By Scott Simmie

Some companies – and we’ve built for them – have plunged head-first into the adoption of industrial inspection robots. They’re perfect for routinely inspecting assets like electrical substations, refineries, construction sites – the list goes on (and on). InDro robots are currently hard at work on multiple sites – and in more than one country.

Yet still, some potential clients hesitate.

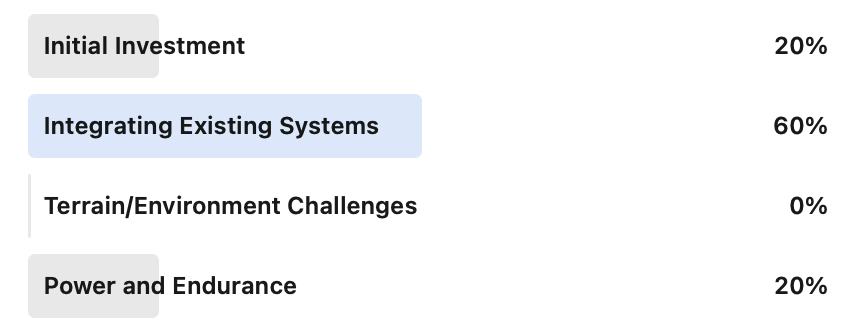

So we thought we’d take the pulse with a survey. Here’s the question we asked, via LinkedIn: “Which of the following challenges do you think is the biggest barrier preventing companies from adopting industrial inspection robots?” Here were the choices:

- Initial investment

- Integrating existing systems

- Terrain/environment challenges

- Power and endurance

And here…are the results:

PERCEPTIONS…AND SOLUTIONS

So let’s tackle those concerns.

Initial investment is holding back 20 per cent of respondents from taking the plunge. Fair enough. Robots aren’t cheap. A fully customised solution with multiple sensors capable of regular, autonomous inspections in a demanding environment has traditionally cost $100k+ (and still can). Clients wonder if the investment will result in a positive ROI.

“With any new technology tackling any new use-case, it can be challenging to build an ROI calculation right out of the gate because you can’t truly know until you get it out in the field and and are able to use it in the actual desired use-case,” says Head of R&D Sales Luke Corbeth.

But he points out that many clients, once they have purchased a robot, discover that it not only offers ROI for the intended task, but that it can handle ancillary use-cases they hadn’t even considered at the outset. That, he says, has resulted in greater return on investment than some clients initially calculated. The other factor Luke points out is that the last couple of years have seen more powerful solutions appear at lower price points.

“Even two years ago, if you wanted a system capable of multi-level inspection, you had to go with an industrial-sized robot, right? You needed something like the Unitree B2 or Boston Dynamics Spot. Those would run you six figures before you even outfit it with software, cameras, acoustic sensors etc.” says Corbeth.

INTEGRATING EXISTING SYSTEMS

This, according to our survey, was the biggest stumbling block. A full sixty per cent of respondents identified this as a barrier to adopting industrial inspection robots. In all likelihood, these are companies that have legacy systems in place that have served them well – and the perceived complexity of integrating a new robot seems daunting. As Corbeth puts it: “Change is inherently hard.”

But there are solutions – ways for newer robots to capture and integrate data into existing systems, even if they are somewhat dated. Yes, there may be friction. But it’s not the barrier some perceive. InDro’s systems are Open Source/Open Architecture, allowing in-house engineers (or our own) to easily customise the software so the data and your existing system can co-exist in harmony.

Some sectors also use what’s known as “vertical specific” software, meaning systems built for say, the Oil and Gas sector, warehouses (WMS), mining, etc. But that’s not the roadblock some may perceive, says Corbeth.

“As long as the client is willing to expose an API (Application Programming Interface) to us, it’s relatively easy to point all of the data there. So instead of that data being manually collected and uploaded, now it’s automatically captured through autonomous missions and then automatically uploaded over whatever communications infrastructure the client already has.”

Understanding existing client systems and integration concerns is a key part of our discovery process with new clients. We ensure, from the outset, that integration will be as seamless as possible.

TERRAIN, POWER, ENDURANCE

None of the respondents indicated terrain was an issue. And perhaps that’s not a surprise. The latest generation of platforms, particularly wheeled quadrupeds like the Go2-W, can glide or clamber over just about anything. Tracked platforms can handle mud and snow. There are solutions for virtually every terrain.

Power and endurance are another matter. No one wants an inspection robot that can’t finish the job. In fact, twenty per cent of those who voted in our survey identified this as a concern. And who wants the hassle of plugging something in to recharge after a mission?

The reality is that there have been gains in both power and endurance with the latest generation of platforms. What’s more, InDro can customise any robot to autonomously dock with a wireless charging station so it’s ready for the next mission with no human intervention. Says Corbeth: “It’s pretty much a non-issue at this point.”

With all that being said, there are some unrealistic expectations out there, fuelled by slick videos – particularly of humanoid robots – doing amazing things. If you think you can just buy a humanoid and it’s going to be picking tomatoes the next day while interacting with human beings, think again. Modifying humanoids to flawlessly carry out human tasks takes a lot of work. But many use-cases (particularly for non-humanoid robots) are what Corbeth describes as “low-hanging fruit” – meaning tasks that have massive value implications, are easy to integrate, and get the job done.

“That’s where the sweet spot is,” he says.

Below: Our answers to concerns about integration in a slide format.

INDRO’S TAKE

We feel this survey was a useful exercise. It identified common barriers, and gave us an opportunity to set the record straight. The perceived obstacles aren’t really obstacles at all – but engineering challenges. And that’s where InDro excels.

“InDro has built many inspection robots for clients, some of whom had the same initial concerns,” says company Founder and CEO Philip Reece. “Those robots are currently carrying out regular inspections, wirelessly recharging, and heading out to work again the next day or week. Good engineering is all about problem-solving, and we love finding solutions.”

Interested? You can contact Luke to set up a no-obligation discovery call right here.