By Scott Simmie

Most of the time, InDro staff work on company projects. Generally that means developing new products, manufacturing products for clients, testing new devices in the field and carrying out service provision. Sometimes it even means packing up very large robots for safe shipment to global clients.

But there’s one time of year when all of that is set aside. Staff are given total freedom to come up with their own concepts for products or processes that could be useful for InDro Robotics. And then they’re given a brief amount of time – a day and a half – to see what they can produce. When time is up, a company-wide videoconference is held and employees unveil their creations in five-minute pitch sessions. Votes are cast, and winners are declared.

It’s the InDro version of a “Hack-a-Thon” – though some call it a “Hack-a-Tron” in homage to the movie Tron.

We set aside time for this just before Christmas, and for a couple of reasons. The first is that, as with most companies, things slow down a bit during the holiday season. The second reason is – like the holidays – this event is worth celebrating.

Before we hop into a brief summary of the presentations, here’s a quick look at the kinds of projects employees were encouraged to pursue:

Rules

Yes, there are rules – including no “Death by Powerpoint.”

On with the show!

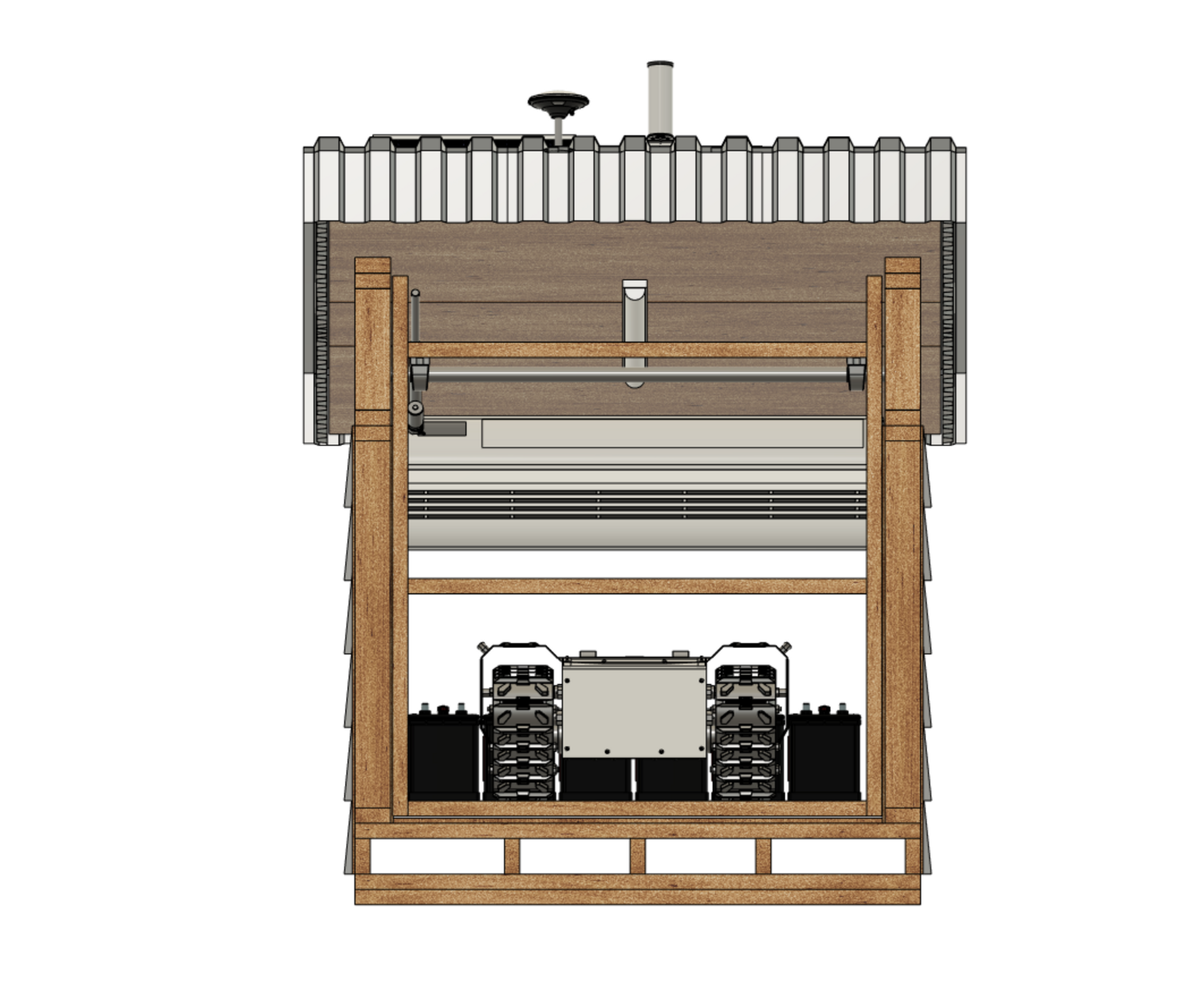

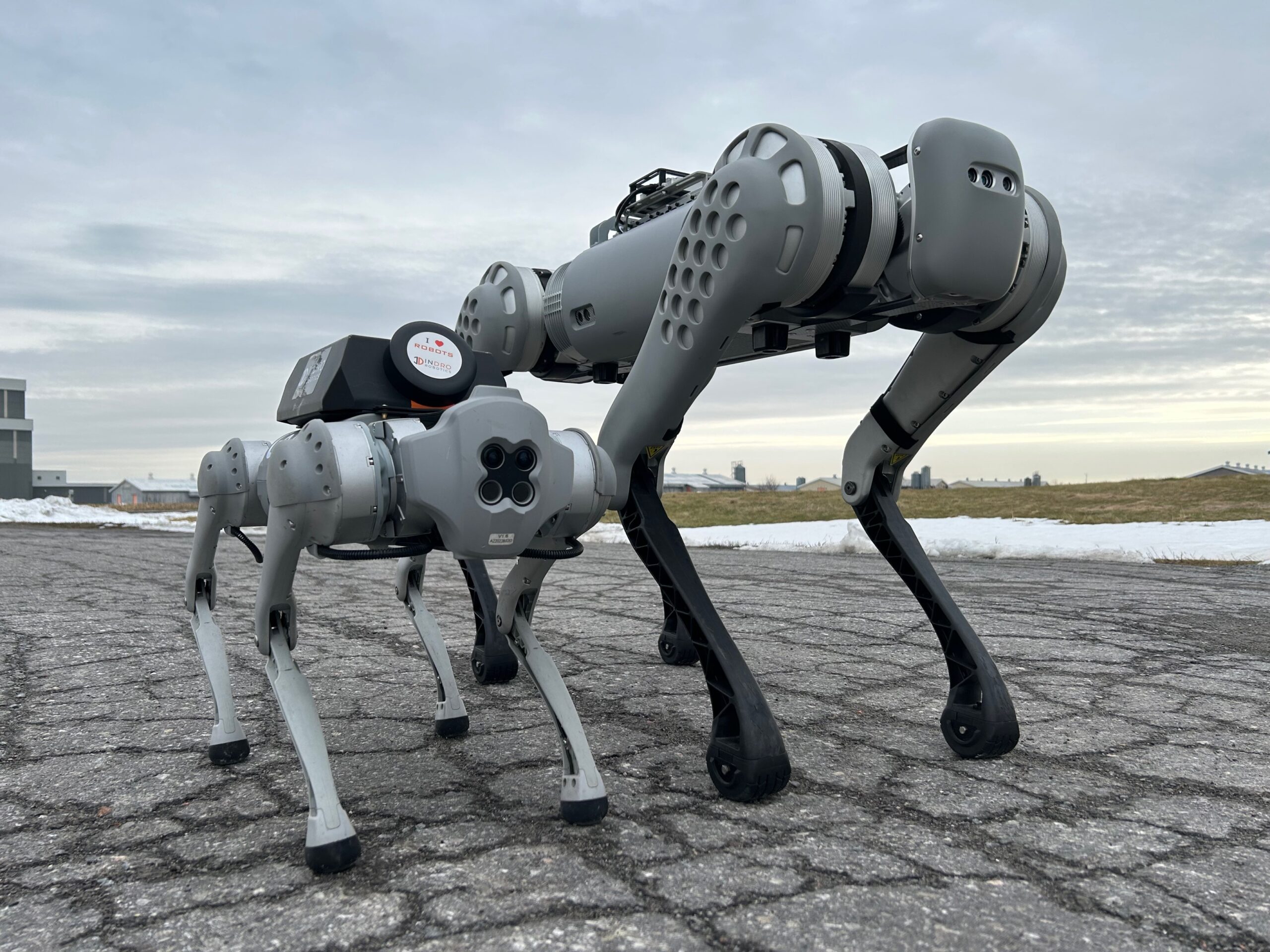

Engineering lead Arron Griffiths pulled together a design for a “dog house.” The intended occupant of the house is Sentinel, our remote inspection robot designed for electrical substations, solar farms, etc.

But why a dog house?

“Well, 90 per cent of robot deployments are short term – think two to four hours – and they tend take place in areas where humans aren’t nearby to check on and recharge the robot. So robots need a safe, warm, dry place where they can recharge.”

Sentinel is capable of recharging wirelessly, and using optical recognition to align itself properly with the charger. So why not have a little home where Sentinel can be protected from the elements? Arron’s design included solar panels to keep Sentinel fed, and a roof using plastic material in order to avoid any interference. There’s even an antenna on top, and an air-conditioner for those really dog day afternoons.

Arron’s design obviously took into account the dimensions of Sentinel, meaning this design is intended to become a real-world product. InDro will likely build its first dog house in Q3 of 2023.

Product renders

InDro is a distributor of Unitree robots (among other products). And while we always keep a few of their entry-level quadrupeds in stock, we generally ship orders for higher-end robots directly to the client (unless they want us to modify them).

sThat means we don’t have ultra high quality images of these products for marketing purposes. Stephan Tzolov decided he’d address this, dusting off some old (and impressive) skills in graphic production/design. He imported a CAD model, then worked wonders with virtual lighting, textures and more using Keyshot software.

“I liked flexing my creative muscles in a way that both provided something new and exciting for the team,” he says. “This also revitalizes the way in which we could showcase our robots and potential future/upcoming projects. Future development can include animations.”

Stephan has even included the InDro Backpack – which enables teleoperations over 4G and 5G and makes additional sensor integration a snap. The renders even show how the look of robots can be customised with skins for client branding.

We were really impressed with what Stephan pulled together. Look closely: Can you tell these are not actual photographs?

Big dog

By the way, not long after the Hack-a-Thon a Unitree B1 arrived at Area X.O. It’s a much larger robot than its sibling. Interestingly, Stephan’s renders look just as good – perhaps even better – than the real thing.

Simulations

Software simulations are highly useful in the R&D world. They can help engineers understand aerodynamics, stress – and much more – without using a physical object in the real world or waiting for the event to happen. And so a couple of staff members chose this area for the InDro Hack-a-Thon.

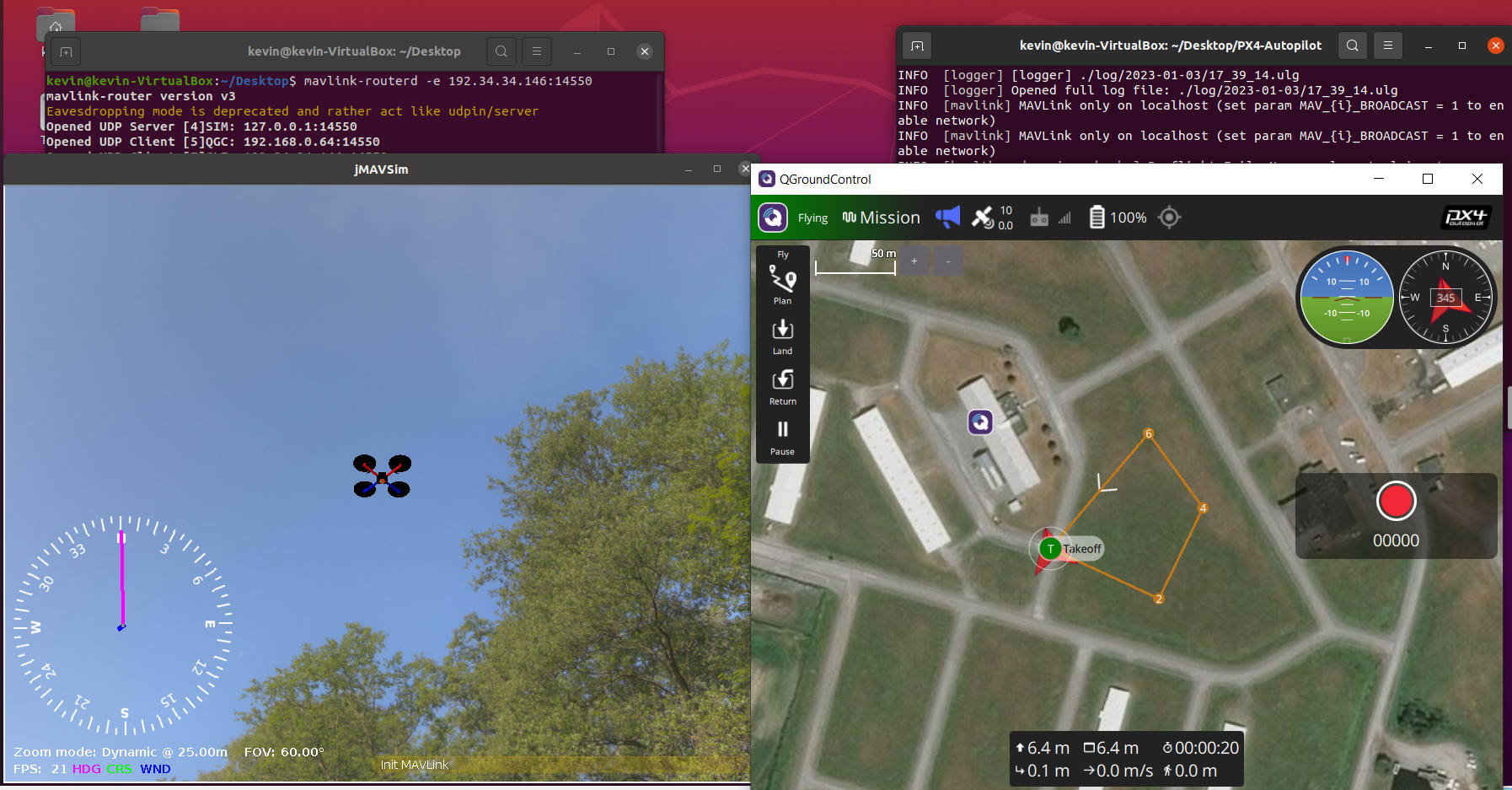

Area X.O’s Kaiwen Xu used the open-source software jMAVSim to create a simulator for the Pixhawk flight controller, the PX4. This flight controller is commonly used in Enterprise drones. But not all flight controllers are the same. For example, a DJI flight controller will respond slightly differently to inputs than a Pixhawk. Plus, the Pixhawk is commonly used in conjunction with Q Ground Control, or QGC, which has its own unique set of commands for programming flights.

“Pilot candidates and clients can practice flying in Software In the Loop (SWIL) environment before going out to flying a real drone,” says Kaiwen. “A typical use-case would be helping a new pilot learn how to arm, disarm, switch flight modes, change parameter settings – and get the feeling of controlling the sticks to operate the drone.”

The simulator could even be used to carry out pre-programmed autopilot flights.

Kaiwen did a successful realtime demo, carrying out a simulated flight. Here’s a mid-mission screengrab:

EVA drives in virtual space

The second simulation was prepared by Liam Dwyer, and involved our latest delivery robot.

ROLL-E 2.0 is the second generation of our delivery robot line. It has already been used in curbside pickup and home delivery trials with London Drugs. This second gen version is really slick looking, can carry up to 50kg of cargo, and is remotely teleoperated over 4G and 5G networks. It’s also somehow more feminine in appearance than the original ROLL-E – leading some staff to call it EVA (a name that might stick).

Though Liam can drive the physical ROLL-E 2.0 anytime, he thought it would be useful to create a simulated world for testing purposes. He used a graphical interface called RVIZ, which helps to visualize things in 3D space that use the Robot Operating System (ROS) software. Liam included proper inertia and collision values to make the simulation as realistic as possible, and operated it within Gazebo – an open-source, 3D robotic simulator.

Future uses of his creation include testing ROLL-E 2.0 virtually on various inclines and terrains, including testing its ability to handle curbs and other obstacles.

Saving search time…

InDro Robotics is a busy place, with operations in Victoria, Vancouver, Salt Spring Island and Area X.O in Ottawa. Because we’re an R&D company, you can imagine the amount of documentation, part orders, purchase requests, receipts, shipping waybills, etc.

Trust us, it’s a lot of stuff.

Being able to drill down and find specific documents is time-consuming. And that task frequently falls to Office Manager Panfei Gu. What if, she thought, there was a way to have software take on some of that burden?

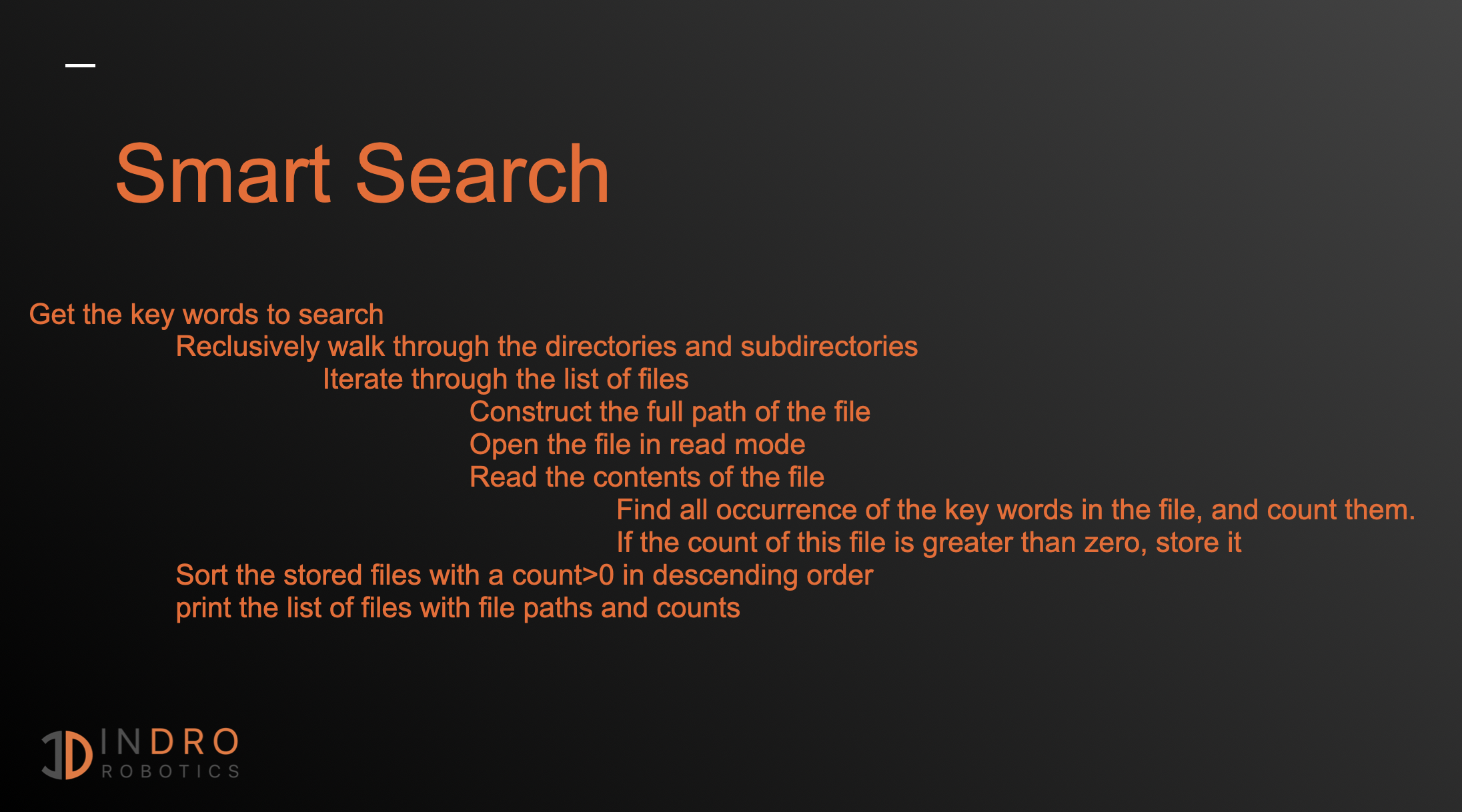

Panfei teamed up with Ella Hayashi from engineering. They quickly developed a plan. Ella would code a “Smart Search” that could parse its way through the various locations using keywords. The program works at the top directory searching every file in that directory and lower, opening folders as it goes. The Python script also was written so that if three keywords were entered, all three had to appear in the document before it would be displayed as a result.

The end result? A smarter way to search, and less time (and frustration) for Panfei in front of a monitor. Here’s a key page from their Power Point presentation, outlining some of the steps:

Downsizing

If you follow InDro, you’ll be aware of a device we call InDro Capsule. It’s essentially a module that vastly increases the capability of Enterprise drones using the Pixhawk flight controller. Those enhanced capabilities include:

- Remote teleoperations over 4G, 5G

- Dense data realtime downloads and uploads to the cloud

- Broadcasting drone ops location to traditional crewed aircraft

- Secure, encrypted data transmission and Command and Control

The first generation of this product, InDro Pilot, is the hexagonal box you see on our Wayfinder in this photo:

Shrinky, shrinky

There are advantages to making that capsule smaller and lighter. Reduced weight means greater flight efficiency. It also enables attaching this product to smaller drones.

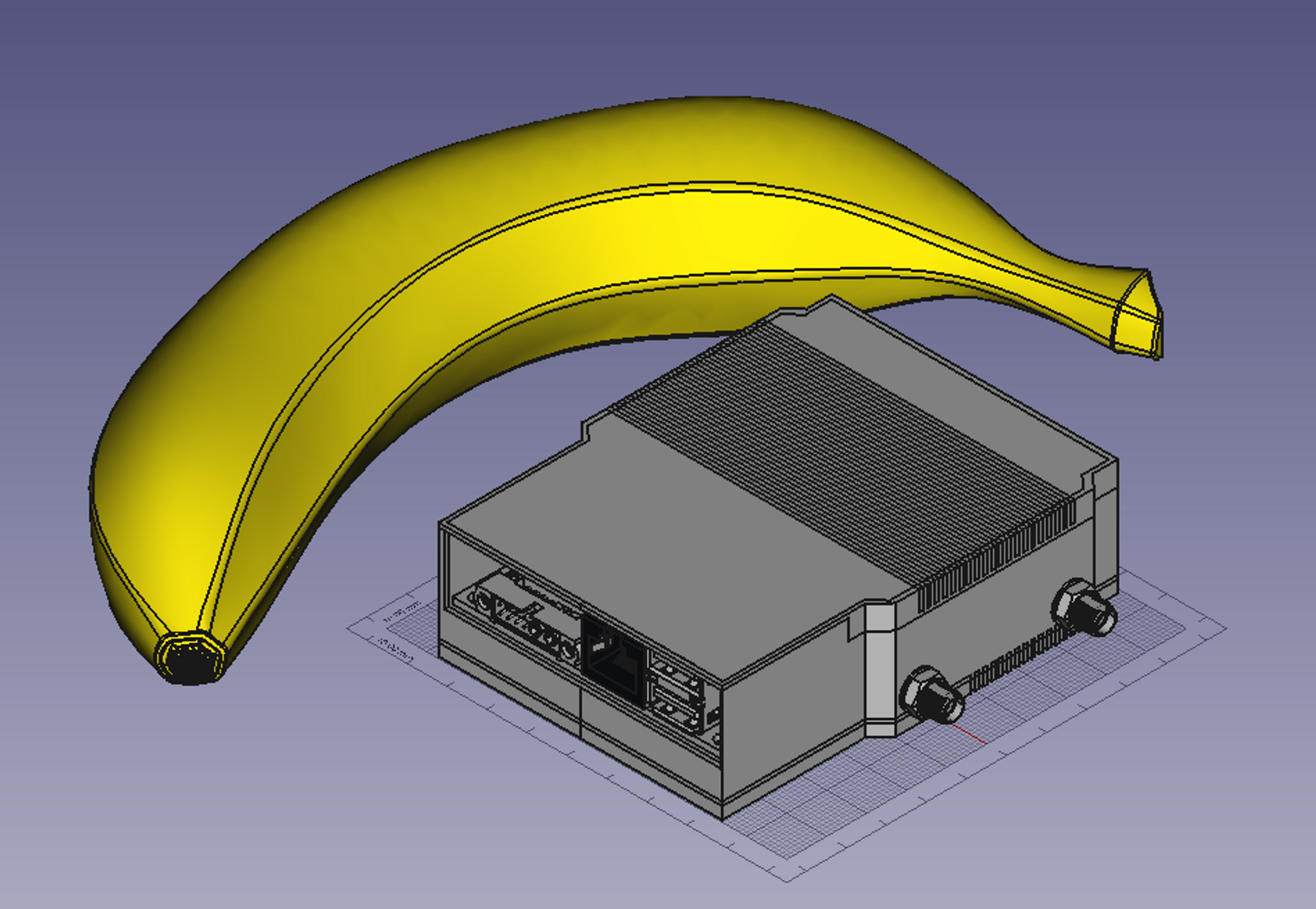

In fact, we’ve already created a downsized V 2.0 of this product. But InDro’s Peter Sherk wondered if we could get it even smaller. And so that was his project, trying to downsize this module even further to a minimal size and weight.

Interestingly, one of the most expensive components in his mini-capsule was finding a suitable connector cable that would work with the small version. We’d love to show you some of the detailed drawings and parts lists, but that would kind of give away the secret sauce of InDro Capsule.

So we’ll leave you with an image that gives you a sense of scale: The new and tiny InDro Capsule, sitting next to a standard sized banana:

Multitasking router

Many of InDro’s products are meant to be teleoperated remotely over 4G and 5G networks. In fact, all of our drones and ground robots are customized with this feature, enabling remote operations hundreds or even thousands of kilometres away. (We have one upcoming deployment where an InDro pilot based in Vancouver will be conducting regular missions a continent away.)

All of those products use a modem/router where a SIM card is inserted to enable communication over telecom networks. But here’s the thing: Some of our clients do not require remote teleoperation. Universities, R&D companies and more are often using these products, particularly ground robots, indoors or in very close quarters outdoors. Yet they must still purchase a SIM card and data plan to remotely control these robots through a computer dashboard.

Area X.O’s Tirth Gajera had a better idea: To flash the firmware of our most-used modem/router to enable it to operate over WiFi. Pretty much every facility (if not all) where these units are being used internally or within small outdoor confines has a local WiFi network. Upgrading the capabilities of the modem/router would save those clients money.

Tirth’s work also enables the modem to scan for local SSID (network names), allowing the correct network to be selected. That means products like our remote inspection robot Sentinel could be put to work using a local area network, rather than using a SIM card and network plan.

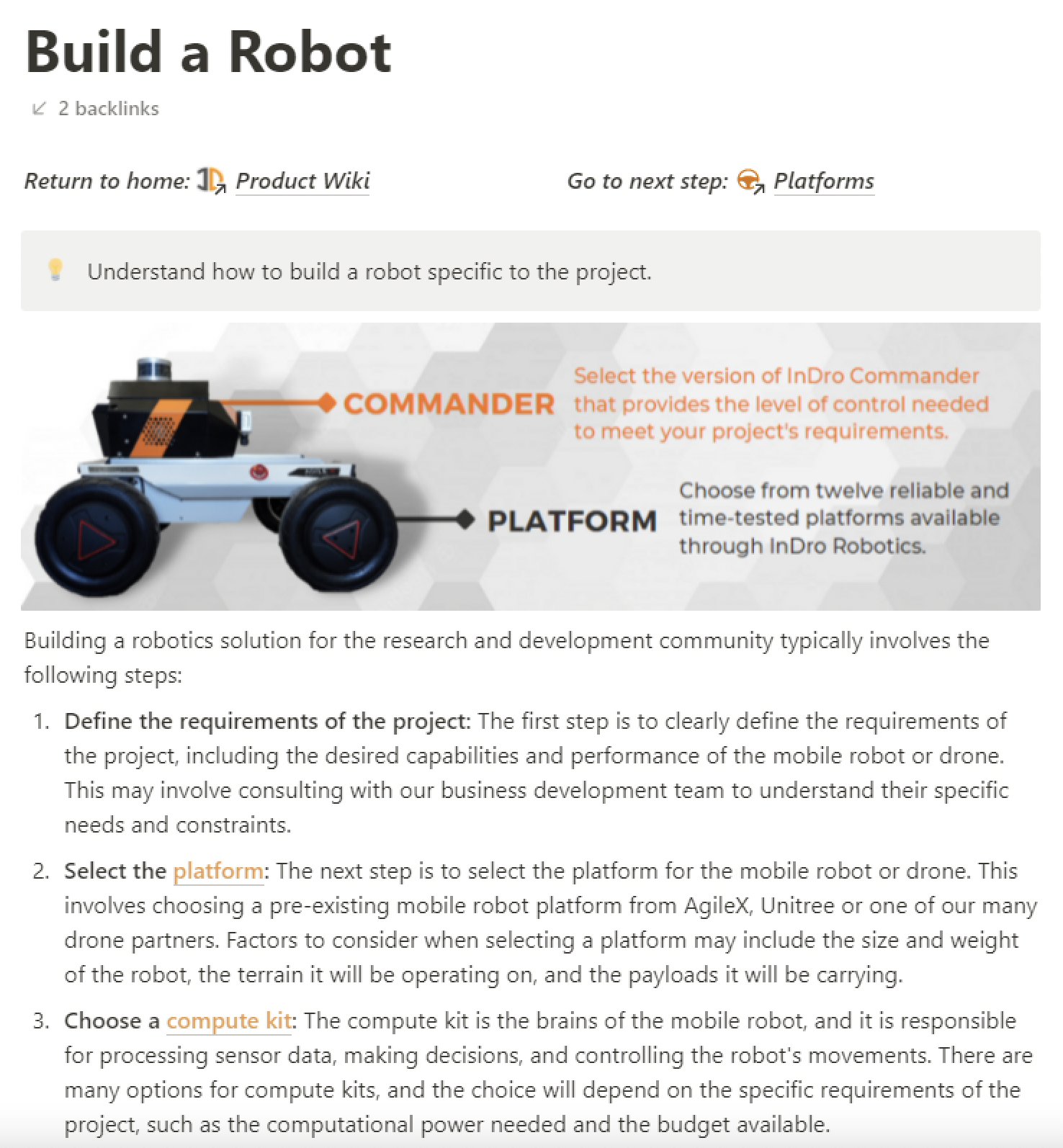

One-stop shopping

InDro now manufactures or resells a growing number of products. And many of those products themselves come in different iterations. For example, some clients want the Sentinel mentioned above to come equipped with a LiDAR sensor; others might want thermal and optical. We also resell – and modify – the Unitree line of quadruped robots. And more.

For the sales team, that has traditionally meant that data about specifications, custom integrations, images and costs are in different locations. As a result, getting a quick quote or answering a spec question for a customer requires some time looking things up. Wouldn’t it be easier, thought account executive Luke Corbeth (who handles the majority of sales), if we had a streamlined repository with all of this data easily accessible in one place?

Why yes. Yes, it would.

Luke built a highly structured database using workplace software Notion that does precisely that. It’s a secure platform, and allows Luke and others to quickly drill down to get the data or assets they need with minimal effort. We anticipate this will be a useful InDro tool moving forward.

Here’s a look at part of the overview of Luke’s project.

And the Winners Are…

Following the presentation, a vote was held. And here are the results, from First Place to Third:

- Peter Sherk, for solid plans to shrink down the InDro Capsule

- Arron Griffiths, for the Sentinel dog house

- Luke Corbeth for the sales and marketing database

Fourth went to Stephan Tzolov, for those amazing renders. Speaking of which, we’ll leave you with a bonus holiday greeting Stephan created as part of the package.

InDro’s Take

The annual Hack-a-Thon is now an established part of InDro work culture, and a fun and special event for the entire company. It’s amazing seeing what those with an engineering background – and even those without one – can pull together in a very short amount of time.

“This year’s Hack-a-Thon has once again produced products, processes and plans that will prove beneficial for InDro Robotics and its clients,” says CEO Philip Reece. “And while we do vote for ‘winners’ – every idea that came to the table has merit and potential use-cases. Kudos to everyone who took part, and I’m already looking forward to the 2023 edition.”