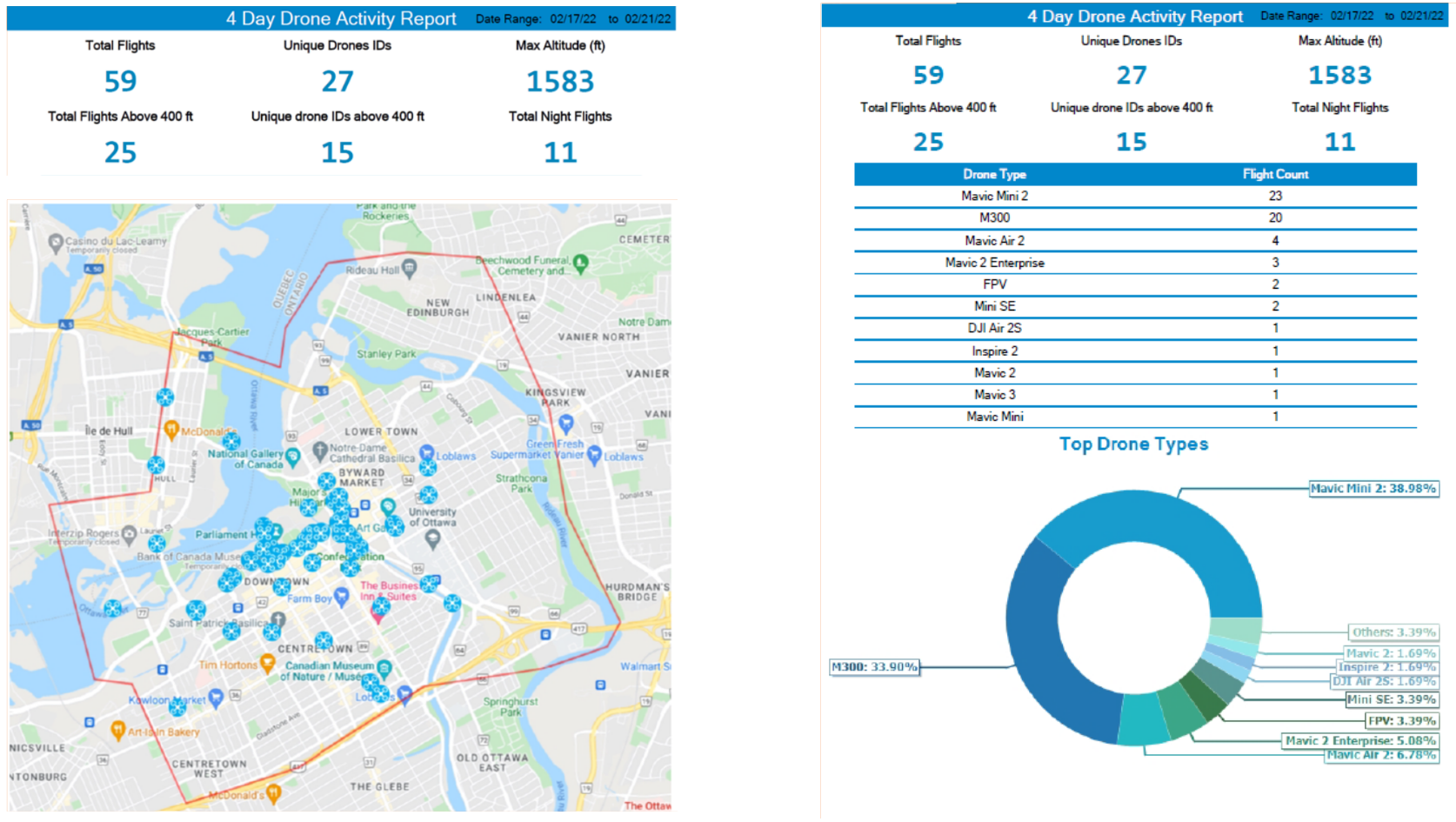

DRONES

Though InDro has a stellar reputation for ground robotics, the company was founded on the Unmanned Aerial System side of things. So we’ve been busy in that arena, as well.

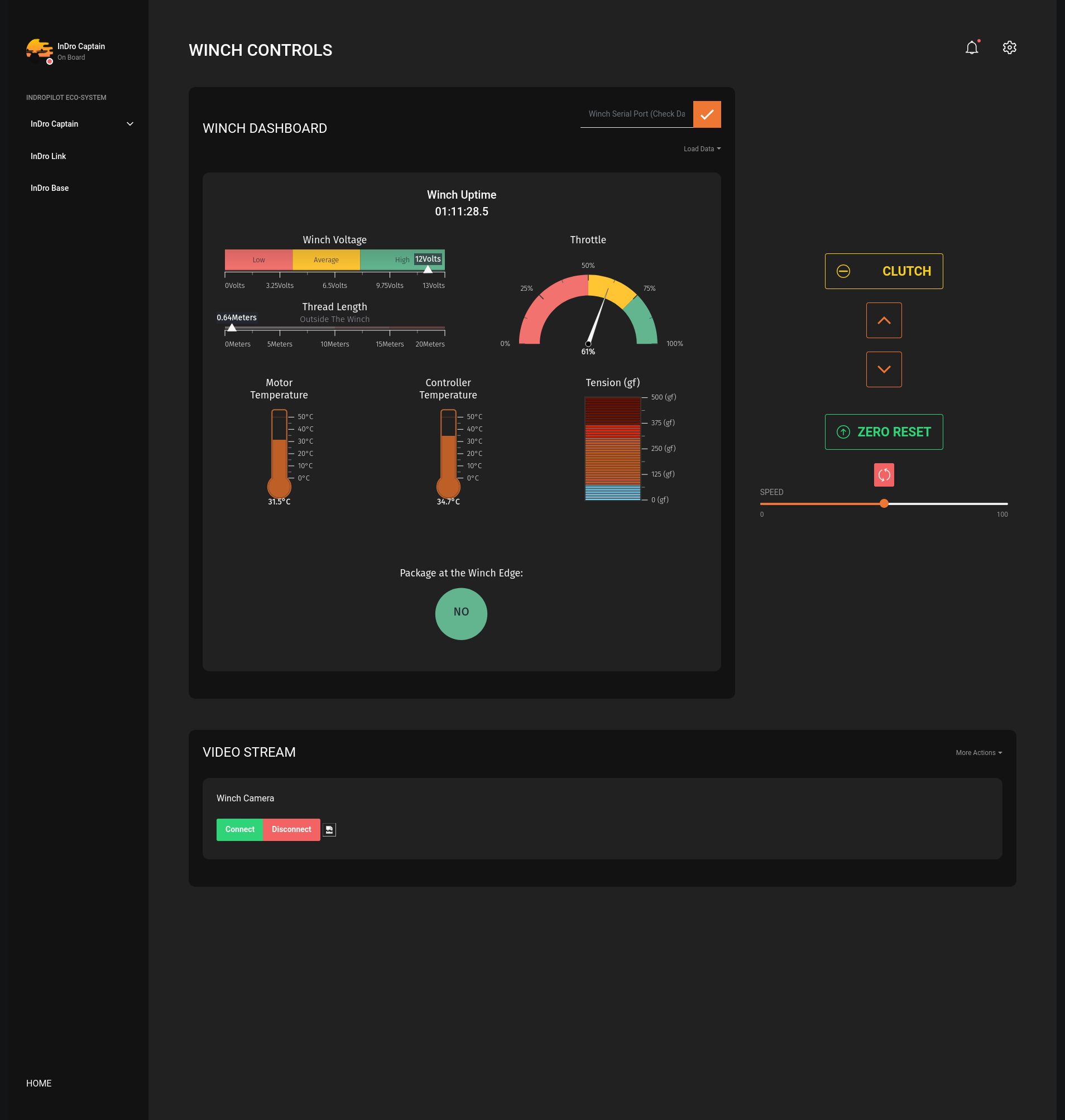

The most significant development of the year is a software and hardware package we call InDro Pilot. In a nutshell, it’s a bolt-on module that’s similar to Commander. It enables remote BVLOS operations over 4G or 5G, dense data throughput, simplified sensor integration – plus the ability to broadcast to nearby traditional crewed aircraft that drone operations are taking place in the vicinity.

That hexagonal box in the image is Version 1.0 of the hardware side. We’ve since created a much smaller and lighter version, capable of transforming any Enterprise drone using the Pixhawk flight controller into a low-latency, BVLOS super-RPAS.

GROUND (BREAKING) DELIVERIES

In 2022, InDro teamed up with London Drugs to test out ground deliveries via our ROLL-E robot.

There were two separate trials. The first, in Victoria, involved ROLL-E taking goods ordered online to a parking lot for touchless, curbside delivery. The second, in Surrey BC, involved the second generation of ROLL-E delivering goods from a London Drugs outlet to a consumer’s home. ROLL-E features 4G and 5G teleoperation, and is equipped with a total of six cameras (including two depth-perception cameras), giving the operator tremendous spatial awareness.

That’s ROLL-E 2.0, in the image below. Its secure cargo bay – which unlocks when the robot reaches its destination – can carry up to 50 kilograms.

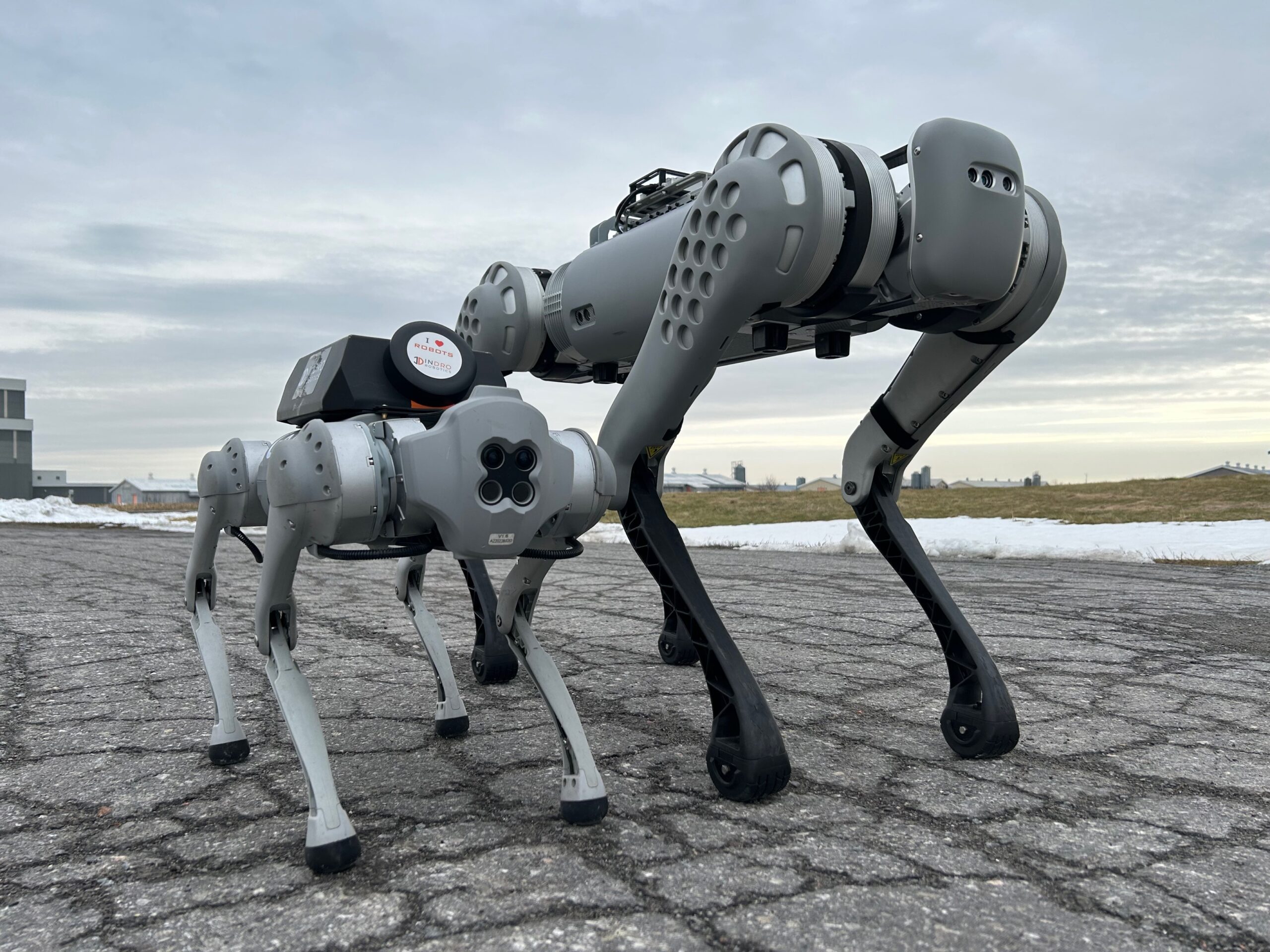

GOOD DOG

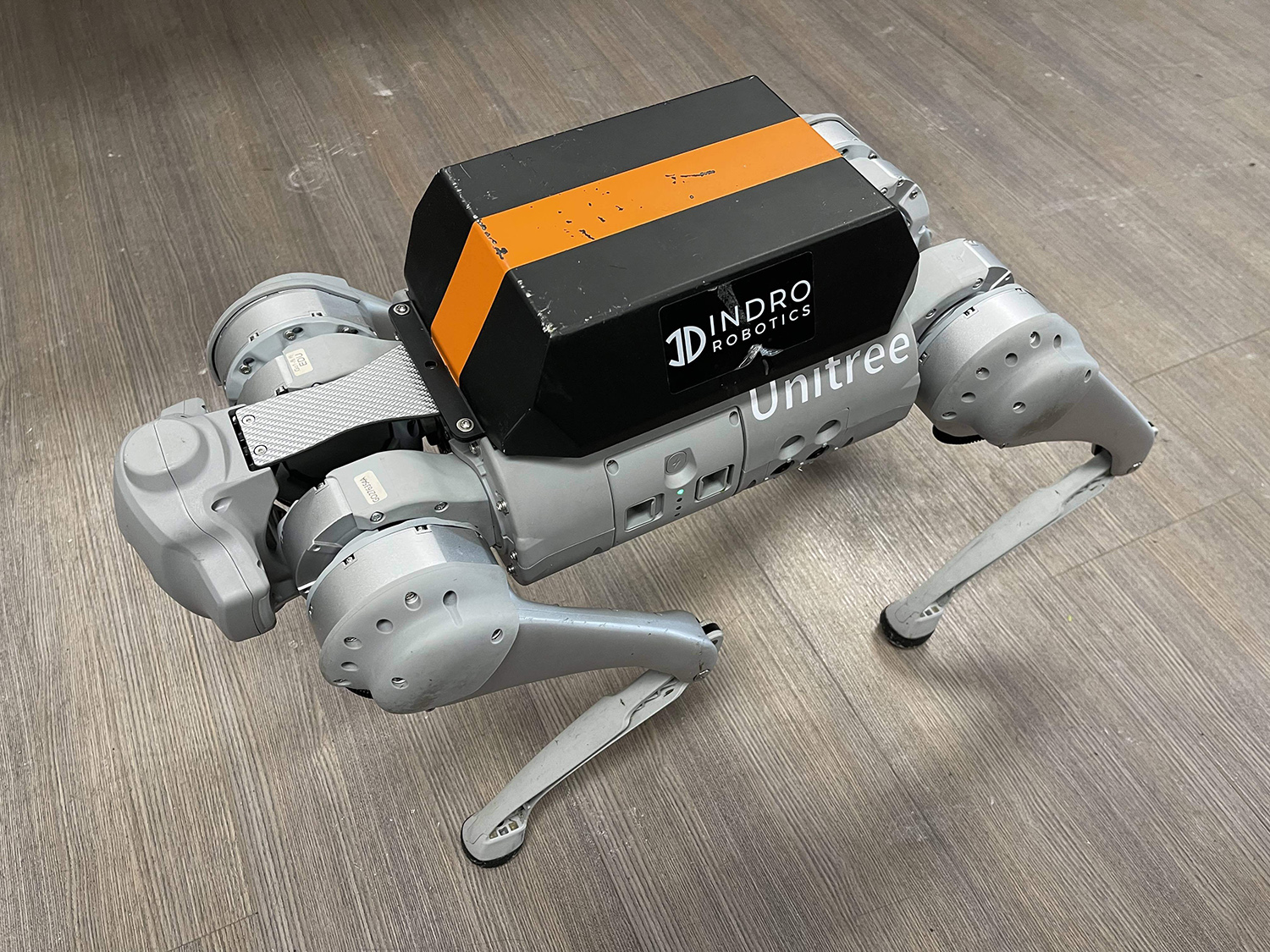

Also in 2022, InDro Robotics became a North American distributor for the Unitree line of quadruped robots. These rugged, agile robots are well-suited to a variety of tasks, including remote inspection. In the video below, Luke Corbeth puts the entry-level GO 1 through its paces.

InDro backpack

Remember InDro Commander, the box that enables remote teleoperations and easy sensor integration? We figured a module like that could really expand the capabilities of the Unitree quadrupeds.

And so – you guessed it – we built it. We call this device InDro Backpack, and you can see it on the robot below.

meet limo

InDro Robotics is also a North American distributor of the excellent AgileX robot line. This past year saw the introduction of a very cool machine for education and R&D called LIMO. It comes with an impressive number of features straight out of the box, including:

- An NVIDIA Jetson Nano, capable of remote teleoperation over 4G

- An EAI X2L LiDAR unit

- Stereo camera

- Four steering modes (tracked, Ackerman, four-wheel differential, and omni-directional)

It’s a powerful, SLAM-capable machine. Best of all? It’s really affordable.

montreal marathon

Three InDro employees took part in the Montreal Marathon – but they were largely standing still.

In fact, they were operating sub-250 gram drones as part of a medical research pilot project. The drones – two were constantly in the air throughout the run – were positioned at a point near the end of the course where runners sometimes encounter medical distress. Live feeds from the drones were monitored in a tent by researchers for two reasons: To see if the aerial view could help them quickly identify someone needing help, and to help pinpoint their location so assistance could be rapidly dispatched.

The results? The drone feeds helped quickly identify and locate two runners in need of help.

“The view from above when monitoring moving crowds is just incomparable,” says Dr. Valérie Homier, an Emergency Physician at McGill University Health Centre and the lead researcher on the project.

Below: InDro pilots Kaiwen Xu, Ella Hayashi and Liam Dwyer.

TCXpo

One of the highlights of the year was the TCXpo event at Area X.O in Ottawa. Sponsored by Transport Canada and Innovation, Science and Economic Development Canada, it was a full day of demonstrations from Canadian leaders in the world of Smart Mobility.

InDro was there, of course, displaying our InDro Pilot-enabled Wayfinder drone, as well a *lot* of ground robots. CEO Philip Reece moderated a panel – and was also in charge of airspace for multiple drone demonstrations. That’s Philip, below, talking about aerial and ground robotics to attendees.

training

Speaking of drones, we also launched drone training and resource portal FLYY. Online lessons are carried out by our own Kate Klassen, widely recognised as one of the best (and most qualified) drone instructors in North America. Whether you’re looking to obtain your Basic or Advanced RPAS certificate, or want to further expand your skills, Kate’s got the goods.

If you’re looking for training for multiple people, Kate offers discounts for companies and educational institutes. You can reach her here.

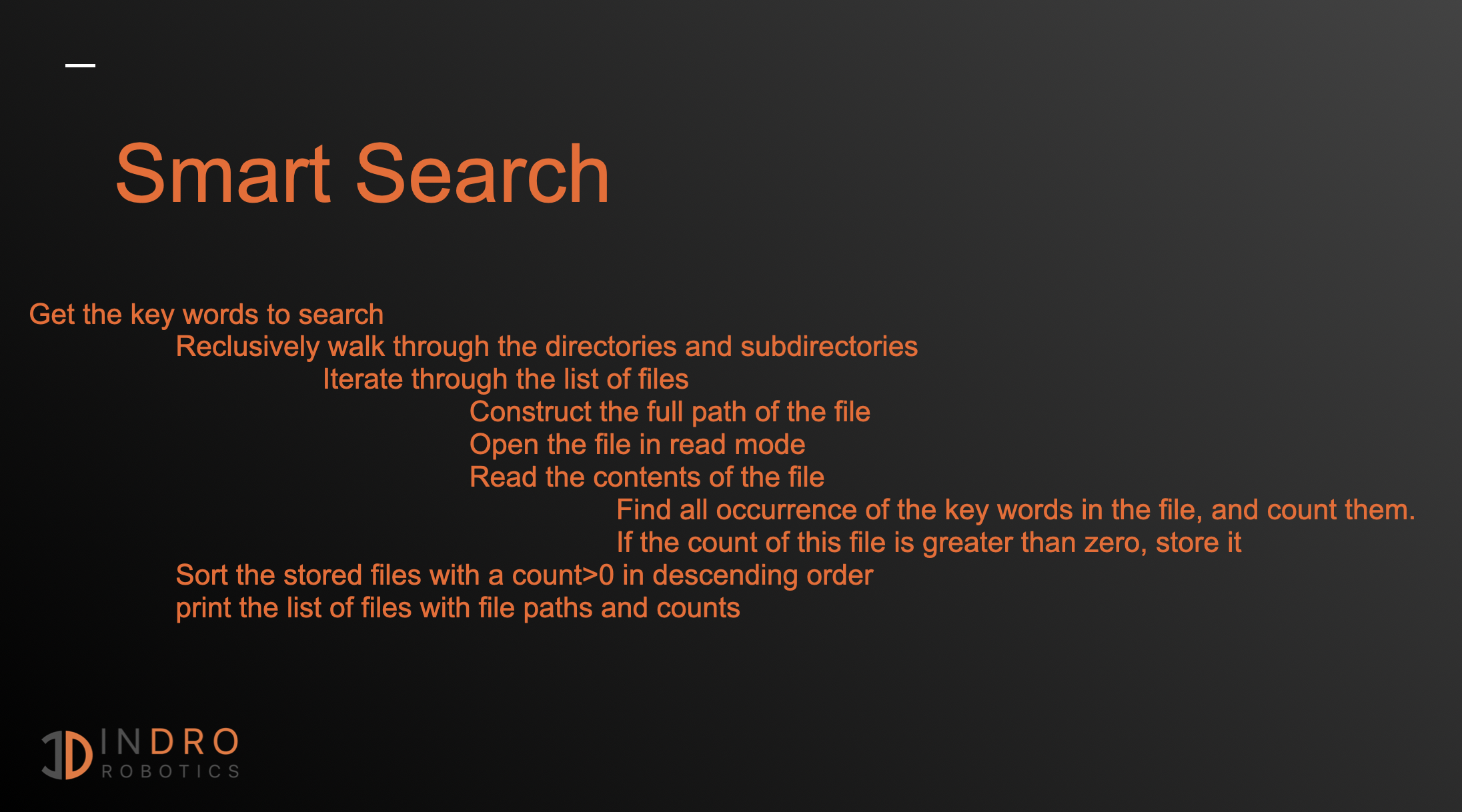

it's a secret...

The other big thing happening in 2022 (and continuing in 2023) was InDro’s work with major global clients. We can’t disclose that work due to non-disclosure agreements, but we can tell you we’re busy with multiple, exciting, ongoing projects!

Finally, we closed out 2022 with another successful InDro Hack-a-Thon. Employees were given a day and a half to work on a project or process that could benefit InDro down the road. Once again, Team InDro delivered, with some amazing projects completed within the deadline. You can read all about it here.

a final word...

As you can see, it’s been quite a year – and CEO Philip Reece couldn’t be happier.

“I’m incredibly proud of the work InDro accomplished in 2022,” he says. “Our engineering and sales staff consistently punch above their weight, with multiple significant milestones – including excellent revenue growth – achieved in the past year. Just as gratifying is the fact our employees love what they do.”

Very true. Now stay tuned for an even more amazing 2023.

And if you’d like to reach InDro, just give that little orange button a click. Though we’ve got plenty of robots, we’ll make sure a real human being gets back to you shortly.